What is Carbide Drills?

A carbon-containing substance (carbide) that contains an element less electronegative and a carbon-containing substance is what is meant by its name.

It was formed from the combination of cobalt and tungsten carbide. This was an alternative to diamond, and it was widely used for cutting knives and swords. A very important element, apart from cobalt, was also included in the mix in order to ensure that particles could stay together.

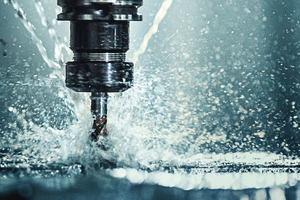

An object made from metal was formed by applying heat or pressure to it during the production process. By further shaping this mass of metal, the user has been able to convert it into the tool of his or her choice, and the user will be able to carry out the task of creating a useful, functional instrument. In fact, it is the process of shaping solid carbide drill bits for metal that are responsible for the creation of these tools.

What is an HSS drill?

There is a steel known as High-Speed Steel that is an alluring high-alloy tool steel and is termed as such because it is abbreviated HSS. Its hardness contributes to its use in manufacturing tools as well as the ease with which it can be ground. Although HSS is a relatively unbreakable material, it can be ground very easily. Due to the materials’ ability to hold their hardness at temperatures of up to approximately 1200°, this material can perform multiple times faster than conventional tool steels or cold worked tool steels, in comparison to conventional tool steels or cold worked tool steels. A special heat treatment process described in the above paragraph is necessary to achieve this result. During this process, the steel is annealed at temperatures over 1,200°C and then cooled.

As the basic structure of HSS is primarily composed of carbon and iron, the resulting hardness is directly related to its basic structure. A high-alloy steel can be produced not only by alloying the steel with more than 5% alloying additions but also with the addition of additional zinc.

Difference Between Carbide and High-Speed Steel

As the atoms of carbon are surrounded by less electronegative material in carbon dioxide, they are also less electronegative. The final point to be made is that tools made from carbide will last longer than those that are not, since carbide is an extremely durable and hard material. A high melting point type of steel, such as high-speed steel, is used for cutting tools as it has the capability of being good high-speed steel. Tools made from high-speed steel don’t last long unless they’re coated with a suitable material, such as titanium nitride.

High-Speed Steel vs Carbide

Carbide Cutting Tools Have Better High-Heat Tolerance

Irrespective of whether or not you play professionally, it is important you do not neglect the problem of overheating when playing. It is of the utmost importance to keep the temperature within a reasonable range at all times during the playing process. A carborundum blade provides better thermal resistance than a high-speed steel blade, so a carburated blade can be a great choice if you want something that will last a long time.

It is because of their increased resistance to heat that they can withstand temperatures that are higher than normal without losing their effectiveness or efficiency. The extreme temperature of steel can cause it to deform permanently, thus shortening its lifespan and requiring its replacement immediately.

Both beginners and more experienced users would benefit from using carbide circular saw blades to solve this problem. The beginners would be greatly relieved if the inability to maintain the temperature for a prolonged period was not a concern because we don’t have to worry about that at all. As we do not have to deal with maintaining temperatures for prolonged periods, it would be nice if beginners did not need to worry about that issue. For that reason, we expect professionals to give more attention to the process of cutting. If they reduce their concern about overheating they will be more efficient and they will be able to perform at a higher level of accuracy.

HSS Tools Are Less Expensive

When it comes to pricing, HSS tools are the best. Purchasing carbide drill bits for metal is more expensive than a tool made from high-speed steel, the first thing one notices when analyzing the market.

It is no doubt that HSS units are better when it comes to their cost; they are also known to be more reliable and have longer warranties. It is possible to purchase these tools at a reasonable price. In this way, they are perfect for those who are learning to play the piano because they can be used for practising. Certainly, if there is a breakage, it is reassuring to know that you have not spent a fortune on a tool.

It is important to realize price has an impact on the tool’s durability. Neither of the above can be expected to be impressively long-lasting even if you are careful and do not damage the tool by error.

Carbide Lasts Longer

There are a few downsides to HSS tools, including the fact that carbide drill bits for hardened steel can last much longer than HSS tools. Choosing the right tool depends on finding the perfect balance between these two factors and is critical. When you purchase an HSS unit you will have to purchase a new one after the original one lasts only a short period of time. It is, however, indicative that if you use a carbide chainsaw blade for a long time, you could be making a wise investment in the long run.

Depending on the size of the carbide saw blade you need, the cost may be higher than if you get a standard one. While it may seem like a significant cost, it may be an appropriate cost if you are looking for a tool that has long-lasting qualities.

