Description

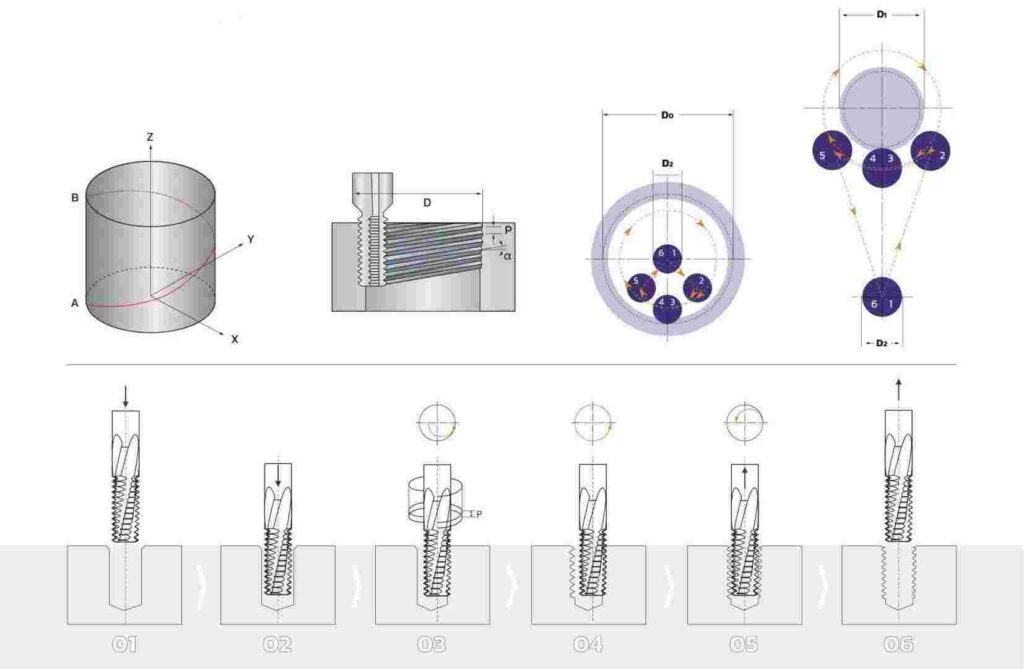

Thread milling produces threads with the circular ramping movement of a rotating tool. The lateral movement of the tool in one revolution creates the thread pitch.

Thread milling tool path will give right or left hand threads, using down-milling or up-milling. Always engage and retract the thread mill in a smooth path, i.e. roll in and out of cut. Thread milling requires machine tools which are capable of simultaneous movements on the X, Y and Z axes. The thread diameter is determined by the X and Y axis, while pitch is controlled by the Z axis.

Right-hand internal threads

All cutters are initially positioned as close as possible to the bottom of the hole, and then move anticlockwise in an upwards direction to ensure that down-milling is achieved.

Left-hand internal threads

Milling a left-hand thread follows in the opposite direction, from top to bottom, also in an anticlockwise path to ensure that down-milling is achieved.

A smaller cutting diameter will help to achieve higher quality threads. The cutter engagement will create a minute form error on the root of the thread profile. In internal thread milling applications, the relationship between threading diameter, cutting diameter and pitch will affect the true radial depth of cut,which becomes much larger than the chosen radial depth of cut. A larger true ae will increase the deviation in the root of the thread. To minimize the profile deviation, the cutter diameter should be no greater than 70% of the threading diameter.

Reviews

There are no reviews yet.