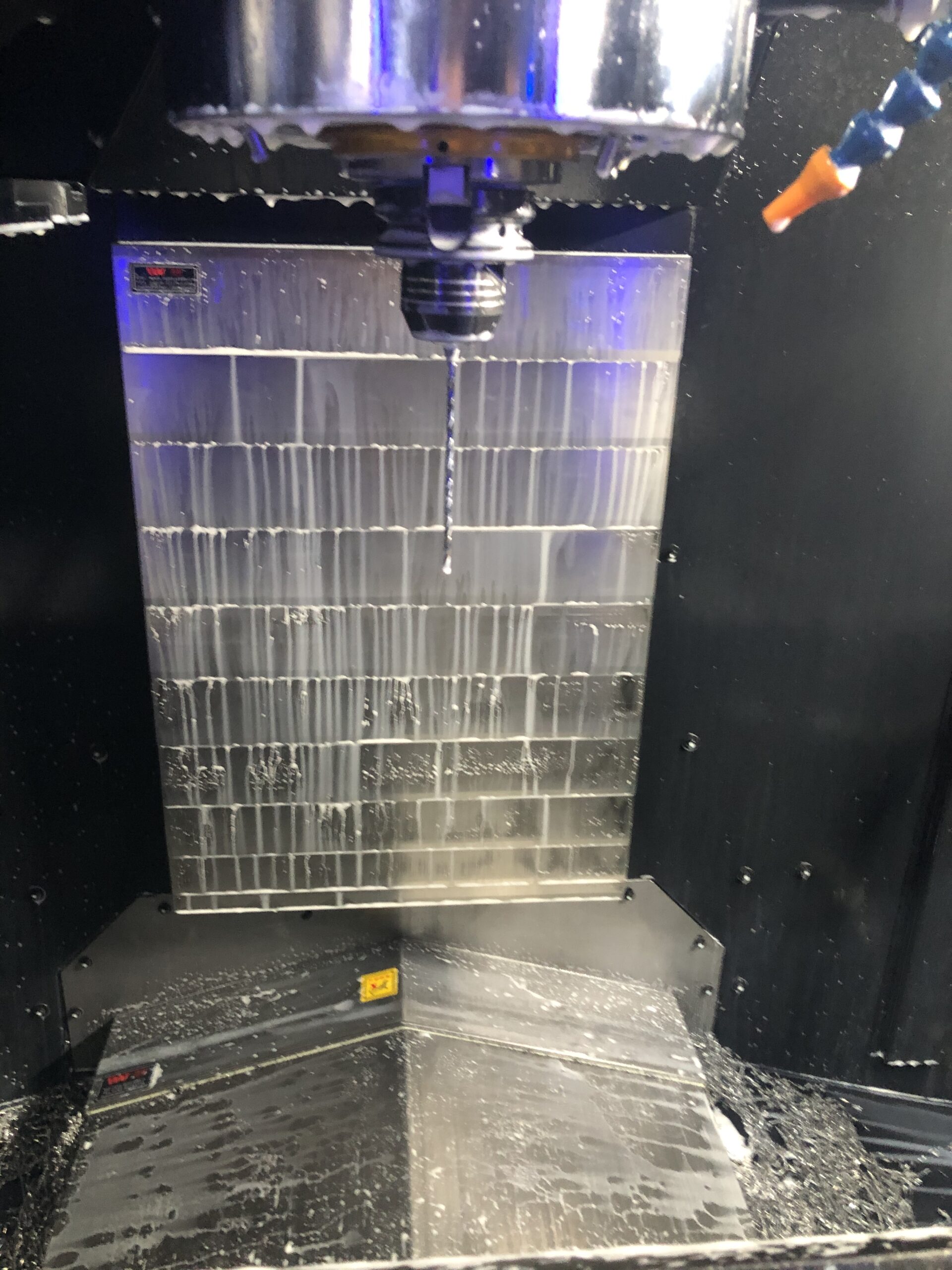

The development of a “deep hole” in which the diameter is 10 times greater than the depth is required in a variety of industrial applications. In order to drill holes in a straight line, specialized deep hole drills with a particular tool for drilling deep holes is necessary.

What is Deep Hole Drilling?

A hole is regarded to be deep if it has a depth-to-diameter ratio (D:d) that is larger than 10, and in general, holes with this ratio are considered to be deep. Deep hole drilling into metal has a variety of applications across a number of different industries. Its roots can be traced back to the requirement for gun barrels that were straighter and more accurate, and it expanded as other industries began integrating deep hole drilling processes to improve their own applications.

