Carbide drills, a cornerstone in precision machining, come in two types—carbide drills with cooling holes and carbide drills without cooling holes. Both versions embody the cutting-edge capabilities of carbide tools, catering to diverse industrial needs with durability, precision, and performance at their core.

Categories

- Semi-open Straight Cutter

- T Slot Milling Cutter

- Bottom-processing Cutter

- Front and Back Chamfer

- V-Shaped Milling Cutter

- HPC Milling Cutter

- Center drill

- ZRN Milling Cutter

- Drilling Inserts

- Lollipop End Mill

- HM Series Square End Mill

- High Feed Milling Inserts

- CARBIDE REAMERS

- Thread milling

- Thread Inserts

- Micro Boring Tool

- Deep Hole Drilling

- Parting and Grooving inserts

- corn teeth

- Modular Drill Inserts

- Turning Inserts

- GM end mill

- Slot Mortising Bits

- Milling Inserts

- SPIRAL BITS AK44 Material

- TCT UP/Down Cut Spiral Bits

- Routers Bits

- Bottom Engraving Milling Cutte

- Engraving Bits 2F

- Carbide Inner corner

- Round Bottom Router Bit

- New Arrivals

- CNC Carbide End Mill

- CNC Carbide Drill

- CNC Carbide Insert

- CNC Carbide Rod

- Single Flute End Mill

- CNC Carbide Burr

- Turning Insert For steel parts processing

- Turning Inserts For CVD Double Coating

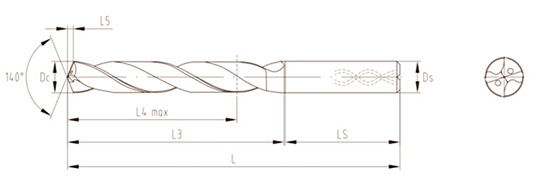

Featured Solide carbide Inner-coolant Drill Bit

use high-quality tungsten material, high-precision imported Germany Wlater CNC machine processing,

suitable for structural steel, alloy steel, stainless steel, cast iron and other common materials

“2 central water outlet holes, 30% longer life than external cooling under the same parameters.”

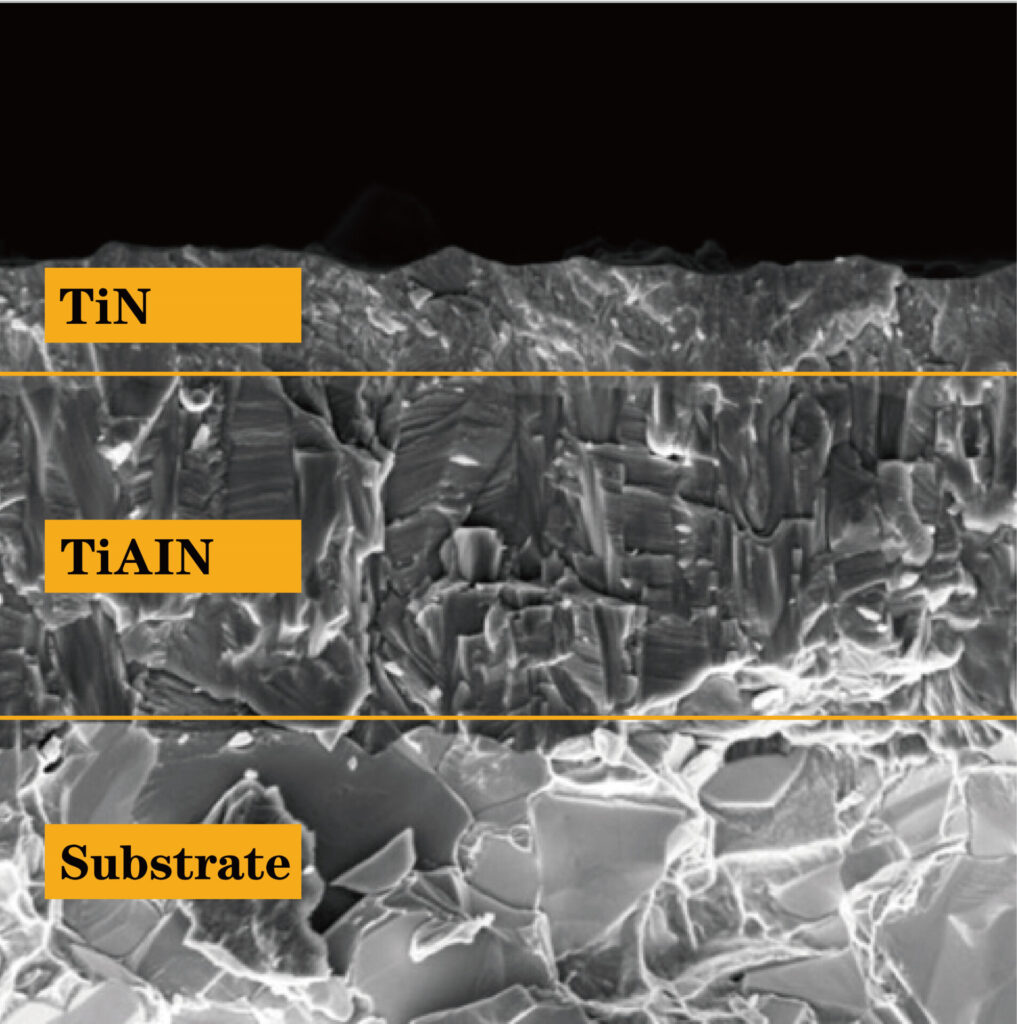

bottom of the substrate

-55% aluminum, 45% titanium

-thickness for 3.0 µm, TiAlN coated

withstand crescent moon wear and flank wear.

top of the substrate

-TiN coated

-thickness for 0.2 µm, TiAlN coated

Preventing the accumulation of chip lumps on the cutting flute.

manufacturing process

We have a complete production system in place that allows us to create high-grade milling cutters from start to finish. Our commitment to quality and precision is evident in every stage of the process, from pressing and passivation to coating and packaging.

Previous

Next