Imagine this scenario: You are in the middle of a high-speed machining process, and your cutting tool just broke, resulting in a screeching stop to the production process. The culprit? Incorrect choice of material for your CNC turning inserts. This is an expensive error that occurs more frequently than you might imagine, but which can be avoided entirely when you know more about insert materials. The distinction between a carbide insert and a ceramic blade is not purely academic; it can either make or break your success in machining.

Regardless of whether you are cutting soft aluminum or hardened steel, the selection of the insert material can dictate everything about the cutting speed, tool life, and so on. The knowledge of how blade materials are classified is not only useful, but an absolute must-have for anybody serious about efficiency and cost in machining.

What are CNC Turning Inserts and Material Classification?

The CNC turning inserts are the very epitome of modern-day machining technology, and it is the material composition of the same that dictates factors like the cutting speed as well as the tool life. The grouping of blade materials has changed drastically over the last few decades, and manufacturers have developed exclusive compounds to suit particular challenges during the machining process.

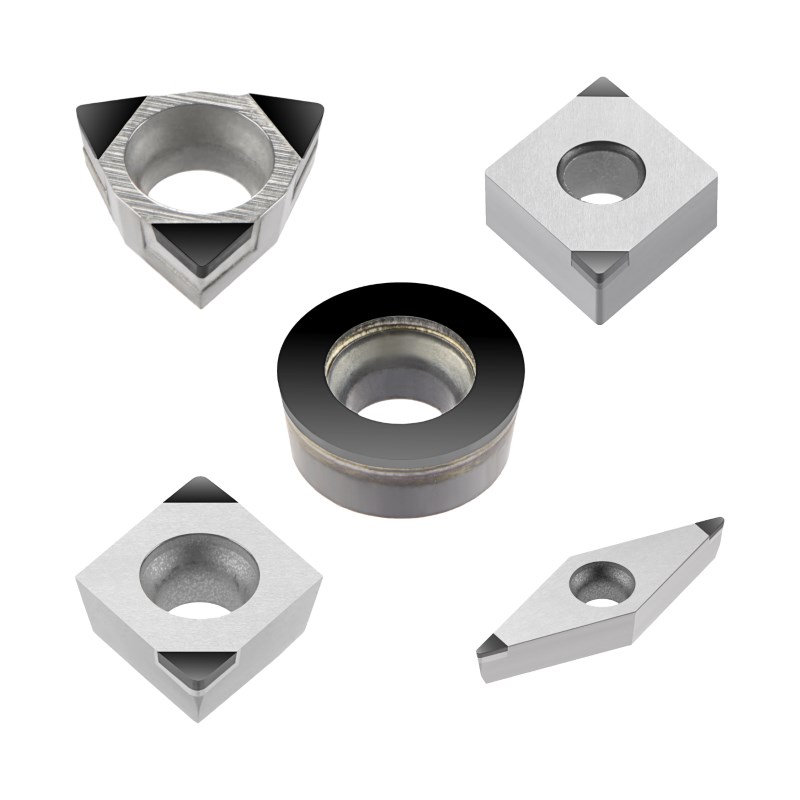

CNC turning tools are somewhat more distinctly classified into four types: carbide, ceramic, cermet and CBN (cubic boron nitride). Each of the categories possesses different advantages and disadvantages, and this aspect predetermines the sphere of their application. This knowledge of the basic differences will help the machinists in selecting the right tool which will serve their purpose.

The most important properties of the materials are such that concern hardness, toughness, thermal conductivity, and chemical stability. The durability supports the wear resistance and the resilience influences the capacity of the insert to manage interrupted cuts and shock loads ability. The thermal conductivity affects the ability of the insert to dissipate heat, and chemical stability ensures no undesired reactions with the materials of the workpieces.

Insert materials have been stretched to the limit by today’s manufacturing needs. The use of high-speed machining, exotic alloys, and precision demands has generated the requirement for specialized materials capable of performing under extreme conditions. This has brought the invention of coated inserts, composite materials, and ultra-hard substances that would have never been thought of decades ago.

Carbide Inserts

The CNC turning inserts market is dominated by carbide inserts due to their balanced performance characteristics. Tool materials consist of tungsten carbide particles liberally mixed with cobalt to form a substance that is hard and tough enough to handle most machining tasks.