Deep hole drilling comprises of BTA drilling and gun drilling, in addition to other procedures tailored for specific tolerance requirements and often carried out on BTA-style deep hole drilling equipment. BTA drilling is the most common type of deep hole drilling. Deep hole drilling is capable of attaining tight diameter control, straightness, and excellent surface quality in workpieces, and it is employed in a variety of materials ranging from aluminum to super-alloys.

Deep hole drilling procedures make use of specialized tools and setups in order to supply high pressure coolant, remove chips in a clean manner, and achieve depth-to-diameter hole ratios in metal that are greater than what a standard CNC machine is capable of doing. Because of this, producers are able to consistently, accurately, and efficiently meet the production needs as well as the tolerances of their manufacturing processes.

The process of deep hole drilling is often carried out using specialized equipment designed specifically for the task. These machines are built and put together in a way that optimizes the procedures for straightness and efficiency. Deep hole drills are now capable of gundrilling up to a certain depth-to-diameter ratio because technological advancements have made it possible for them to be outfitted with high pressure, through-spindle coolant. UNISIG manufactures extremely competent BTA and gundrilling machines, some of which have applications with D:d ratios greater than 400:1.

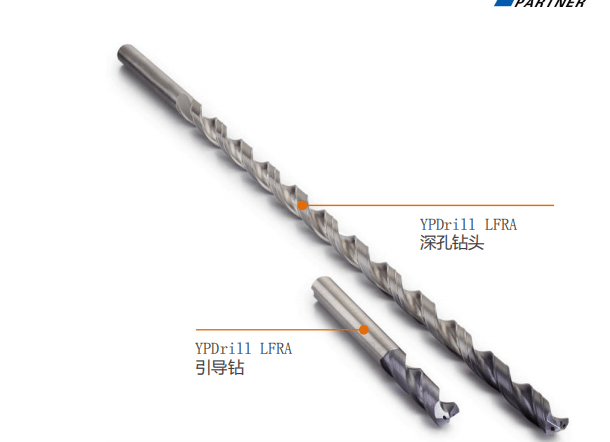

Deep Hole Carbide Drills

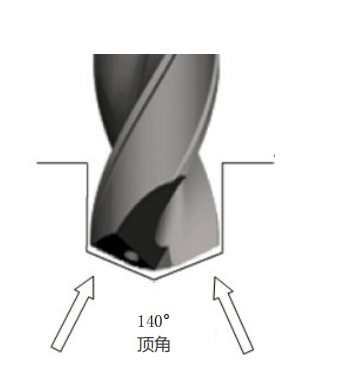

These spiral-flute deep hole carbide drills have an innovative flute geometry that was created for optimal chip evacuation from deep holes in a variety of materials. This geometry was developed for use by spiral-flute drills. The tools have a maximum coolant duct profile so that they can provide the cutting edge with the most effective possible amount of coolant. It guarantees both an effective supply of coolant to the cutting edge as well as optimum chip removal from the cutting area. Chips may be removed without any issues even from very deep holes thanks to the design features of this drill, which, when combined with the optimum cutting settings, result in clean cuts. Chip packing and the ensuing jamming of the tool are successfully avoided thanks to this feature.

Process of Deep Hole Drilling

Rotating Tool

- Components that are not symmetrical, or spherical sections with holes that are not centered, are typical applications for this technique

- The speed of the tool spindle is what determines the cutting speed

- When compared to rotating the workpiece or using a counter-rotating method, drill drift can often be rather substantial

Workpiece Rotating

- Utilized most frequently for spherical components that have a hole that is deep and centered

- The speed of cutting is governed by the component and is balanced to allow for high rotation speeds

- When compared to using merely a revolving tool, drill drift is significantly minimized

Workpiece with Counter-Rotating Tool

- Ideal procedure for spherical objects that have a hole that is both deep and on center

- The rate of cutting is dependent on both the tool and the workpiece rotating at the same speed

- Offers the highest possible degree of hole straightness and concentricity

Applications of the Deep Hole Drills

There are a variety of applications for deep hole drills, and practically every industry uses them. Each of these applications has its own set of stringent criteria and one-of-a-kind problems, such as tight tolerances, difficult materials, and aggressive production targets.

The following are some samples of common applications, processes, and tolerances. These examples are not actual part, but they are representative of what is feasible when employing deep hole drills with the appropriate machine setup, tooling, and process understanding.

- Fuel Injector Bodies

For high-precision, high-volume items, it is possible to make the many holes at the exacting tolerances necessary by using a 3-spindle gundrilling center that is automated with robotics and conveyors.

