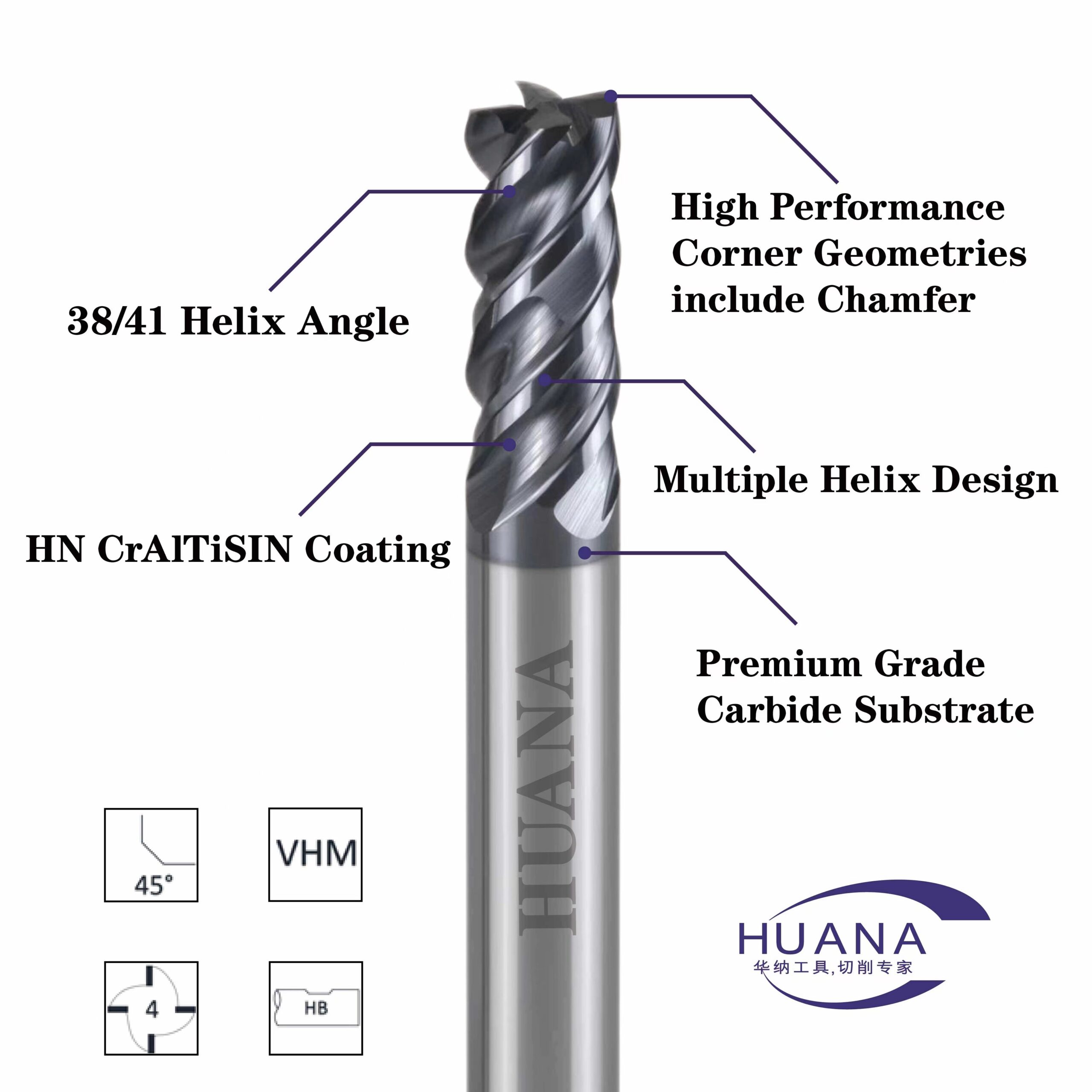

The variable core diameter milling cutter is a cutting tool designed for high-performance machining, primarily focused on roughing operations. It caters to the demand for improved metal removal rates in milling processes, offering an efficiency boost of 200% to 500% compared to traditional machining techniques. This introduction will highlight three key characteristics of the variable core diameter milling cutter: 1) 45° chamfer, 2) dual core diameter, and 3) uneven spacing.

45° Chamfer:

The variable core diameter milling cutter features a 45° chamfer, which serves multiple purposes. Firstly, it effectively removes burrs and sharp edges from workpieces, ensuring user safety and preventing injuries. Secondly, the chamfer protects the cutting edges, enhancing tool lifespan by reducing the chances of edge damage. The process of chamfering involves machining the sharp corners of the workpiece to create inclined surfaces, resulting in improved safety and tool longevity.

Dual Core Diameter:

The incorporation of a dual core diameter design in the milling cutter enhances its rigidity. This increased rigidity allows the tool to withstand higher cutting forces, reducing the risk of tool deformation during machining operations. The dual core diameter configuration enhances the milling cutter’s stability and robustness, enabling it to efficiently handle demanding cutting tasks with improved precision and durability.

Uneven Spacing:

The variable core diameter milling cutter features uneven spacing, which effectively suppresses the occurrence of cutting resonance during rough metal machining. This characteristic ensures smooth and stable cutting operations, preventing vibrations that could negatively impact the surface finish and tool life. The uneven spacing design optimizes the cutting performance, reducing the likelihood of chatter marks and enhancing the overall milling process.

common cutting material

This double core end mill works with high parameters in acid-resistant material, as well as few other materials such as K720

The K720 steel is a high-carbon tool steel produced by Bohler Industries, and its alloy composition is highly comparable to AISI O2 tool steel. It is commonly used as a machining material for the knives mentioned in this article, such as survival knives, straight knives, and jungle knives.

K720 tool steel is an ideal choice for outdoor knives due to its balanced performance in edge retention, toughness, and ease of sharpening. The balanced presence of carbon and manganese in its composition enhances its overall performance.