Buying your first router bits is a good idea. Wood shops contain at least one router that can be used for a variety of tasks. However, without a router bit, you cannot do much of the work. Since there are so many options, it can be extremely confusing if you are new to routing. The following is a guide to help you pick the best router bit set for your project.

What Is A Router Bit?

They are attachments that attach to a router tool and are mainly used for cutting and carving wood. A few basic router bits are essential for anybody who uses routing tools. Router bits are distinguished from their counterparts by having fast-cutting edges made of high-speed steel or carbide. Cutting edges on carbide tips will remain sharper for a longer period than those on steel tips. A spinning ball-bearing pilot may also be found on the tip of some edges-cutting router bits if they have such features. A rotating ball-bearing pilot allows for control of how wide the cut is.

Router Bits Type

By itself, the router is ineffective, but when paired with the right bit, it will create a masterpiece! To that end, here’s a quick rundown of the most popular types of CNC router bits.

Straight Cut Router Bits

Probably the most common router bit design is the straight cutting bit. With a flat base, this machine cuts horizontally in keeping with its name. The straight cut bit can also be used for very useful plunge cuts. By lowering the bit to the surface, cutting into the surface can be begun.

Cuts with a plunge saw can be used to make mortise joints, recesses for hinges, striker plates and latches and bolts for locks. A drawback of straight cut bits is that they are usually unguided, so you need to either use a piece of guide or have a very steady hand to ensure a straight cut!

Flush Trimming Router Bits

The flush trimming bit is specifically designed for trimming edges that hang over adjacent surfaces so that they are flush with the surrounding areas. Laminate and wood veneers are great examples of this. In most cases, when a laminate or veneer is applied to a surface, the edges will overhang, especially if the material covers over and around the shape of an object.

Most cutting bits are guided to ensure they remain flush with the surface they are cutting back to. It will therefore feature a bearing that has the same diameter as the cutting bit either at the top or the bottom.

To avoid trimming back farther than the bearing surface, cut only on the bearing surface.

Carbide tipped router bit

There is one more main element of a router bit that you may have noticed. This is the bearing guide, which can be seen at the base or tip of the bit, or the top of it has a top bearing guide.

Its purpose is to assist you in maintaining accuracy when you are (usually) shaping or detailing a piece of work with your router bit.

Bearings are very smooth in rotation, so they prevent juddering and jumping around, which enables your router bit to make straight and accurate cuts on any surface you work on.

As a rule of thumb, router bits with bearings usually come with bearings of various sizes as part of the set or included in the bit. Due to the bearing following the object you are cutting, the bearing size determines how deep the cut will be, so to change the depth of the cut you simply change the bearing for another size.

Rabbeting Router Bits

Rabbet router bits are used to cut rabbets. They are referred to as rabbet joints or shoulders.

It is most often used for the jointing of drawers and cabinet frameworks, specifically for rabbets or shoulders.

A rabbit bit typically comes with a variety of bearing sizes so you can cut joints at different depths, depending on the size of the bearings attached at the base of the bit.

Specialty Bits

include router bits that are designed for specific tasks. Many times, the bits are too large for handheld use and must be used safely on a router table. While they can be used in handheld routers in some cases, they are mostly not suitable for handheld use.

Core Cutting Box Bit

The core cutting bit of the image below has a concave bottom, which will allow it to cut channels and shapes.

The machine is not only used for cutting channels but can also create decorative effects in wood objects such as doors or table edges.

It can also be used to hollow out objects with great effectiveness since it is also non-guided, i.e. it does not have a bearing.

V-Groove Cutting Router Bit

By comparison, a V-bit produces a pointed, V-shaped channel instead of a round one as a core cutting bit does.

Decorative grooves and various aspects of cabinetry, including tabletops and chair legs, are typically made using wire cutting similar to how the wire is cut.

A variety of channels can be created with a V-bit, including shallow channels with thin walls and deep channels with thick walls in addition to the standard shapes and angles found on most decorative bits.

Rounding-Over Router Bit

Rounding over router bits uses the same methods as edge chamfer router bits, such as removing sharp or acute edges and smoothing them.

In the same way as chamfer bits, this type of bit is commonly used for smoothing out the edges of shelves, tabletops, cabinets, and chairs as well as anywhere else where smoothness is required.

Additionally, just as with all other bits for making very precise cuts, the bearing guide controls the depth of the cut as well as guides the rounding bit. Due to this reason, rounding bits are typically supplied with a variety of bearing sizes that can be changed based on the cutting depth required.

