Carbide end mills are costly instruments that are required in the majority of great industrial milling applications. Different carbide end mills serve different functions – finishing, roughing, material-specific applications, and so on – and it is critical that you utilize them effectively to safeguard your investment and get the most out of your equipment. These suggestions might assist you in purchasing the right end mill for your unique application.

- Select the Appropriate Cemented Carbide Material

Carbide is the most often utilized material in the production of carbide end mills. The tungsten carbide grains are fused into a solid cobalt metal matrix. Longer tool life and reduced cycle times readily justify the extra cost in these applications. This material is harder than high-speed steel, although its toughness is not as good. Higher hardness levels give better wear resistance, while lower toughness levels make it more prone to breaking and chipping.

Smaller tungsten carbide grain sizes, in general, allow for the production of carbides with finer microstructures. A precondition for this is the inhibition of grain expansion during the sintering process with the addition of appropriate doping (process of introducing certain impurity atoms) components in the appropriate proportion, according to the cobalt concentration. The phrase “cemented carbide” refers to the fact that the grains of metal carbide are “cemented” in the matrix of the binder metal. The fusing process is known as “liquid phase sintering,” or simply “sintering.” Carbide is recommended in CNC machine tools that demand faster speeds, fewer tool changes, and better productivity.

The cobalt concentration is decided by the carbide’s requisite performance standards. Because a carbide’s specific surface relies on its grain size, a finely grained carbide may absorb more binder than a coarsely grained TC. Toughness (TRS) increases as cobalt concentration increases, whereas hardness and wear resistance decrease. Reduce the carbide grain size to counteract the opposing growth of the two desired criteria, hardness and toughness. The outcome is improved hardness because to the finer grain structure of the carbide, which also allows for a high binding metal content since the grain structure provides a wide surface area on which to bind: it also generates a high toughness. As a result, superfine grain carbide grades provide improved hardness while retaining toughness.

| HUANA Grade | ISO Grade | Grain Size | Cobalt Content | Densiy | Hardness | TRS | Application |

| um | % | g/㎤ | HRA | N/㎟ | |||

| HN304F | K20-K30 | 0.7 | 10 | 14.45 | 91.8 | 4000 | Grade for roughing and semi-finishing milling of heat-treated steel,common alloy steel,cast iron and other soft material below HRC45.Superior microstructure by the customized powder of high quality from H.C.Starck,with allows the particle size distribution to be centralized with better stability and wear resistance. |

| HN401 | k30-k40 | 0.6 | 12 | 14.18 | 92.4 | 4000 | General processing grade for material below HRC50.Suitable for semi-finishing and finishing milling of non-ferrous metal, common die steel, aluminum alloy and materials with uniform structure. |

| HN404 | K30-K40 | 0.6 | 12 | 14.25 | 92.4 | 4200 | Grade for roughing and semi-finishing milling of material(HRC45-52),including stainless steel,aluminum alloy,alloy steel,non-ferrous metal.Superior microstructure by the customized powder of high quality from H.C.Starck,which allows the particle size distribution to be centralized with better stability and wear resistance. |

| HN204N | K10-K20 | 0.2 | 9 | 14.4 | 93.6 | 4500 | Excellent grade for material below HRC60 such as hardened steel. Also suitable for non-alloy metals, high hard plastics, non-alloy steel, reinforced fiber composite materials, titanium alloy materials,etc., and is widely used in the processing of high speed, high hardness and high wear -resistant materials.Application for high speed cutting tools. The ultra -high toughness allowed by the customized WC powder of nano-particle from H.C.Starck. |

| HN104U | K05-K10 | 0.4 | 6 | 14.75 | 93.8 | 4200 | Grade for mills and drills with 0.4mm≤D≤1.6mm.Superior microstructure by the customized powder of high quality from H.C.Starck, which allows the particle size distribution to be centralized with better stability and wear resistance. |

- Choose Suitable Milling Cutters

When selecting a milling cutter, strive to match the milling cutter’s size to the surface size of the workpiece to be treated. End mills are typically utilized in production for the peripheral contour processing of flat workpieces; cemented carbide milling cutters are chosen for milling planes; and carbide end mills are favored for processing bosses and grooves. in manufacturing Corn cutters with carbide inserts are suggested for rough cutting the surface of the blank or hole; for some three-dimensional profiles and changeable bevel contour contours, utilize ball end milling cutters, ring cutters, and tapered milling cutters.

