Description

Milling insert, also known simply as an insert, is a replaceable cutting tool element used in milling machines and machining centers.

Milling is a machining process where a rotating cutting tool removes material from a workpiece.

The milling insert is a crucial component in this process and is designed to perform specific cutting operations.

- Material: Milling inserts are typically made from hard materials like carbide, ceramics, or high-speed steel. The choice of material depends on the specific machining requirements and the type of material being cut.

- Geometry: Milling inserts come in various shapes and geometries, each designed for specific cutting tasks. Common insert shapes include square SNMX, round, octagonal, and diamond-shaped. The geometry of the insert influences factors like cutting speed, feed rate, and chip formation.

- Cutting Edges: HNMU Inserts have multiple cutting edges, allowing for extended tool life. When one edge becomes dull, the insert can be rotated or replaced with a new one, reducing downtime in machining operations.

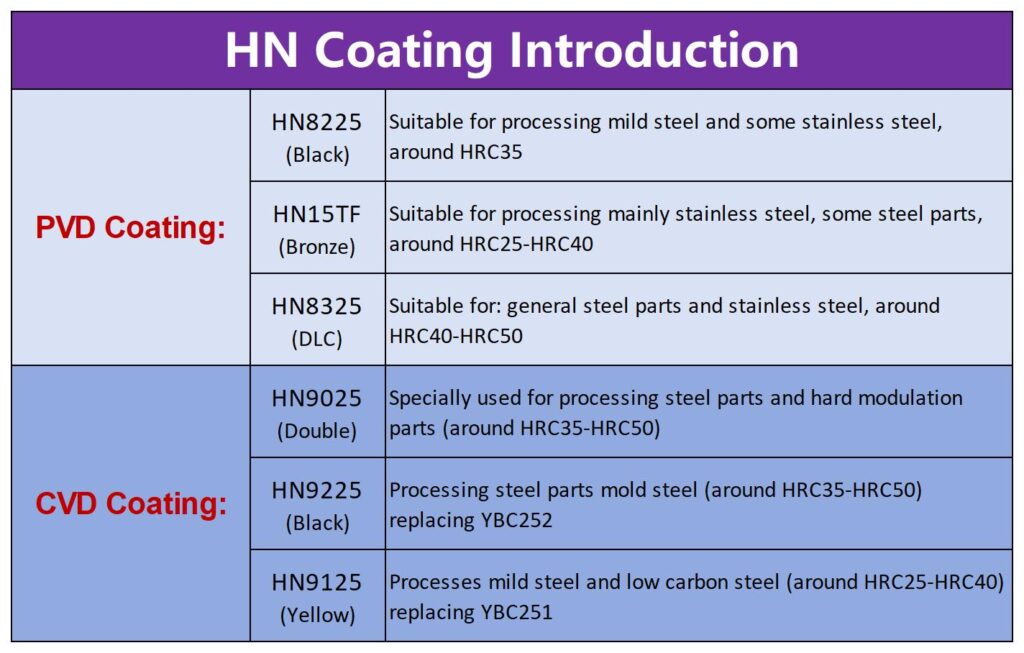

- Coating: Many milling inserts feature coatings to enhance their performance and durability. Common coatings include carbide, titanium nitride (TiN), titanium carbonitride (TiCN), and various combinations. Coatings help reduce friction, increase hardness, and improve resistance to wear.

- Application: Milling inserts are used in a variety of milling operations, such as face milling, shoulder milling, slot milling, and profile milling. Different insert types are designed for specific applications, ensuring optimal performance.

Reviews

There are no reviews yet.