Process of Manufacture

Cemented carbide blade inserts are produced by powder metallurgy methods, which have been developed over several years. The powder of tungsten carbide is mixed with cobalt binder, pressed into shape, and sintered at a temperature over 1400°C. The result is a homogenous microstructure which offers equal performance throughout the cutting edge.

The cobalt content varies between 3% and 25%, depending on the required application. The reduced cobalt content produces harder, wear-resistant inserts that can be used in high-speed applications on softer materials. The toughness increases with a higher cobalt content, and these inserts are preferred for use in interrupted cuts and under shock loads.

Carbide Grade Classifications

The varying grades of carbide are used in different machining applications, characterized by a closely defined composition and microstructure. The ISO structure for organizing carbide types is founded on a blend of letters and numerals. P grades are steel machining, M grades are general purpose, and K grades are cast iron and non-ferrous.

Fine-grain carbides are very well suited to the finishing operations when the quality of the surface is of prime importance. The grain size is small, which makes a sharp and stable cutting edge that results in good surface finishes. These grades, however, trade off some toughness in the name of better wear resistance and edge sharpness.

Coarse-grain types are used in heavy roughing cuts, wherein the greatest toughness is needed. The greater grain structure also offers greater resistance to cracking and can be fed at a higher rate without chipping. These grades are excellent when a large quantity of material needs to be removed in a short period, but they are not the best choice when a good final surface finish is required.

Carbide Grade | Grain Size | Cobalt Content | Best Applications |

Fine Grain | 0.5-1.0 μm | 6-8% | Finishing, high-speed cutting |

Medium Grain | 1.0-2.0 μm | 8-12% | General-purpose machining |

Coarse Grain | 2.0-5.0 μm | 12-15% | Heavy roughing, interrupted cuts |

Extra Coarse | 5.0+ μm | 15-25% | Extreme shock loads, mining tools |

Ceramic Blade Technology and High-Temperature Performance

Ceramic blade inserts are also a very important development in cutting tool technology, having better performance in high-speed machining applications. These CNC turning inserts also retain their cutting capacity in temperatures that would otherwise ruin carbide tools, making them suitable for use in demanding applications.

Pure Aluminum Oxide Ceramics

Ceramic insert technology is based on aluminum oxide, offering outstanding wear and thermal stability. Pure aluminum oxide ceramics are especially effective in machining cast iron, hardened steels, and super Alloys at cutting speeds that would rapidly wear carbide inserts.

The white ceramics will provide chemical inertness, preventing the formation of built-up edges on most materials. The low thermal conductivity and high melting point are useful in preserving the cutting edges integrity even when subjected to high heat generation. Pure ceramics however may be brittle and they need stable machining conditions in order to give the best.

Silicon Nitride Reinforced Ceramics

Additions of silicon nitride produce stronger ceramic inserts capable of withstanding more demanding machining conditions. The whisker like particles of silicon nitride serve as crack stoppers and they arrest the propagation of fracture through the ceramic matrix. This enhances their toughness allowing silicon nitride ceramics to be applied in interrupted cuts and less stiff machining arrangements.

These gray ceramics sit between pure ceramics and other materials, offering better versatility without losing too much hardness. They are suitable in semi-finishing and finishing tasks where productivity and the surface finish are of concern.

Mixed Ceramic Compositions

High technology ceramic formulations further aluminum oxide with other compounds such as titanium carbide or silicon carbide to maximize certain properties. These composite ceramics combine hardness, toughness, and thermal conductivity to suit the application-specific demands.

The addition of titanium carbide enhances the electrical conductivity of the ceramic, creating a suitable material for electrical discharge machining. The addition of silicon carbide provides an improvement in thermal shock resistance, allowing the inserts to cope with faster temperature changes compared to pure ceramics.

Cermet Inserts

A new insert material technology is the use of Cermet which is a mixture of ceramic and metallic parts. Cermet inserts have a name derived from ceramic-metal, and they have properties considered to be between those of traditional carbide and ceramic materials.

Composition and Manufacturing

The hard phase in cermet inserts is usually titanium carbide, titanium nitride or titanium carbonitride, and the metallic binder is nickel or cobalt. Production Powder metallurgy methods are used, somewhat analogous to those used in making carbide, except that the temperature and atmosphere conditions are different.