The key to achieving optimal longevity with any product is ensuring that regular maintenance is carried out regularly. In order to keep your carbide drill bits for hardened steel in the best possible condition, you must clean them regularly. Therefore, this will ensure that the device will be working properly without any residues compromising its performance, causing overheating, breakage, or anything of the sort.

It is also recommended that you store the device in a safe place after use. If you decide to store it in that way, you will need to make sure that nothing will happen to the unit when you’re not using it, and that it won’t be damaged while it’s not in use.

HSS Tools Are Easier To Sharpen

Carbide drills with coolant holes are longer lasting than their steel counterparts and we have already seen that carbide is better at cutting. It seems that steelworks wear out much faster than carbide drill bits for metal works as we have observed from our experience. The consequence of this is that they have to be sharpened frequently. On such materials as metals, you will only make these units dull more quickly if they are used on them. On such materials as metals, you will only make these units dull more quickly if they are used on them.

Fortunately, the sharpening process is relatively easy and the process takes only a few minutes. However, the general truth remains that sharpening takes time to complete and requires dedication on the part of the user.

Alternatively, carbide drill bits for hardened steel are longer-lasting, and therefore they do not need to be sharpened as frequently, as opposed to steel tools. To ensure that the product is functioning optimally, make sure that you check the sharpness of the blades frequently. It is essential to begin using a carbide saw blade sharpener as soon as the device becomes dull.

Getting carbide sharpened could be achieved using a slow-speed grinder with a little bit of ingenuity. There is the option of taking the tool to one who owns a sharpening unit in his workshop or to someone who owns his or her sharpening unit.

Carbon cutting tools provide smooth finishes

In the case of an important project involving a cutting process, it is only natural to be concerned about the results. Therefore, tool operators must make clean, accurate, and smooth cuts whenever they operate their tools. Cutting with carbide drill bits for metal is one of the easiest and most effective ways to ensure these outcomes.

The strength of carbide makes it an ideal material for tough applications since it is stronger than high-speed steel. There is also no danger of overheating with this product since it is also resistant to high temperatures.

Moreover, the effect of this will be to make the cuts clean and smooth. It is nice to know that carbide remains sharp for a long time and doesn’t wear off. A dull blade won’t ruin your work.

Carbide Tools Are Durable

There are several benefits of using carbide tools, such as their durability, long life and their strength. Thus, they are versatile and can be used with a wide range of materials, allowing them to be applied to a wide variety of situations. Furthermore, when you want to cut tools that are being reused, it is wise to use carbide as the material for cutting.

For materials such as hardwoods and similar materials that leave a great deal of dust and debris, carbide units would also be an excellent choice. They will cut through a lot of dust and debris at the same time as ensuring that the tool is not damaged in the process. The tool should always be protected from damage at all costs. You must take a moment to remove debris if you find there to be too much. When you do so, your tool will perform better and your results will be improved.

Steels of High Speed – Still Very Significant in Metal Cutting

There are many grades of high-speed steel, but High-Speed Steel is by far the most well-known. There are usually 18% tungsten, 4% chrome, 1% vanadium, 0.7% carbon, and zero iron in a typical high-speed steel material. A high-speed steel tool harness has a 62-64 Rockwell hardness. When cobalt is added to HSS, it can increase its strength and wear resistance by from 5 to 8%. The drills that have been made with the addition of the cobalt are normally referred to as cobalt drills. These are used in high-end applications for drilling.

HSS: Best Overall

HSS is an extremely high-speed steel grade that is, typically, engineered to use lower cutting speeds than conventional steel grades. During the last few years, the development of HSS has made it easier to make the transition from HSS to Carbide tools.

As it is known, HSS is a powder made from a similar process to the manufacture of Carbide. In addition to their outstanding toughness, tools made from this material have a finer grain structure, allowing them to achieve a higher hardness than HSS. In this way, you can have a tool that can be used on hard materials like ceramics and ceramics-related materials and will last longer than a standard HSS tool.

In rough milling applications, along with applications in automotive manufacturing, there may also exist a need for HSS due to the heavy cuts made in a single pass. An aerospace component is an example of a product that contains a long cycle time, meaning the parent company may prefer to run the machinery ‘lights-out’ overnight to do as much rough as possible. Carbide endmills are not a good alternative because they have brittleness. In this case, HSS roughing endmills are the preferred option because they do not have this brittleness.

Final Thoughts

From what we can see, each tool has distinct advantages. One of the advantages of HSS machines is that they are not only affordable, but they are also fast. However, carbide is a much stronger, more durable, and more effective material that can handle the toughest of applications. If you are planning to purchase these devices, it is essential to select a trustworthy manufacturer of carbide drills with coolant holes.

In choosing a company, you need to look at their experience and readiness to meet your needs as the most important criteria.