Aluminum alloy doors and windows may be sized and shaped according to your preferences, have an appealing appearance, and can be purchased in a wide variety of surface coatings, color options, and hardware finishes. They are an economical option, which makes them a favorite among contemporary architects. When combined with the appropriate glass, they may also be energy-efficient, ensuring that heat is retained during the winter and dissipated during the summer. One Flute Spiral Bits for Aluminum Alloy Doors and Windows are available at Huana.

Either the realization that the overall vision of the finished design was damaged because of the quality of the materials used or the installation of those materials is one of the most frustrating things that can happen to an architect right at the very end of a project. This article offers a complete look at everything having to do with aluminum alloy doors and windows so that you can make the best option for your customers as well as for your reputation as the project manager or architect.

The Process of Manufacturing Aluminum Alloy Doors and Windows

The term “aluminum door and window” refers to the frame, wooden stick, and fan of doors and windows that are composed of aluminum alloy. Aluminum door and window is the shorter name for aluminum alloy door and window.

The components and materials used in windows should adhere to any applicable national standards, industry standards, or local requirements that may be in place. That is to imply that we have to exercise stringent control over the deviation of the material thickness in order to guarantee that the wall thickness is conformed to the design size as well as the obligatory specifications of the national standard.

In order to prevent corrosion with the aluminum material, the material and accessories that we need to choose, in addition to stainless steel, should be treated with an anti-corrosion treatment. The doors and windows made of aluminum alloy should be fabricated in the workshop from start to finish, and the technique that should be followed is as follows:

Profile blanking, punching milling, profile assembly, assembly layering, assembly casing, semi-finished product protection, and storage are some of the processes that are included in this step.

The necessary operators will get the profile banking sheet and working diagram that was produced by the design department via the Manufacturing Department’s efforts.

- Blanking process needs and critical operational points:

Examine the surface of the profile to ensure that it is bright and clean and that there are no noticeable scratches, bruises, or deformations. In addition, inspect the profile to see whether the colour is consistent throughout, whether or not it has an integrated protective coating, and whether or not it contains any foreign bodies.

We ask that you proceed with the blanking in accordance with the processing figure in the same size and quantity. The tolerance for the length of the profile cutting is +/- 0.5 mm, the angle tolerance is +/- 0.5 degrees, and the verticality variation is 0.5 degrees. It is imperative that you pay close attention to ensure that there is not an evident burr. It is important to avoid cutting the profile while you are cutting, handling, and storing the material. After the first piece has been thoroughly examined and quarantined, production may begin, but only after the dimensions have been double-checked to ensure that they are accurate.

- Assembly procedure and critical operational points:

Before assembly, verify the profile surface and size. Examine the surface to ensure that it is clean, smooth, and free of any scratches. When it comes to the surface of the assembly, there should be no pollution and no oil contamination, and the assembly should be completed as quickly as possible within two days after the blanking process. Verify that the amount as well as the dimensions of the material are correct in accordance with the assembly design. Please let us know as soon as possible if there is a problem. It is a serious violation of the law to blank out the improper components. After the assembly is complete, the surface of the profile should be uniform and smooth, and the height difference between neighboring components should be no more than 0.5 millimeters.

The variance in the dimensions of the assembly is +/- 2.0 mm, and the discrepancy in the diagonal dimensions is +/- 3.0 mm.

- Storage

When being stored, products need to be put in an area that is both smooth and clean. The temperature of the product storage area should be lower than 50 degrees Celsius, and the distance from any sources of heat should be increased by one meter. Doors and windows at the location of the installation should not remain there for more than two months. Doors and windows should not be installed in a greenhouse until the temperature rises above 0 degrees Celsius; during this time, they should be stored within the greenhouse for 24 hours….

Incredible Features of Aluminum Doors

Wooden doors are still the standard in most older houses, but they are readily plagued with termites and may deteriorate. Additionally, they provide very little insulation and are simple to breach. Aluminum, on the other hand, is only second to iron in terms of worldwide utilization due to its strength and durability.

Your house may be dramatically improved, both visually and practically, by installing an aluminum door. An aluminum door might be a smart option if you want to offer your house a modern aesthetic with current features. See why, will we?

- Weather Resistance

Aluminum is resistant to practically all weather conditions thanks to various surface treatments. This is crucial since a weak door can rust on the exterior, giving your house a drab appearance. Aluminum is superior than lumber in areas subject to severe winds since it is a material with greater structural stability.

An aluminum door, unlike those made of other materials, won’t bulge, split, or break throughout the course of its lifespan. The most adaptable metal, it prevents heat from escaping your house during the winter and prevents heat from entering during the summer by acting as insulation against both the cold and heat.

When it comes to climatic endurance, iron lags behind aluminum as well since it expands in excessively high temperatures, making iron doors difficult to open. This problem does not exist with aluminum doors.

- Cost-Effectiveness

Aluminum is still less expensive than wood and other materials to make doors, despite being better to them. Aluminum is widely accessible on earth, as opposed to wood, which originates from rapidly decreasing forests; as a result, its price has remained relatively cheap. With its presence in more than 270 minerals, it is the metal that is most easily accessible worldwide.

Aluminium doors are essentially maintenance-free and may survive for decades at a time since they are very strong and resistant to corrosion and other deformations. They essentially pay for themselves as a result. On the other hand, if a wood door is not consistently maintained, its lifespan may be significantly shortened.