The ceramic phase offers hardness, wear resistance, toughness, and thermal conductivity, while the metallic binder provides strength. Combining this results in inserts that are harder than carbide, but tougher than ceramics, so can be used where both qualities are needed.

Performance Characteristics

Cermet inserts perform well in steels and stainless steels finishing operations where the quality of the surface finish is vital. They last longer with keen cutting edges than carbide inserts and they give excellent crater wear resistance. The excellent hardness enables them to have greater cutting speeds compared to carbide and the metallic binder eliminates the brittleness that characterizes the pure ceramics.

These inserts are very effective where there is a constant machining process with continuous cuts. They are less well suited to interrupted cutting, or to applications where there is a lot of vibration, because the ceramic part may still tend to chip under shock loads.

Cermets thermal properties give them an application in high-speed finishing processes. They are able to run at carbide to ceramic cutting speed range with acceptable quality of surface finish. These give them popularity in automated machining processes where reliability of performance is important.

CBN Inserts

The cubic boron nitride inserts are the advancement of cut tool technology to machine hard materials. CBN is considered the second hardest substance known to man surpassed only by diamond and it also retains its properties at a much higher temperature than diamond.

Material Properties and Manufacturing

CBN inserts are produced by means of high pressure and high temperature technology which produces artificial cubic boron nitride crystals. Such crystals are next united with the aid of ceramic or metallic binders to form cutting tool inserts. The product thus obtained is very hard and thermally stable.

CBN offers outstanding wear resistance to ferrous materials due to its crystal structure that is unlike any other. At high temperatures, CBN does not have any chemical reaction with iron and this property makes it suitable in machining hardened steels and cast irons unlike diamond. It is this chemical stability that enables CBN inserts to retain their cutting edge even when a lot of heat is generated.

Applications and Performance Benefits

CBN inserts shine in hard turning where they are used in machining materials that are higher than 45 HRC. These inserts have a tendency of substituting grinding operations with considerable gains in productivity and high quality surface finishes. Hard material machining at sensible rates has transformed production of parts such as gears, bearings and hydraulic parts.

Combined with very high cutting speeds on hard materials, CBN is extraordinarily hard. The feed rates may be greater than those of grinding processes and the single-point cutting action gives better surface finishes. Such combination of speed and quality makes the CBN inserts economical to use though they are expensive to purchase.

Economic Considerations

Although CBN inserts are much more expensive than carbide options, their tool life and productivity advantages frequently make the expense worth while. In hard turning, one CBN insert can last 10-50 times longer than carbide insert, cutting down tool changing downtime and labor expenses dramatically.

Even CBN inserts are even more economically interesting, because they allow to avoid secondary operations such as grinding. Components may be turned to final size and finish in one operation, handling and set up time is minimised, as also is the quality control.

Specialized Materials and Coating Classifications

Blade materials are classified beyond the simple substrate materials to encompass a wide variety of coating technologies and application specific compounds that broaden performance in a given application.

Diamond Coated and PCD Inserts

There are two broad types of diamond technology; chemical vapor deposition (CVD) diamond coatings and polycrystalline diamond (PCD) inserts. CVD diamond coatings deposited on carbide substrates take a thin layer of synthetic diamond, offering the hardness of diamond with some of the toughness of the substrate.

PCD inserts incorporate diamonds particles that are joined to form cutting edges that have a superior wear resistance. These inserts are excellent when cutting aluminum, copper and composite materials and they give mirror like finish on surfaces and exceptionally long tool life. They are however; not applicable on ferrous materials because of chemical reactivity at cutting temperatures.

Diamond tools are still very expensive to manufacture, although in many non-ferrous applications they may be worth the outlay. When machining aluminum, a single PCD insert may last dozens of carbide inserts, and thus may be economical to use in high volume manufacture.

Coating Technologies and Systems

With modern coating technology, the performance of inserts has revolutionized by depositing thin layering of wear-resistant materials on the substrate surfaces. These coatings safeguard the base material and at the same time offer certain performance advantages that enhance tool life and efficiency of machining.

Titanium based coatings such as TiN, TiCN and TiAlN offer various hardness-lubricity-thermal stability combinations. The various types of coating have their benefits in different area of use, like general purpose machining, and high speed machining.

