Description

| Order Number | HRC | Flute | Material | Coating | Helix angle |

Work Material | ||||||

| Carbon steel Cast iron |

Alloy steel | Hardnened steel |

Copper Alloys |

Aluminum Alloys |

Titanium Alloys |

|||||||

| <35HRC | 35-48HRC | 46-55HRC | 55-60HRC | |||||||||

| HN55-A3 | 55 | 3 | Carbide WF25 | Uncoated | 35 | ○ | ● | |||||

| HN55-A3-C | 55 | 3 | Carbide WF25 | DLC | 35 | ○ | ● | |||||

| HN55-UA3 | 55 | 3 | Carbide WF25 | Uncoated | 40 | ○ | ● | |||||

| HN55-UA3-C | 55 | 3 | Carbide WF25 | DLC | 40 | ○ | ● | |||||

| HN55-BA2 | 55 | 2 | Carbide WF25 | Uncoated | 30 | ○ | ● | |||||

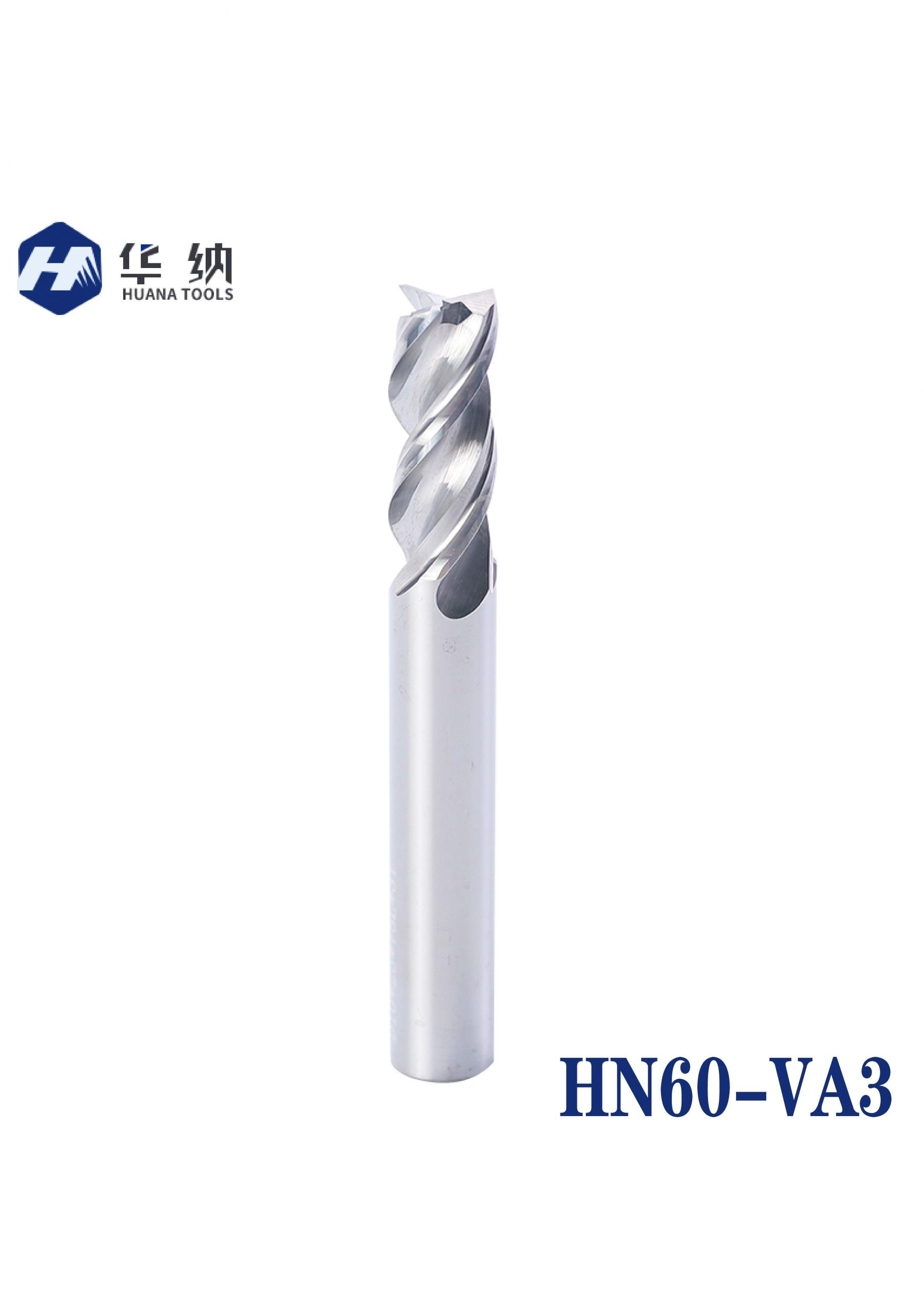

| HN60-VA3 | 55 | 3 | Carbide WF25 | Uncoated | 42 / 45 | ○ | ● | |||||

| HN60-VA3-C | 55 | 3 | Carbide WF25 | DLC | 42 / 45 | ○ | ● | |||||

| ● Most Suitable ○ Suitable | ||||||||||||

When cutting aluminium into suitable shapes and providing an excellent finish, you need specific tools. Aluminium cutters are critical to this process. Due to its abrasion resistance and lightweight, aluminium is suitable. Aluminium is used in almost every industry. By incorporating specialized cutter geometry and smooth coating finishes with rigid surfaces, carbide end mills are especially suited for cutting aluminium aggressively. The aluminium milling process can be complicated since the chips can jam in the flutes, and the material can stick. Modern aluminium carbide end mill bits have large flutes for the best metal removal rates. The Ultra-Tech carbide end mills have been specially designed for milling aluminium alloys and other aluminium-containing materials. It is possible to get these tools in two and three flute designs, solid and coolant fed, to serve slotting and roughing applications.

Also, there is a preference for a high helix angle, typically 45 degrees at the base. As a result, chips are moved up and out of the cutting zone, providing a superior finish. A two- or three-flute mill will work best if you’re milling aluminium since it allows you to have smaller flute areas. It becomes harder to evacuate chips effectively with higher flute counts when running in aluminium at high speeds. Aluminium alloys leave a large chip, and as an end mill has more flutes, the chip valleys become smaller. You will save a significant amount of time by choosing and applying the suitable carbide end mill. By having flute geometry, the milling grooves are much smoother and have better surface finishes. In various popular tip widths, these mills are available in 11/64″ x 6-1/2″ and 1/4″ x 6-1/2″.