- Uniqueness

In addition to its usefulness, an aluminum door is stylish and offers additional design options. It’s not necessary to repaint aluminum doors since they typically have a powder-coating finish. There is a large selection of colors for these powders. This is advantageous since you can almost always find a door that complements the décor you want for your house.

Aluminum can be made into bigger doors without the risk of warping since it has a robust structural design, unlike lumber. The most adaptable material for doors overall, both in terms of topology and size, is aluminum.

- Sustainability

It is imperative that we all play a role in preserving the earth since rising global temperatures pose a serious danger to irreparable environmental harm. You may avoid utilizing components derived from widespread deforestation by selecting an aluminum door over a wooden one.

Additionally, the carbon impact of aluminum doors is relatively small. Aside from that, aluminum is entirely recyclable. It can be recycled a limitless number of times with only 5% of the original energy input. Any outdated aluminum door frame that you no longer need for your house might be changed into something completely new.

- Capability to Decrease Noise

Given the growth in traffic, loudspeakers, and other noise sources in metropolitan areas, it is likely that you sometimes experience noise pollution that is virtually intolerable. In addition to providing insulation against heat, aluminum doors also do so for sound.

But it also relies on the kind of glass and sealant that are utilized in your door. A very high degree of sound insulation may be achieved in aluminum doors by using triple-glazed glass and high-elasticity sealants.

In essence, aluminum doors are excellent for the environment and your house. You do not have to worry about replacing or constantly mending them, which is simple on your money and gives you piece of mind. They enhance your areas visually, which is the icing on the cake.

AIS Windows is your finest option whether you are searching for a straightforward aluminum door or a sophisticated one with elaborate glass patterns. We provide high-quality aluminum windows and doors that are durable and seldom prone to discoloration. We have been providing satisfied consumers with local and international services since 1984. Our aluminum windows and doors provide protection, privacy, and energy efficiency. We offer just the perfect product for your areas, no matter what you are searching for in a door.

Tips How to Correctly Cut Aluminum

- Determine Your Feed and Speed Rates

Routing aluminum requires more patience than routing wood because of the material’s unique characteristics. Because of this, you need to be sure that you calculate both your feed and speed rates. Utilizing an online feed rate calculator is the method that is recommended for getting this done.

- Make use of Carbide Bits

Carbide-coated cutters can withstand the high RPMs required for aluminum routing. Even high-speed steel and cobalt will be insufficient. Remember to tell your feed and speed calculator that your bit is carbide-coated; this will result in higher RPMs.

- Make Use of a Misting System

A Mister system will assist cool down the bit as it cuts through the metal, increasing the bit’s shelf life and contributing to the material’s ability to maintain its integrity.

- Recurring Shallow Passes

Make the error of attempting to save time by making deep cuts. It is incompatible with aluminum. Make many shallow passes to achieve your desired depth; this will provide you better access and make it easier to remove your chips.

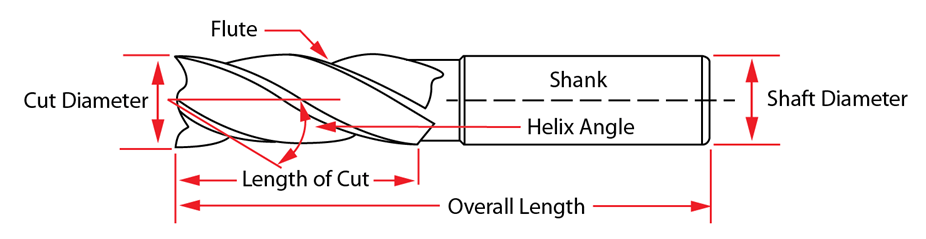

- Take Care of Your Flutes

When working with wood, you might be accustomed to using a cutter with four flutes; nevertheless, when cutting aluminum, you should only use a cutter with a maximum of three flutes. This prevents extremely big chips from causing your router to jam. Keep in mind that having fewer flutes will demand a slower feed rate, which is something that your CNC router will be able to manage more easily.

Contact Huana to Order One Flute Bits For Aluminum Alloy Doors And Windows

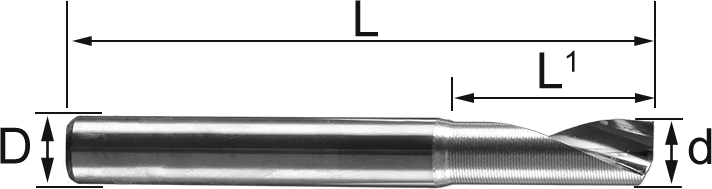

At Huana, one-flute bits of varying size and shape are available for use in a variety of applications. These bits are designed for use with aluminum alloy doors and windows. High quality at a reasonable price Huana one flute bits for aluminum alloy doors and windows come in full size. One Flute Bits for aluminum alloy doors and windows are constructed out of high performance carbide material, which has strong wear-resistance, high hardness, and high toughness. These characteristics make the material ideal for this application. Make sure to get in touch with Huana if you have any more questions about one-flute bits for aluminum alloy doors and windows! Please contact us if you have any queries regarding any of our quality tools. If you have any specific, requirements for your purchase, such as drop-shipping guidance or gift orders, please contact us; we are always delighted to assist.