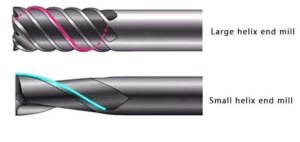

The effectiveness of the machining application is affected by a diverse selection of factors in various ways. It is common practice to ignore the helix angle. The helix angle is responsible for controlling the angle at which the cutting edge of the tool enters the work piece as the tool rotates. The helix angle must be increased for the entry of the cutting flute to happen in a more gradual manner. This results in a transition that is smoother as the cutting flute works its way toward achieving the desired axial depth of cut. Straight and spiral are the two primary styles of edge that may be found on carbide end mills. There are many different sorts of helix angles, such as 30 degrees, 45 degrees, and 50 degrees. In milling operations, the edge end mill has been used widely because, in comparison to the straight edge, it provides the advantages of light cutting, smooth cutting, high efficiency, and a wide range of applications. This has led to its widespread adoption. Now that we have that out of the way, let’s talk about how to choose the appropriate helix angle for the end mill.

What exactly is the helix angle?

The helix angle of an end mill is defined as the angle that is generated between the cutting edge and the centerline of the tool. Because of the helix that this cutter has, the chip load that is carried by the helical flutes of the end mill continues to grow. It suggests that the pressures begin to slowly increase at the point where the bottom point of the cutting edge first enters the material being cut, and continue to do so beyond that point. The cutting force of an end mill is composed of axial and radial components, respectively. The vibrations are caused by the radial component, which has a tendency to bend the end mill and presses it against the holder, while the axial component presses the end mill against the holder. Depending on the angle of the helix, there may be variations in the distribution of forces along the edges.

Because of the increased radial stresses caused by low helix angles, these tools are more susceptible to vibration and bending. These cutters, on the other hand, are capable of tremendous rates of material removal and huge chip loads. Because of this, they are an excellent choice for procedures involving roughing.

Higher helix angles are more flexible and less likely to vibrate and bend during the cutting process, which helps to lessen the amount of radial force that is exerted. They are able to generate an excellent surface polish, making them ideal for operations related to finishing.

How to choose the proper end mill helix angle is explained here:

- Take into account the Criteria of Your Application

What you intend to do will determine which tool is most useful for you to employ. The higher 45° helix is well suited for finishing applications, in which the tool is operating noticeably quicker but removing less material, whereas the slower 35° helix is well suited for roughing applications due to its increased strength and capabilities to carry a bigger chip load. This is because the higher 45° helix is ideal for finishing applications, in which the tool is operating considerably quicker but removing less material. In circumstances in which tool versatility is of the utmost importance, the medium 40° helix is a reliable choice since it can be used for both roughing and finishing, and it strikes a healthy balance between the benefits of slow and high helix angle.

- The function of the helix angle

Standard end mills are available with helix angles ranging from 15° to 60°. End mills for common use typically have a 30° angle. Any increase in helix angle reduces cutting forces and the amount of heat produced during milling by increasing the effective shearing action. Also enhanced is chip ejection. End mills with a lower helix angle are used on harder-to-machine materials where maximal edge strength and stiffness are crucial.

When using straight flutes, the load increases nearly immediately, which makes the end mills susceptible to self-excited chatter. Helix angles provide chip stress to the whole length of the flute in a progressive siding motion akin to a ploughs with a blade that is slanted off to one side. As a result, there is far less risk of noise and the cutting forces are much steadier. Higher helix end mills also often result in significantly superior work piece finishing. Helix angles of 50° and greater greatly lessen side stress on the mill, enabling peripheral milling of thin wall sections with much less deflection.

- Strategy for selecting the helix angle

The use of a big spiral angle end milling cutter is beneficial to extending the tool’s lifespan while cutting stainless steel materials that are challenging to work with because they have limited thermal conductivity and have a significant impact on the blade tip’s heat.

The helix angle also alters the features of the completed surface. For instance, high helix angle end mills may sometimes be utilized when machining with a smooth finish is necessary. However, the cutting resistance will rise and the force of the proper spiral angle cutter will increase when using an end milling cutter with a big spiral angle. As a result, appropriate actions must be taken, including employing a tool handle with strong clamping stiffness. Although the cutter’s stiffness may be guaranteed, narrow spiral angle end mills are sometimes utilized when cutting workpieces with low rigidity, such as thin plates.

- 60° helix angle type end mill

Suitable for high-speed cutting of difficult-to-cut materials such as stainless steel. For difficult-to-cut materials whose thermal conductivity is low and the tip temperature rises easily during cutting, the unique shape of the blade can suppress the effect of cutting heat on the tip.