Carbide mill cutters are harder than high-speed steel, but not as strong. Higher stiffness gives better wear resistance, but lower strength makes it more prone to cracking and peeling. In powders and non-metallic processes, it is made up of metal carbide, tungsten carbide, titanium carbide, and cobalt-based metal binders. The following are its primary characteristics. It can endure high temperatures while maintaining decent cutting effectiveness at temperatures ranging from 800 to 10000 degrees Celsius. Cutting using a carbide mill cutter can be 4-8 times quicker than cutting with an HSS. Good abrasion resistance and hardness at room temperature. Low bending strength, low toughness, difficult to sharpen, and extremely quickly.

- Ball Cutter

It’s also known as a ball-nosed cutter. Ball cutters have a hemispherical end form. It is utilized to lessen stress focus. It can also carve three-dimensional forms.

- Roughing End Milling Cutter

Roughing mills are also referred to as “Pippa” cutters. These cutters work admirably even under the most difficult operating circumstances. It is used to extract vast volumes of material, as the names imply. These cutters have a wavy tooth. These cutters produce very tiny chips with a rough surface finish.

- Periphery Milling Cutter

When the teeth of the cuts are present on the radius of the circular disc, it is referred to as a circumferential mill cutter. Only horizontal mill machines may employ perimeter mill cutters.

- Side Milling Cutter

A side mill cutter is a kind of cutter with cutting teeth on both the perimeter and the face or end. This Cutter is mostly utilized in strand milling and face milling activities. It may also be used to cut slots and combine deep and thin slots.

- Face Milling Cutter

Face mill cutters feature a large cutter body with many mechanically fastened insertion tools. By creating radially deep and axially thin cuts, a substantial amount of material is removed. The cutter body diameter is determined by the length of the workpiece and the available clearance on each side of the workpiece. Down milling employs the use of face mill cutters. The surface finish of the face mill cutter is determined by the feed rate and the number of teeth.

- Gang Milling Cutter

It is the kind of cutter that concurrently removes material from the workpiece using peripheral milling cutters of various diameters.

- Staggered Mill Cutter

Staggered mill cutters are produced to a relatively narrow width and are staggered at the perimeter with possible right and left-hand helix angles.

- Concave Milling Cutter

A formed Cutter is a concave cutter. The shape of the workpiece is designed by the form cutter. A concave milling cutter is a sort of Cutter that is formed to meet a convex surface of a circular contour that is half a circle or less in size.

- Cylindrical Milling Cutter

A cylindrical mill cutter is a kind of Cutter that has teeth just on the perimeter surface and has a cylindrical form.

- Hollow Milling Cutter

It looks like a thick-walled pipe. Hollow surface bites are on the interior surfaces. This Cutter is commonly seen in screw machines.

- Woodruff Cutter

This tool is used to carve keyways in wood. The edges are somewhat hollowed out for ease, and the teeth are not side cuts. Straight and staggered teeth are available.

- Thread Mill Cutter

A helical projectile creates the thread. The cutting method allows for the manufacture of threads with a multi-profile ranging from M2 to a nominal diameter of 1 mm.

- Fly Cutter

It is a cutting tool that moves with the rotation of a lathe and operates on the work put into its circular path. A fly cutter is made up of a body that houses one or two tool bits. The tool bits make broader, shallow cuts as the entire device spins. Face mills are useful in a variety of situations, but they are pricey, whereas fly cutters are fairly cheap.

- Use Multiple Flute Tools Where Appropriate

Flutes are helical grooves that wrap around the sides of an end mill and give the tool its name. When chipping lengthy materials like aluminum, tools with a lesser number of flutes (two to three flutes) will provide greater area for the flutes themselves. A greater number of flutes results in a smaller flute space, but it can lead to improved productivity in materials that require shorter chipping, such as iron and steel with a medium to high carbon content. A four flute carbide end mill is recommended for slotting applications while working with steel, stainless steel, high temperature alloys, and iron. This type of end mill may also be an excellent general-purpose tool. Applications that have a shallow radial depth of cut are the best candidates for higher flute counts because they provide more room for chip evacuation. There is a wide variety of design options available for carbide end mills, and the number of flutes can go as high as 12. It is imperative that you make effective use of your multi-flute tools in order to safeguard your financial investment. Multi-flute tools will serve a variety of functions. The following are some of the most frequent:

Three flute styles: These end mills are an excellent example of a tool that strikes a balance between the chip removal volume of a two flute and the strength of end mills with a greater number of flutes. In addition, it has a square end, which allows for the highest possible level of surface quality, much like the two flute option.