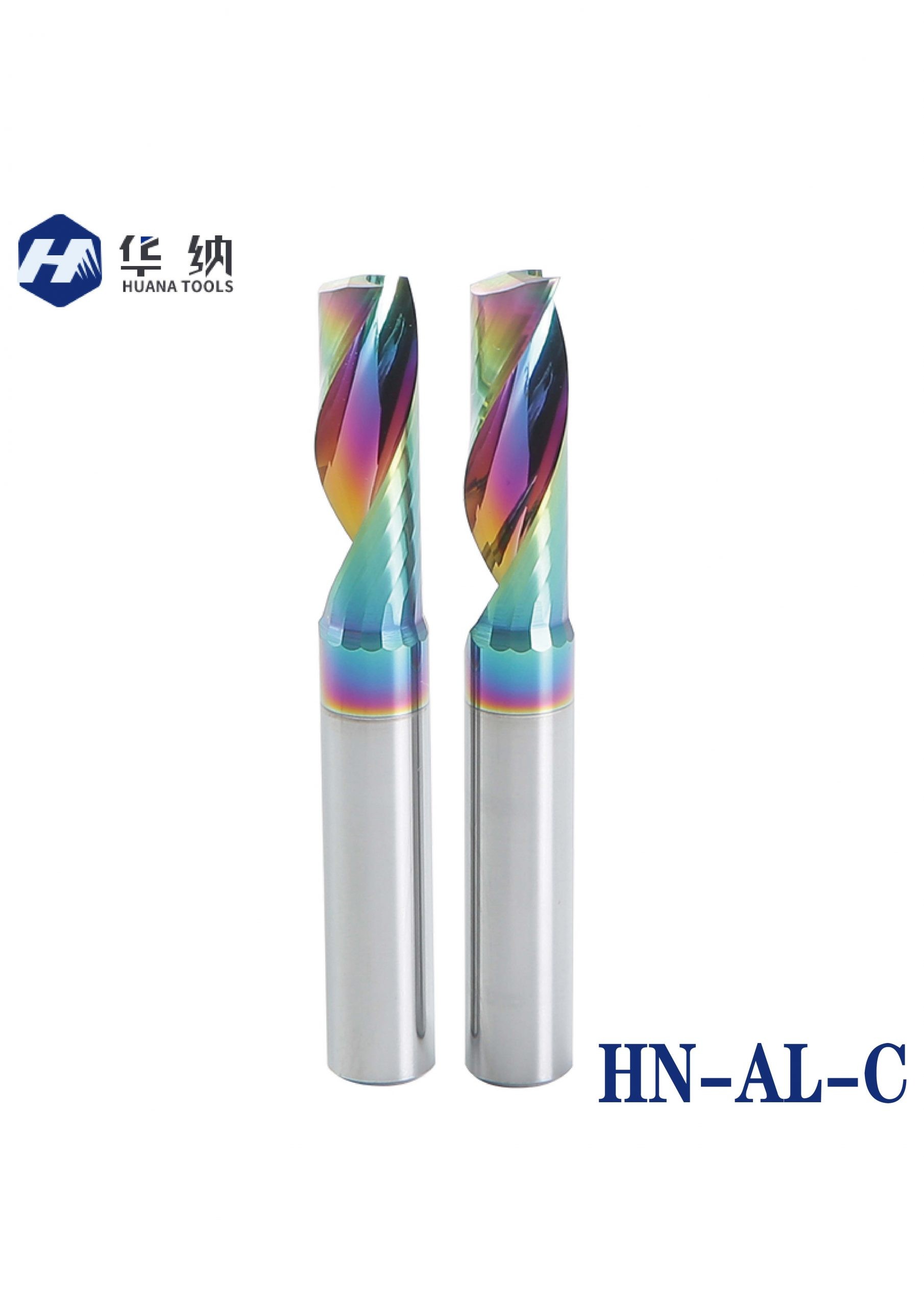

Single Flute Aluminium End Mill

A single flute aluminium end mill is just better for some materials. A softer material will be easily scratched by a single flute aluminium end mill. In my opinion, it’s a good idea to make it easier for chips to get out of the way to prevent them from poking back in and scratching things up. Some plastics will polish with a two fluted polisher, although many plastics will not polish well with a two fluted polisher. Several wood products will benefit from a single flute end mill cutter. This could be true in terms of softwoods as well as MDF. It is sometimes beneficial as well to use a single flute cutter for cutting any stack of sheets of paper. As you may expect, these differences are not usually very profound, and usually appear at high RPMs when there is a greater power demand.

Working in different materials

Wood

Routing should be done with the grain of the material. In this way, you will provide a perfect surface and minimize tear out by ensuring a flawless surface. The best way to prepare hardwoods for routing is by applying a thin coat of water to the end grain and letting it set for a few minutes before you continue. As a preventative measure, it is recommended that the wood is softened before it is cut, which will help to avoid problems down the line.

