Description

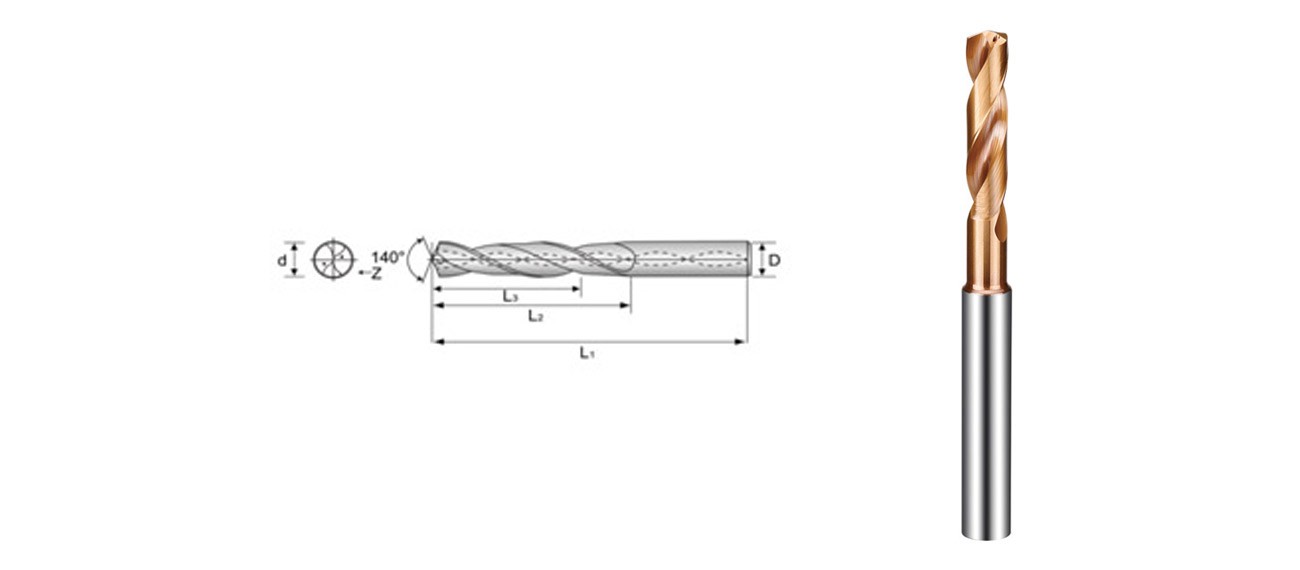

There are drill bits made of solid carbide with small holes that allow coolant to pass from the drilling machine to their tips so that coolant can be pumped down the drilling machine. With the use of a coolant, you can lubricate and cool down the drill bit in such a way as to increase precision when drilling and prevent damage to the cutting edge as well. Carbide drill bits are not only hard, wear-resistant, and heat resistant, but they are also corrosion-resistant. Compared with high-speed steel, cobalt, or powdered metal drill bits, they are more difficult to work with and require a rigid setup such as a fixed-spindle machine. With the bits, holes are created with a smooth finish and usually do not need to be reamed after drilling as they make a very precise hole with a smooth surface. It is also important to note that carbide drill tips with coolant hole bits provide a good combination of strength and accuracy when drilling into various materials. A carbide drill tip with a coolant hole bit is the best choice for drilling operations. The design of this tool is based on the experience we have acquired while designing drills over the years. Therefore, we have developed our tungsten carbide drill with a built-in cooling system. In addition to installing an internal cooling system to remove chips from the work area, this feature extends the time between maintenance. Consequently, tungsten carbide drills gain a significant advantage over HSS drills from the point of view of their cost-effectiveness.