Four flute styles: When it comes to milling in materials where chip packing isn’t an issue, four flute end mills are exceptionally adaptable because of their ability to mill through the material. These tools feature a core thickness that is greater than that of comparable tools, which results in enhanced size accuracy and decreased tool deflection. In addition to that, they guarantee a low chip load.

Six flute styles: Because of the longevity of the six flute option, better tool stability is provided, which enables a greater number of cutting blades to remain engaged inside the work material. Consequently, the life of the tool is lengthened, and the cutting edges suffer less chipping therefore.

Variable helix styles: This shape keeps the amount of deflection and vibration to a minimum. Because of these features, the finish is excellent even if the stock removal rates are high.

- Helix angle

High helix carbide end mills are a type of high-performance cutter that is especially developed for use with soft materials. These end mills may also be referred to as high-spiral, shallow wedge, or high helix angle end mills. Helix angles of general-purpose end mills are normally around about 30 degrees. During the milling process, a reduction in the cutting forces, as well as a decrease in the quantity of heat and vibration, can be achieved by increasing the helix angle. Therefore, end mills that have a larger helix angle have the tendency to generate a superior surface finish on the workpiece they are used on.

These cutters have significantly increased feed rates, and there are a multitude of advantages to using them, including the following:

- Deflection of the tool is decreased

- Faster chip removal owing to vertical chip evacuation

- Decreased likelihood of the flute being obstructed

- Increased shearing action results in less need for horsepower, which saves money.

End mills made of high-helix carbide are frequently used with aluminum and other non-ferrous materials. This is mostly because to the positive shearing action that these mills provide as well as the additional cutting edge that protects against wear. Fortuitously, it comes with a trade-off of some kind. The end mill will become less robust and will not be able to withstand heavy depths of cut when fed at high rates. Therefore, angle cutters with a lower helix are more robust, but the surfaces they cut leave a rougher finish.

- Speed

The term “feed rate” refers to the velocity with which we move a cutter across the surface of the material. When milling with carbide end mills, the most crucial step is to ensure that the tool is being operated at the appropriate rpm and feed rate. The rate at which the cutting tool is turned by the router or spindle is referred to as the “speed,” and this rate determines how quickly the cutting tool rotates. The material that is being cut will determine not only the feed rate, but also the spindle speed. Several mills have highly particular operating characteristics in relation to the material families they process. When combined with a low feed rate, a spindle speed that is too high might cause the material to catch fire or even melt.

When combined with a higher feed rate, a spindle speed that is too low might cause the cutting edge of the end mill to become dull, the end mill may deflect, and there is a potential that the end mill will break. You should try to pass the tool through the material as quickly as possible while maintaining the desired level of surface polish. This is a good general rule to follow. The longer the tool turns in any one spot, the more heat that builds up. Heat is your adversary and can burn your material or severely shorten the life of your cutting tool.

When choosing a cutter, a solid method is to try to strike a balance between the feed rate and the spindle speed by working through the workpiece in two separate passes. For the first pass, which is referred to as the roughing pass, you should make use of an end mill that is capable of ejecting a significant quantity of chips at a rapid rate. The second pass, often known as the finishing pass, won’t require as aggressive of a cut as the first pass did and can produce a smoother finish when working at a rapid speed.