- Fuel Rails for Diesel Engines

Gasoline rails ought to have very small holes that are completely straight and won’t break when subjected to the pressure of the gasoline. The utilization of gundrilling makes it feasible to bore holes that are in accordance with these very stringent requirements, which are quite exact.

- Sheet for Heat Exchangers in Tube

It is feasible to correctly drill thousands of holes in a short period of time using a multi-spindle tube sheet drilling machine, maximizing productivity in the process. This is accomplished by drilling the holes one at a time.

- Equipment Used for Landing an Aircraft

Drill and shape the landing gear actuating cylinders using high-strength alloys while preserving an exceedingly tight straightness tolerance.

- Fluid Assembly Ends

In order to construct the apparatus needed for hydraulic fracturing, a block of steel is given a number of holes that need to be drilled into it. There is a need for machines and equipment that can meet the challenge posed by a substantial workpiece that also has accurate tolerances.

- Hydraulic Cylinder Inside Bore

To produce superior hydraulic cylinders, an existing bore should be finished to the point that it satisfies the requirements for a surface polish that is as reflective as a mirror.

- Oilfield Exploration Equipment

It is possible to drill holes in long workpieces with extraordinary depth-to-diameter ratios without making compromises the accuracy of the roundness or wall thickness of the holes. This is accomplished by using a drill bit with a larger diameter than its depth.

- Exploration of the Oil Field Downholes

Trepan holes may be drilled in long workpieces with extraordinary depth-to-diameter ratios without affecting the accuracy of the hole’s roundness or wall thickness. Trepan holes are named for the trepan tool, which was developed in the 19th century.

Difficulties of Using Deep Hole Drills

The following are the four most important obstacles to overcome:

- Chip evacuation;

- Walking

- Tool runout

- Coolant evacuation

The behavior of the drill bit having a tendency to twist about the axis of rotation while it is working is referred to as the phenomenon known as runout. When the length of the drill is increased, there will be more runout, which will result in the hole having a wider diameter. It is simple for the axis of the hole to become off because of the excessive length of the drill pipe, its lack of rigidity, and its sensitivity to vibration. This has a detrimental effect, not only on the accuracy of the machining but also on the effectiveness of the manufacturing.

An activity referred to as “walking” takes place when the drill tip first makes contact with the workpiece in the process of drilling. If the surface being drilled isn’t exactly perpendicular to the axis of rotation of the drill, then the drill will be driven in that direction by a force that acts laterally (and a long, thin drill can bend slightly.) As a consequence of this, the hole will most likely be drilled at an obtuse angle and at the incorrect place. It is also possible that the drill will be harmed by this. Regardless of whether the surface is as-cast or has been rough milled, the possibility of the same event happening still exists.

It is necessary to remove the material that was cut away at the bottom of the hole in order to make room for the drill to progress further. When drilling deep holes, these chips have a propensity to wind their way around the flutes of the drill and accumulate to the point where they scrape against the sidewalls of the hole. As a direct consequence of this, the temperature will build, which will ultimately result in the drill either failing or being jammed. Chip removal and bit wear can only be assessed by listening to the sound, observing the chips, monitoring the machine load, checking the oil pressure, and paying attention to a variety of other indicators. It is difficult to get a good look at the cutting condition itself.

The use of cutting fluid to maintain a cold cutting contact is an integral part of the vast majority of the processes that are involved in precision machining. It is not easy to get liquid all the way to the bottom of a hole that is quite deep. There is a lot of work that needs to be done. As a consequence of this, the temperature at the drill tip increases to the point where it has the potential to cause damage to the workpiece or even weld to it. It might be challenging to remove chips from the surface. If the chip chamber becomes clogged, the drill bit will experience damage as a result.

Deep Hole Drill Advantages

1) The deep hole drilling machine is constructed of high-quality cast iron after secondary treatment, so the stability of the casting and accessories is extremely excellent, relatively strong stiffness, and it is thus much appreciated by users. Furthermore, the popularity of the deep hole drill is naturally connected to the technical innovation and maturity.

2) Three axes of deep hole drills are now utilizing imported good stiffness and heavy load and high speed and accuracy of the ball in a straight line guide rail, so as to assure that continues on the deep hole processing, processing of high accuracy and the service life of guide rail, now using the process of deep hole drill can offer greater torque, so that more practically applicable.

3) As a result of the maturation of the technology, the spindle of the modern deep hole drill is entirely comprised of an imported motor. This not only guarantees that there is adequate power, but it also enables the motor to be switched freely and correctly during high and low speed processing. In order to guarantee the dependability of the machine’s operation, an automated oil-cooling system has been included. This system ensures that the machine can maintain a temperature that is consistent throughout the processing.