Multi-layer coating systems are used to compliment the overall performance by using various materials. A typical complex coating would consist of a titanium nitride underlying layer to assure adhesion, an aluminum oxide intermediate layer to assure thermal barriers and a titanium nitride top layer to assure lubricity and wear resistance.

Specialized Insert Geometries

The geometry is inserted in collaboration with the selection of materials to maximize cutting. The positive rake angles offer less cutting forces, and likewise cut weaker edges, where the negative rake angles offer edges that are stronger, but at the price of increased cutting forces.

The design of chip breakers regulates the chip formations and evacuations avoiding the long stringy chips that may complicated automated machining. It is found that different chip breaker patterns are more suited to certain materials and cutting conditions and hence geometry selection is as important as the material selection.

Material Selection Guide for Optimal CNC Tool Selection

When determining the appropriate material to use in CNC turning inserts, several factors ought to be put into serious consideration such as the workpiece material, machining parameters and economic limitations. This decision chain has great impacts on the productivity, cost/part and the quality of machining.

Workpiece Material Considerations

The selection criterion of the CNC tools is mostly dependent on the hardness and the composition of the workpiece material. Uncoated sharp carbide or diamond inserts are suitable to soft materials such as aluminum and brass which can hold a sharp edge. These materials do not cause too much heat and this means that high cutting rates can be used provided that the tool materials are right.

Medium-hardness steels are suitable to use with coated carbide inserts, which have adequate wear resistance along with crater wear resistance. The coatings are effective in dissipating heat and in inhibiting chemical reactions between the tool and the work piece thereby greatly increasing tool life, compared to uncoated tools.

It also has to do with hard materials that are beyond 45 HRC which need special materials such as ceramic or CBN inserts to machine efficiently. The conventional carbide tools also wear out too fast on hard materials and thus the more expensive tools are more economical in the long term use.

Machining Condition Requirements

The needs in cutting speed affect the choice of materials greatly due to the enormous difference in the temperatures restrictions of various materials. The high-speed operation is associated with a lot of heat, and therefore the material used should have a high thermal stability such as ceramics or coated carbides that would not change their properties when subjected to high temperatures.

Material selection is influenced to a large extent by the stability of the machining setup. Brittle materials such as ceramics which have better wear resistance can be used with good effect in rigid arrangements where little vibration is suffered. carbide or cermet inserts are more suitable in less rigid systems that need a much tougher material that is not likely to fracture due to vibrations and shock loads.

Availability of coolant and its type also affects the selection of material. Flood coolant enables the use of materials which would otherwise be overheated and dry machining necessitates materials with better thermal characteristics. Certain materials work better with certain types of coolant, which further complicates the choosing process.

Economic and Productivity Factors

Machining cost does not only consider the insert cost but also considers machine time, labor cost as well as overhead cost. Exotic materials such as CBN or diamond are more expensive up front, but may actually work out to be less expensive overall due to their improved performance which can contribute to lower cost per part due to higher productivity and/or less downtime.

The life of the tools has to be taken into consideration, where the high price should be counterbalanced by the frequency of replacement. A higher cost insert that performs five times longer than a lower cost insert offers a better value when the performance differences warrants the additional costs. The calculation is more complicated in the case when the cost of a tool change and machine downtime are taken into account.

Material selection is also informed by surface finish requirements whereby there are those materials that inherently give better finishes than others. Applications where a high quality of surface finish is important can easily validate the use of expensive materials should they be more so, since they can obviate secondary finishing processes.

Conclusion

The subject on the classification of blade material used in CNC turning insert is core to effective machining process. These four key types – carbide, ceramic, cermet and CBN – have their own distinct benefits that make them convenient to be applied in certain areas. CEmented carbide blade technology is still considered the workhorse of most operations and ceramic blade technology is best in high-speed applications.

Seven advanced materials such as CBN extend the limits of hard turning operation. Intelligent selection of CNC tools takes into account a combined effect of workpiece, cutting conditions and economics. Manufacturers can also maximize productivity, minimize costs and realize better results by selecting insert materials that match application demands. Further evolution of coating technologies and special compositions hold the promise of even greater success in the future machining tasks.