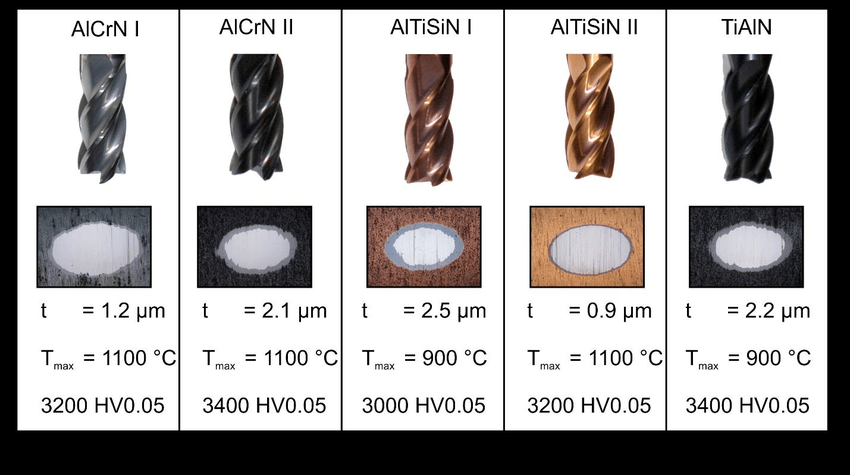

- Choose the Appropriate Coating

The coating is a key procedure that permits the carbide end mill to withstand wear. Although solid carbide end mills outperform and endure longer than high-speed steel in most applications, heat is not carbide’s friend. Over the last decade, advancements in coating technology have resulted in extended tool life and higher productivity. TiN (titanium nitride), TiCN (titanium carbon nitride), and the increasingly common TiAlN (titanium aluminum nitride) or AlTiN (aluminum titanium nitride)—the latter having greater aluminum content—are the three principal types of coatings utilized today. There are more coatings, but they are mainly offshoots of these three. All of these coatings have advantages, but those advantages can only be recognized when working with certain applications and materials.

TiN-coated end mills should be used at speeds and feeds similar to uncoated end mills. The advantage here is significantly improved wear and lubricity. TiCN is an excellent coating when slow feeds and speeds are required due to machine restrictions. It’s frequently the coating of choice for high-speed steel end mills, but in carbide, it may operate at least 80% faster than uncoated solid carbide end mills. The sole disadvantage of TiCN is that it is more prone to failure under intense heat; hence, it is used in slower feed and speed applications.

End mills that have been coated with TiAlN or AlTiN are gaining popularity as a result of their superior performance. They are so effective at transferring heat into the chips that dry machining is often advised. The only exception to this is slotting, which requires the chips to be ejected from the channel, and in this case, heat transfer is necessary. At the cutting edge, where temperatures can reach more than 1800 degrees Fahrenheit, the aluminum in the coating contributes to the formation of a gaseous layer of aluminum oxide. In this way, the carbide substrate is shielded from the potentially destructive effects of heat. Because of this feature, this coating is ideally suited for high-speed and severe milling, particularly when it comes to dry cutting. To avoid edge accumulation when milling non-ferrous materials such as aluminum, brass, plastics, and other non-metallic substances, it is ideal to use an end mill that is not coated and has polished flutes. This is because coated end mills do not allow for an edge that is as sharp as is required for working with these materials.

Working with End Mills: Some Top tips

- The quality of your work will increase, and the amount of hand-finishing that is required will decrease, if you choose the appropriate tools for the material and project you are working on.

- The speed of the end mill must be adjusted so that it is working at its optimum for the feed rate of the material.

- It is possible to increase the life of your end mill by reducing the working speed by just fifty percent.

- Choose the appropriate number of flutes for the task at hand; accurate chip evacuation is essential, since hot cutters can result in poor-quality cutting (burnt material, burred edging and dull tooling).

- When working with tougher materials or situations requiring a high level of productivity, carbide end mills are the tool of choice.

- It is sometimes required to utilise additional length end mills, however in order to prevent deflection, which is the bending of the bit, it is important to work at the appropriate speed and feed rates and always use the end mill that is the most rigid (shortest and broadest) available for the application.

- To stop the accumulation of chips, you can use coolant or compressed air.

- Instead of only using a tiny section of the cutting edge near the tip, use the entire side of the cutting edge. As a result of the heat and effort being dispersed over a greater surface area, the endmill’s shelf life will be improved as a result of this.

For the Best Carbide Milling Cutters, Please Contact HUANA!

The greatest carbide milling cutters are available from HUANA, which is the leading provider in the industry. It does its business in Germany and Switzerland, where it obtains cutting-edge five-axis CNC grinding equipment and raw materials of the highest quality. Only items that pass all of the checks required before leaving the manufacturer can be exported. You can rely on them as the most trustworthy suppliers of carbide milling cutters. Get in touch with HUANA if you are looking for the best carbide milling cutters

Conclusion

The information that was provided for you in the previous paragraphs should prove useful as you search for an appropriate carbide end mill. Please do not hesitate to get in touch with HUANA for further conversation. It is possible for the tool to cut into the material of the work piece with a minimum of vibration and tensile stress if the appropriate milling cutter angle, size, and feed method are chosen. Additionally, if the manufacturer is aware of the conditions under which milling holes is more effective than drilling, they will be able to process work piece blanks into exquisite parts in a highly efficient and cost-effective manner. Get in touch with HUANA if you are interested in purchasing carbide milling cutters.