- Large spiral end mill with a helix angle of 50°

The tool has excellent stiffness because to its adoption of a multi-edge design, and this allows it to reduce the amount of tool allowing in that occurs during side cutting. Sharp corners guard the cutting edge, which reduces the likelihood of the innovative chipping.

- Ball nose end mill use 30°-35° helix angle

In a ball nose end mill, the helix angle ranges from 30° to 35°, and it has a distinctive groove structure. These two features allow for high-speed processing while also providing great wear resistance. The surface roughness that is achieved after processing is satisfactory when using a chip breaker with fine teeth. Adopt a coating that is both highly lubricious and resistant to high temperatures.

- Square end mills with a helix angle of 35°-45° helix angle

For common milling applications like as slotting, profiling, and plunge cutting, square end mills are often utilized as the cutting tool. The cutting diameters of keyway end mills are intentionally undersized throughout the manufacturing process. This allows the mills to create a keyway slot that precisely matches the dimensions of the woodruff key or keystock. In most cases, the specialized helix angles for square end mills range from 35°-45° degrees.

- End mill with a 45°-55° helix angle for aluminum

An end mill’s helix angle is determined by the angle that is produced between the centerline of the end mill and a straight-line tangent along the cutting edge. This angle is measured in degrees. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. In most cases, the specialized helix angles for aluminum range from 45 degrees to 55 degrees. You may also get variable helix end mills, which are a terrific option for lowering chatter and harmonics while simultaneously increasing the amount of material removed from the workpiece. For more conventional roughing and slotting operations, a helix angle in the range of 45° to 55° is a reasonable option.

The Advantages and Disadvantages of High Helix Angles

There is value in using a variety of helix angles since each angle will result in a distinctive set of outcomes. A higher helix angle may result in less tool pressure, which in turn can lead to better finishes and less heat accumulation. When compared to helix angles of a lesser degree, a 45-degree helix has the potential to boost the vertical force of a tool, which eventually results in less strain being placed on the cutter. The progressive entrance of the cutting edge enhances the tool’s efficacy. This is true whether the advanced cutting tool programs are being used in a machining center or the tool is being manually machined. This is because the higher helix angles can be fed at a greater rate.

Ejecting the chips at a more acute angle is another way in which a higher helix might assist with chip management. In materials in which we purposefully aim to disperse the heat on the chip itself, proper chip evacuation may assist avoid chip packing or re-cutting of chips, which can be a costly process. Higher helix angles are often suggested because they operate well on sticky materials like as aluminum, and they excel in stainless steel and heat resistant alloys. On the other hand, the size of the helix directly correlates to the amount of reinforced strength that each cutting edge has. There is a risk that a high helix may assist pull the end mill out of the collet featuring because of the larger vertical force that it exerts. This is one of the drawbacks of having a high helix (however most end mills pulling out of collet featuring is due to user error or cutting parameters that are too aggressive, or the end mill not being tight enough in the collet).

Low Helix Angles: Their Advantages and Disadvantages

Lower helix angles provide improved edge strength, which is beneficial in materials like cast irons and tougher steels. Tools having a helix angle of less than 40 degrees are often better suitable for roughing tasks because to their increased strength. However, the finishing quality is diminished when using these sorts of tools; however, this drawback may be circumvented by performing a finishing cut with a higher RPM and a slower feed, during which the tool takes away just a little quantity of the material being cut. Therefore, applications that need heavy cutting and where finish is not as much of a concern are better suited for tools with a low helix.

Finally yet importantly, the angle of the helix is one of the most important characteristics of the helix edge end mill. The degree to which the helix angle is altered has a significant bearing on the cutting efficiency of the tool. The modification of the helix angle in the course of tool production has been feasible thanks to the development of CNC machining technology. When manufacturing and selecting spiral-edge end mills, it is important to combine the performance of the machine tool and tooling fixtures, according to the performance of the processed material and the processing accuracy. Comprehensive consideration of factors such as machining efficiency, tool material and tool life, and optimizing the size of the helix angle will undoubtedly improve the cutting performance of spiral-edge end mills.

Conclusion

In conclusion, a machinist has many considerations to make while selecting the appropriate tools for each job. A machinist is required to take into consideration the helix angle of each tool in addition to the material, the criteria for the finish, and the permissible run times. Using a helix angle that is too high when it is not required will shorten the life of the tool, and using a helix angle that is too low when it is not required can cause chattering and a poor finish. The whole information on the helix angel option for end mill can be found up above; we hope that it will be helpful to you. Feel free to get in touch with Huana if you need any more information!