Description

| Order Number | HRC | Flute | Material | Coating | Helix angle |

Work Material | |||||||

| Carbon steel Cast iron |

Alloy steel | Hardnened steel |

Stainless steel |

Heat Resistant Super Alloys |

Titanium Alloys |

||||||||

| <35HRC | 35-48HRC | 46-55HRC | 55-60HRC | ||||||||||

| HN55-LNS2 | 55 | 2 | Carbide WF25 | TiSIN | 35 | ● | ● | ○ | ○ | ||||

| HN55-LNS4 | 55 | 4 | Carbide WF25 | TiSIN | 35 | ● | ● | ○ | ○ | ||||

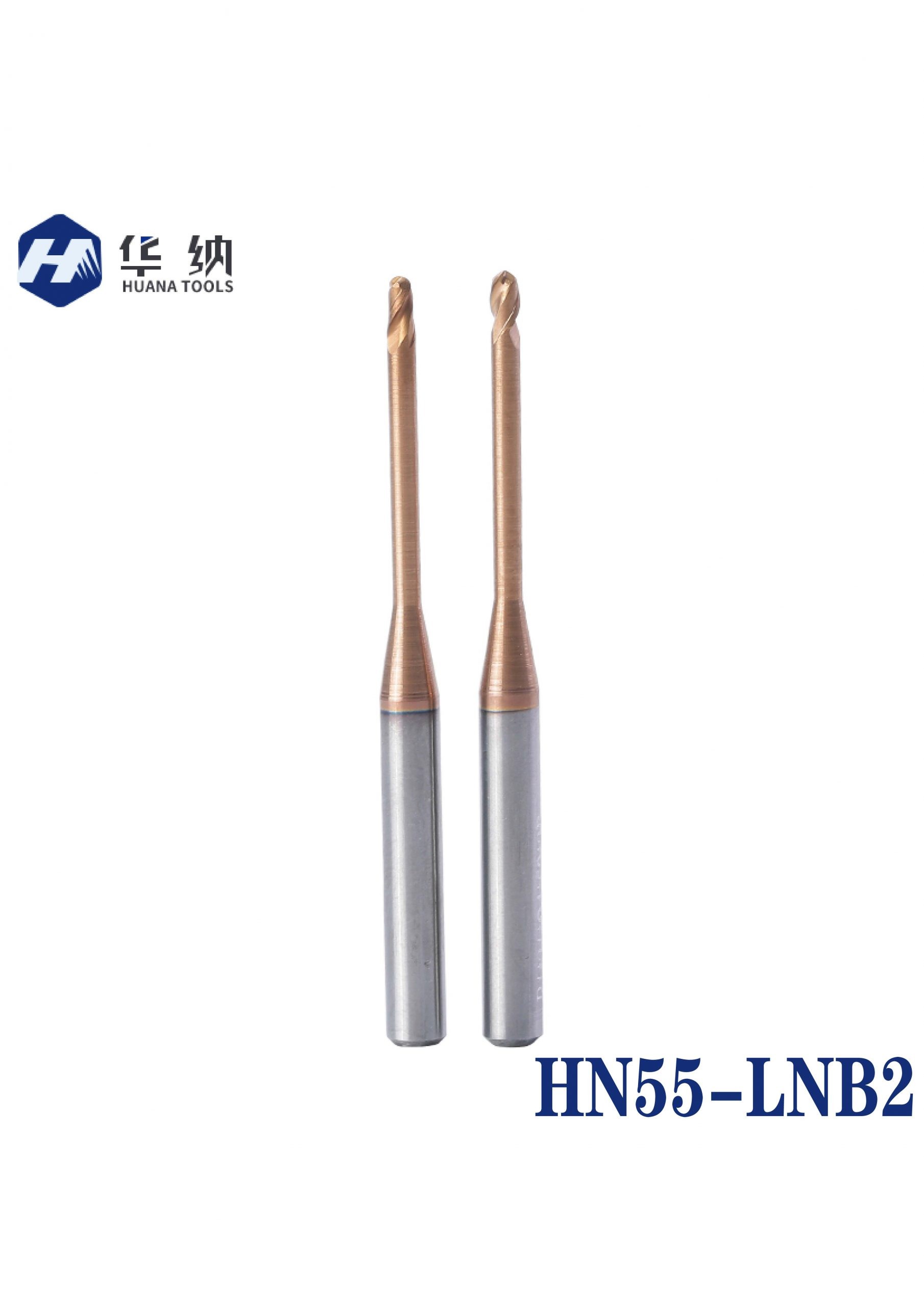

| HN55-LNB2 | 55 | 2 | Carbide WF25 | TiSIN | 30 | ● | ● | ○ | ○ | ||||

| HN55-LNC4 | 55 | 4 | Carbide WF25 | TiSIN | 35 | ● | ● | ○ | ○ | ||||

| ● Most Suitable ○ Suitable | |||||||||||||

Copper electrodes can be machined with high accuracy and minimal burrs using the long neck end mill series. An angle of the helix that is high can ensure improved shearing performance. This tool’s high bending and abrasion resistance make it suitable for high hardness, high-speed cutting, bending resistance, and abrasion resistance, exclusive use for high hardness and high-speed cutting applications. It is essential to understand that you can use that end mill bits for side, end, finish, etc. Suitable for steels, including carbon steel, soft alloy steel, die-steel, tool steel, cast iron, titanium, aluminium, and more. A u-shaped groove is incorporated in the bottom of the end mill bits, reducing cutting resistance effectively, making the bit sharp, durable and convenient to remove chips, further improving machine efficiency. The edge of end mill bits is hard and sharp with TIAIN coating, which is very efficient for heat processing of materials, allowing it to be processed as quickly as possible, reducing change over time and improving production efficiency. By lowering the cutting resistance of the blade to a large extent, the large front angle makes it easier to remove chips while cutting, significantly increasing the efficiency of the machine. There are two flutes in the carbide end mill design, which enables it to be applied to all types of metals other than ferrous, such as aluminium, iron, and plastics. It has a broader spiral chip space; hence, it does not stick and can remove chips more quickly.

A very efficient hand tool for cutting steels, stainless steel, cast iron & hardened steels by dry or wet cutting. The flat-top design makes cutting various materials easy, including stainless steel. It contains cutting edge details that are sharp, has accurate positioning, a smoother blade, and reduces the need for knives. There are many applications for this product. You can use it for appliances like phones, tablets and calculators, and light commercial machinery, like heavy equipment.