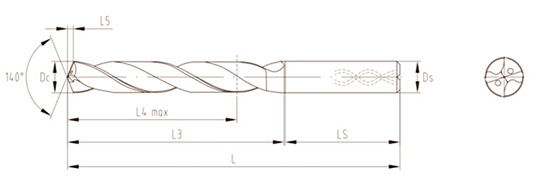

Featured Solide carbide Inner-coolant Drill Bit

use high-quality tungsten material, high-precision imported Germany Wlater CNC machine processing,

suitable for structural steel, alloy steel, stainless steel, cast iron and other common materials

“2 central water outlet holes, 30% longer life than external cooling under the same parameters.”

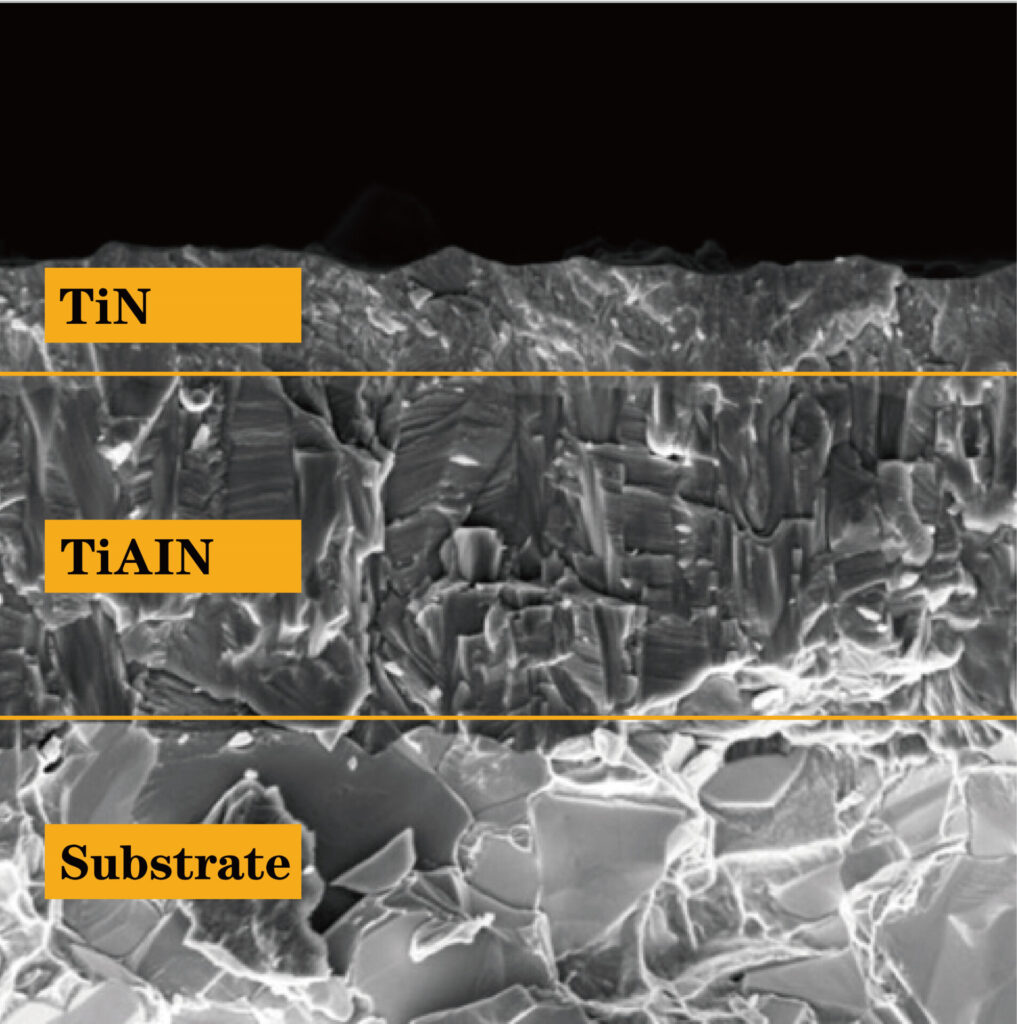

bottom of the substrate

-55% aluminum, 45% titanium

-thickness for 3.0 µm, TiAlN coated

withstand crescent moon wear and flank wear.

top of the substrate

-TiN coated

-thickness for 0.2 µm, TiAlN coated

Preventing the accumulation of chip lumps.

Carbide drills, a cornerstone in precision machining, come in two types—carbide drills with cooling holes and carbide drills without cooling holes. Both versions embody the cutting-edge capabilities of carbide tools, catering to diverse industrial needs with durability, precision, and performance at their core.

manufacturing process

- Semi-open Straight Cutter

- T Slot Milling Cutter

- Bottom-processing Cutter

- Front and Back Chamfer

- V-Shaped Milling Cutter

- HPC Milling Cutter

- Center drill

- ZRN Milling Cutter

- Drilling Inserts

- Lollipop End Mill

- HM Series Square End Mill

- High Feed Milling Inserts

- CARBIDE REAMERS

- Thread milling

- Thread Inserts

- Micro Boring Tool

- Deep Hole Drilling

- Parting and Grooving inserts

- corn teeth

- Modular Drill Inserts

- Turning Inserts

- GM end mill

- Slot Mortising Bits

- Milling Inserts

- SPIRAL BITS AK44 Material

- TCT UP/Down Cut Spiral Bits

- Routers Bits

- Bottom Engraving Milling Cutte

- Engraving Bits 2F

- Carbide Inner corner

- Round Bottom Router Bit

- New Arrivals

- CNC Carbide End Mill

- CNC Carbide Drill

- CNC Carbide Insert

- CNC Carbide Rod

- Single Flute End Mill

- CNC Carbide Burr

- Turning Insert For steel parts processing

- Turning Inserts For CVD Double Coating