The slower the cutting speed, the easier it will be to avoid problems. Nevertheless, it is worth mentioning that the term soft or hardwood usually refers to the type of tree the wood is made of, as opposed to specifically its hardness, and both types can be hard or soft depending on how they are produced. Some hardwoods have a softer decay resistance than softwoods, but the hardest hardwoods have a decay resistance that is substantially higher than softwoods.

Ensure the wood does not have any knots before routing. If you have to approach knots that are smaller and tighter, you should brace yourself and slow down your rate of feeding. Larger, looser knots could cause problems and you should plan your project accordingly.

Some of the most frequently used CNC router bits for wood are 1/4″ Shank Engraving Bits, SpeTool CNC Router Bit Kit and many more.

Aluminium

Various specialized cutters are used in CNC routers when cutting aluminium, but many of these cutters will not be appropriate for such a task. Therefore, it becomes vital to have a special cutting tool that is specific to aluminium. In most cases, the manufacturers prefer to use carbide endmills with 2 or 3 flutes to obtain the desired results. It is very useful to have these cutters to increase the rpm in order to ensure that the blades will be able to work correctly at high rates. To determine this, we have to look at the surface speed, and the carbide mills have far greater surface speeds than any other cutter on the market today. Considering that aluminium should not be cut with compression cutters or high-speed steel cutters, it is imperative to avoid their use. These machines will cause damage to the metal and will have an adverse impact on the operator’s ability to do their job.

Plastic

Hard and soft plastics can be categorized broadly into two categories: rigid and flexible. Acryl, nylon, polyvinyl chloride (uPVC), hard PVC, and laminate are hard plastics. Getting a clean slice through these materials can be difficult if the material splinters. It’s better to be careful and remove a few large chips than leave large chips on the surface. When using soft plastics, the waste material often comes off in the form of curls rather than chips, ensuring that the cut is cleaner. If you are going to be working with any type of plastic, you should use a cutter made of solid tungsten carbide instead of an HSS cutter, since an HSS cutter will quickly become blunt.

Dust collection is crucial for a wide variety of applications, but it is particularly important for routing plastic. Electricity charges the shavings that are emitted by the router bit, allowing them to stick to everything and become electrically charged. Dust and debris from these sources are difficult to remove or sweep up, so removing dust and debris as you work with a dust extractor will reduce build-up.

Router cutter material

Tungsten Carbide Tipped (TCT)

Cutting edges are two tungsten cutting edges attached to a steel blank and brazed together. Such cutting edges are ideal for use with all wood-based products and man-made boards. Compared to HSS cutters, TCT cutters will last much longer, however, after using them you will need to sharpen them with a diamond or ceramic stone since they do not need to be sharpened as frequently as HSS cutters.

High-Speed Steel (HSS)

High-speed steel knives, made of high-grade steel, are ideal for cutting and finishing softwood (i.e. not hardwoods or man-made wood products). However, when heavily used, they are at risk of damage due to their high thermal conductivity. When they have sharpened again, they need to be honed on a wet stone. However, if the cutter is shaped, this can be a very delicate job, as it can affect its balance.

Solid Tungsten Carbide (STC)

STC cutters tend to have small diameters meaning that brazing them onto carbide cutting tips would prove very difficult. Given that they have the same cutting edges as TCT routers, the comments made above need to be applied in the same way as they do for STC routers.

Replaceable blade cutters

These cutters have steel bodies mounted with replaceable tungsten cutting edges that are all screwed into place (normally). These cutters are commonly used for large diameters since replacing the cutting edges on small diameter cutters can often be quite expensive.

Tips to use Router Bits

In most cases, it is best not to attempt to cut a complete pattern in one pass; if you do so, the finish will be poor. When the profile is formed by taking several passes and removing a little stock each time, the resultant finish will be much smoother and professionally done than if the profile had been formed in a single pass.

- You should either use a bearing guided bit or a router fence when you are making freehand straight cuts to ensure that your cuts are perfectly straight.

- It is important to remember that featherboards will help keep the piece of work flat on the table, flat on the fence, and more importantly, prevent the piece from flying backwards due to kickbacks.

Bottom Line

There are some things to consider before purchasing the best router bits, but selecting the right one isn’t that difficult. Generally, you will need lots of help if you are a beginner before purchasing rail and stile router bits. When purchasing router bits, the most important things to consider are their general shape, size, and purpose.

The collection of router bits will grow over time as a result of regular work. Investing in a smaller set of inexpensive bits may be less risky than purchasing a large set of high-end bits you may not use or need, no matter how sure you are that you need them.