Description

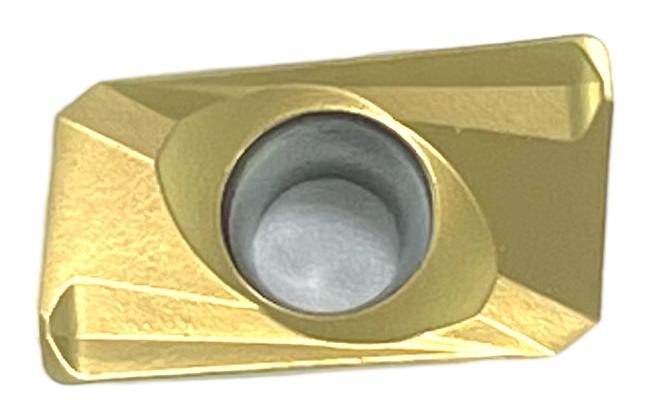

The carbide inserts that go into milling machines are removable tips and, therefore, don’t form part of the machine itself. In addition, they can be interchangeable, which means they can be substituted and traded once they are used. Milling inserts are commonly used when milling cutters are used to cut or shape metals like steel, aluminium, and cast iron. Their purpose is to protect your milling cutter from extreme heat. A multipurpose bevelling machine like the EKF can bevel steel, stainless steel, non-ferrous metals, brass, plastics, and others at 30 or 45 degrees. Also, it is capable of deburring and chamfering, straightening edges, applying internal and external radii, and countersinking holes from a diameter of 7/8″. There is no doubt that solid carbide tools have the advantage of extended tool life and quicker cutting speeds than other substrates. However, reliable carbide tools are more brittle, can wear out quickly, and must be used with rigid tool holding systems. Solid carbide tools have good strength, resilience, and versatility for roughing and medium roughing of steel, alloy steel, and cast iron, mainly for quick cutting at high speeds. An exceptional grade and titanium coating are available. After this, a particular treatment is performed on the layer to reduce the level of roughness. The insert is secured onto a specially made steel blade which is double-ended. The primary grade for cast iron. The secondary grade for steel. CVD-coated milling grade for high-speed machining of cast iron and steel. It is characterized by a high degree of toughness and heat conductivity, while the treatment applied to the surface provides the ideal degree of resistance to chipping and cracking. The properties of this grade are the most suitable for cutting steels or machining with low cutting loads to guarantee long tool life and accurate machining, especially in the machining of heat-resistant superalloys.