Description

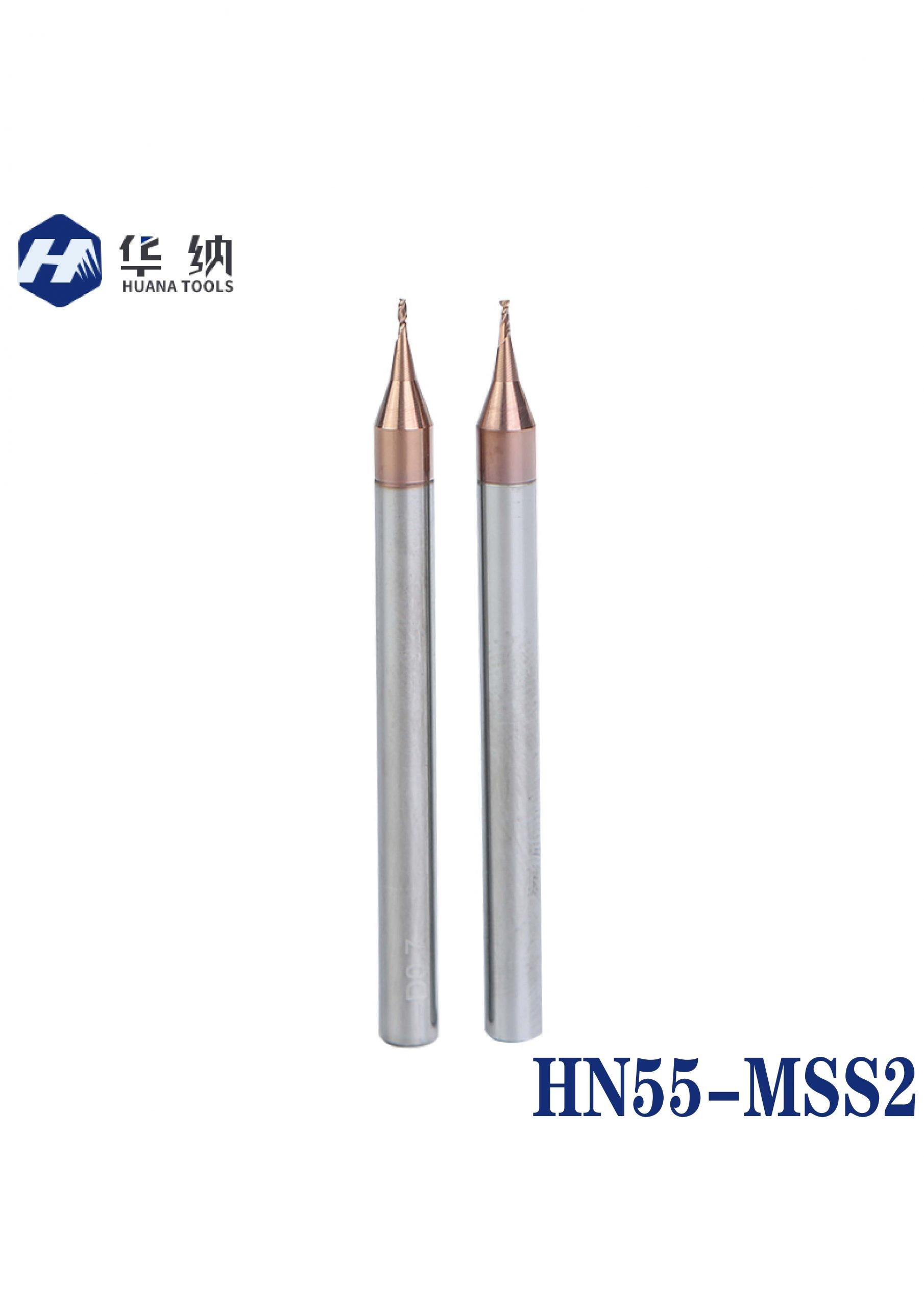

| Order Number | HRC | Flute | Material | Coating | Helix angle |

Work Material | |||||||

| Carbon steel Cast iron |

Alloy steel | Hardnened steel |

Stainless steel |

Copper Alloys |

Aluminum Alloys |

||||||||

| <35HRC | 35-48HRC | 46-55HRC | 55-60HRC | ||||||||||

| HN55-MSA2 | 55 | 2 | Carbide WF25 | Uncoated | 35 | ○ | ● | ||||||

| HN55-MSS2 | 55 | 2 | Carbide WF25 | TISIN | 35 | ● | ● | ○ | ○ | ||||

| HN55-MBA2 | 55 | 2 | Carbide WF25 | Uncoated | 30 | ○ | ● | ||||||

| HN55-MBS2 | 55 | 2 | Carbide WF25 | TISIN | 30 | ● | ● | ○ | ○ | ||||

| ● Most Suitable ○ Suitable | |||||||||||||

This is an excellent mini end mill bit! These micro or miniature cutting tools feature a smaller cutting diameter, explicitly designed for hardened tool, die, stainless, and mould steels. The shank diameter varies from .005″ to .120″. For maximum strength, the corner radius profile for the Hardened Steel End Mills is reinforced. It is possible to perform various tasks using these high-performance carbide end mills, ranging from soft to hard materials, with a 30° helix and a conventional gear geometry, which applies to various materials. The precision and performance of our products are guaranteed by the close tolerances they are manufactured. Each tool improves surface finishes with a distinct mirror-like finish on the cutting edge or tips while removing the maximum amount of material. As a result of the micro end mill coatings, machinists’ most common difficulties and mishaps are eliminated. In addition to aiding chip evacuation

when machining gummy/sticky materials, the abrasive paper also adds strength And durability to the tool to make it strong enough to handle aggressive machining operations in materials that are impossible to machine. To successfully implement your turning, milling, or other applications, selecting the appropriate coating solution is essential. An end mill coated with titanium aluminium boron nitride is more resistant to heat and wear at high cutting speeds than titanium aluminium nitride or titanium nitride because it lubricates the end mill for stability in high temperatures and superior wear

resistance. It is possible to run carbide at higher speeds than high-speed steel or cobalt steel, and it resists wear and high temperatures in the cutting process.