Description

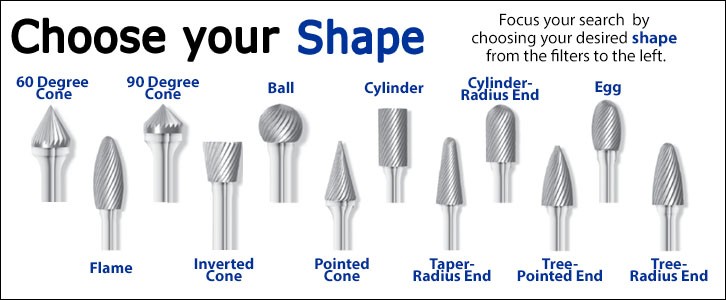

All the properties desired by demanding users can be found in carbide burrs. These burrs, with their various shapes and sizes, can be used to process different materials and workpieces. With carbide burrs consistently high quality, the end-users can count on a comprehensive range of products guaranteed to provide the right solution for any demanding task. Aside from the products’ exceptional cutting performance and aggressiveness, the products offer improved chip removal and reduced thermal load. Among the many uses of carbide burrs, everyday work is excellent.

Additionally, these burrs offer an excellent finish and a standard cut. When it comes to cutting soft, long-chip materials, aluminum is a great option. Plastics and aluminum are also included in these materials. Generally, the removal rate of plastics and aluminum is high, and the loading load is reduced.

Aside from its general suitability, the double-cut also produces tiny chips and is more convenient to handle. Further, the tool is very comfortable because of its low vibration.

Its toothing was optimized for steel processing and is a high-performance cut. Carbide burrs perform substantially better than standard cuts at removing stock. In addition to stainless steel with a high corrosion and acid resistance, the high-performing cut is ideally suited for the challenges of austenitic steel. This cut, too, removes a much greater volume of stock than a standard cut. Optimized burr geometry is responsible for this. Heat tinting is minimal as well as a benefit.