Description

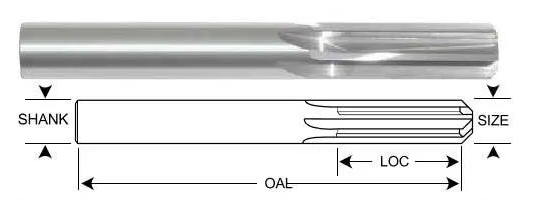

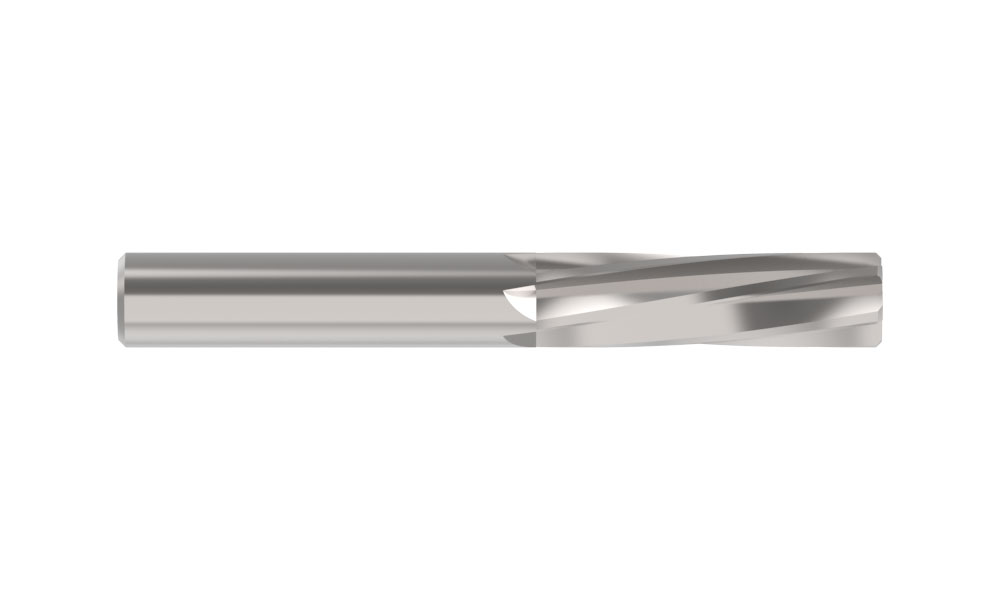

A reamer is a tool that is used to enlarge or finish holes that have been pre-drilled, bored, or cored in order to provide a high-quality finish and an accurate size.

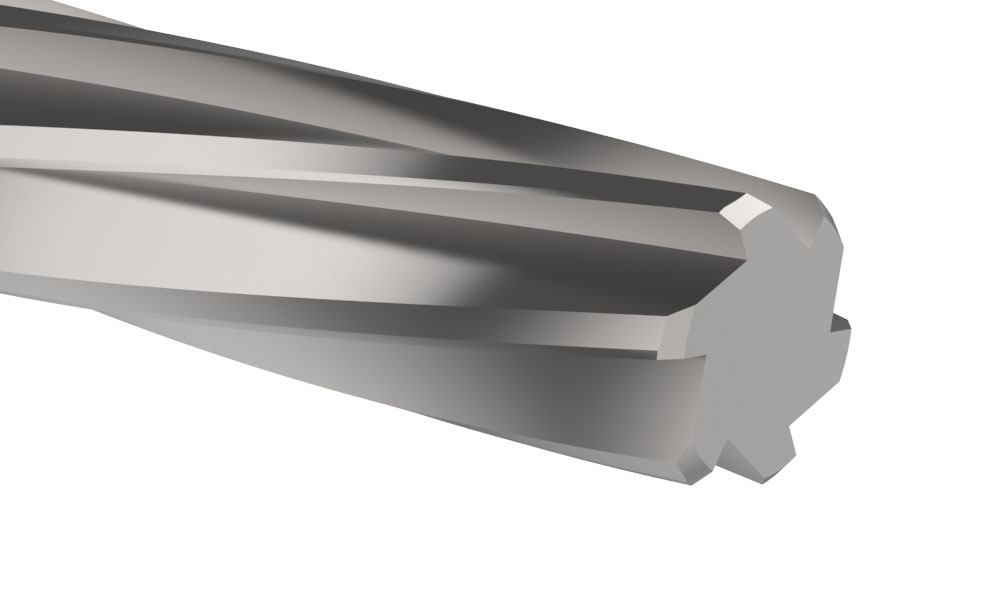

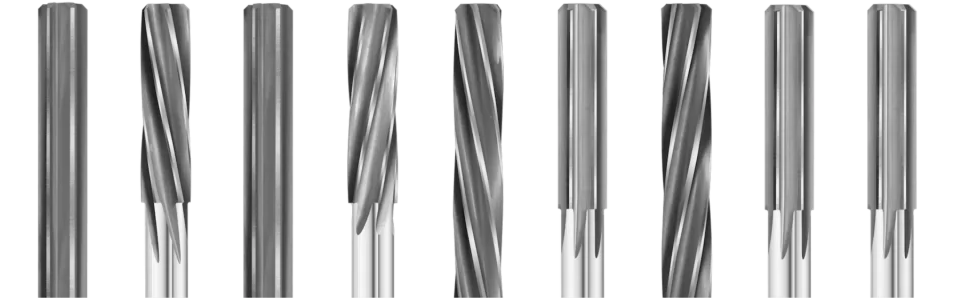

Reamer flutes are situated at the front of the device. Small chips are removed by passing along the reamer’s flutes. Flutes are classified into two types: straight and helical. Helix is further classified into four types: right hand, left hand, slow, and quick.

Straight fluted reamers are utilized for a range of materials and applications in general. The length will be determined by the application. The entering end will be tapered somewhat. This causes the flute to self-center as it enters the hole, while the larger section of the flute will have a constant diameter to allow for the growth. Because right hand spiral reamers have a tendency to suck chips and coolant out of the hole, a right hand kind of helix should never be used on a tapered reamer; otherwise, the reamer may wedge, resulting in catastrophic tool failure.

Left-hand spiral reamers have a propensity to push chips and coolant in front of the cut, allowing coolant to enter the hole and the reamer to exit. On tapered reamers, a left hand spiral can be employed to aid prevent grasping and binding. They should not be used in blind hole applications because the chips will pack at the bottom of the hole and prevent the reamer from cutting all the way to the bottom. There are four crucial criteria to consider when choosing a flute: flute diameter and length, pilot diameter and length, number of flutes, and flute depth.

Reviews

There are no reviews yet.