4) Since the deep hole drill is computer controlled, system compatibility is also getting better and better. This allows software such as CAD and CAM software to be compatible, which tends to make the machine in better operability, processing can be customized according to the particular job demand function, as well as deep hole drilling machines have become the favorite of the industry.

What has just been discussed is the reason why the deep hole drill is being utilized in the deep hole processing on an increasingly regular and widespread basis. Because of all of the benefits that it offers, the deep hole machine tool has quickly become the most popular piece of machinery in its field. In addition, as a result of advances in technological know-how, today’s machine tools are able to have their functions modified in accordance with the particular specifications of a given project, which is also a very useful feature.

Precautions For Using Deep Hole Drills

1) The coaxiality of the centre lines of the spindle and tool guide sleeve, toolbar support sleeve, workpiece support sleeve, etc. should fulfil the criteria in order for deep hole cutting and machining to be successful.

2) The depth of the hole that has to be cut should be at least as much as the diameter of the workpiece. The system for the cutting fluid should be clear and functioning normally; On the machined end face of the workpiece, there should not be a central hole, and drilling should be avoided on the inclined plane; It is important to maintain the usual shape of the chip in order to prevent the production of strip chips that are straight; When processing the through-the-hole, make sure you use a higher speed. To minimize damage to the drill, limit the speed of the machine when it is close to breaking through the material, or stop the machine entirely.

3) Cutting fluid for deep hole machining: because the process of deep hole machining generates a significant amount of cutting heat that is difficult to dissipate, it is essential to provide an adequate amount of cutting fluid to lubricate and cool the tool. This is because the cutting heat is not easily dissipated. In most cases, the 1:100 emulsion or the severe pressure emulsion is the one that is chosen; Extreme pressure emulsion or high concentration extreme pressure emulsion is selected for use in situations in which high machining precision and surface quality as well as machining toughness materials are required. The kinematic viscosity of cutting oil is typically between 10 and 20 cm2/s at a temperature of 40 degrees Celsius, and the flow velocity of cutting fluid is between 15 and 18 metres per second; When the diameter of the machining is relatively small, you should use a cutting oil with a low viscosity; The ratio of cutting oil might be 40% EP vulcanised oil, 40% kerosene, and 20% chlorinated paraffin when doing deep hole machining that requires a high level of precision.

Useful Tips For Deep Hole Drills

- In order to guarantee the dependability of the end face seal, the end face of the workpiece is oriented such that it is perpendicular to the axis of the workpiece.

- A preliminary shallow hole is drilled on the hole site of the workpiece before the formal machining is performed. This hole can play a guiding and centering role throughout the drilling process.

- Automatic tool feeding is highly recommended whenever possible since it helps extend the useful life of the tool.

- If the guidance components in the liquid feeder and the moveable center support get worn over time, they need to be changed as soon as possible to prevent the precision of the drilling from being compromised.

- Continue feeding the drill into the pilot hole at a maximum of 50 revolutions per minute and 12 inches per minute (300 millimeters per minute) until you are approximately 1/16 inch from the bottom of the pilot hole (1.5mm)

- At this stage, the pilot hole will provide adequate support for the conclusion of the drill.

- After that, you may activate the coolant, and you can gradually increase the speed of the engine up to 75% of the recommended federate and 50% of the required rpm.

- Once you have reached a distance of about 1xD below the bottom of the pilot hole, you are in a position where it is safe to increase the rpm and feed rate to 100% of the required speed and feed rate.

- When playing through holes, slow down by half and federate up to seventy-five percent immediately before the escape.

- Before pulling the drill out of the hole, ensure that the coolant has been turned off and that the speed has been lowered to 50 revolutions per minute.

Best Practices for Precision Deep Hole Drilling

The machine tool is the first step in the production of precise and deep holes. On a CNC machine equipped with a spindle of superior quality, one may anticipate the best possible outcomes. Runout is reduced, and a high level of control is provided over the drilling cycle as a result of this. (It is important to bear in mind that when working with spherical components, it is often preferable to spin the workpiece while keeping the drill stationary, or even to have both components counter-rotating.)

The toolholder and the actual drill follow next in the sequence. The holder is responsible for maintaining the drill’s position on the axis, and the drill itself needs to be perfectly straight and symmetrical about the axis.

It is necessary to prepare the surface in order to prevent the drill from wandering. Milling a flat pad may be part of this process in addition to fixturing the workpiece to place the surface in a perpendicular position. Although beginning with a centre or pilot drill guarantees that the hole will be in the appropriate location, doing so requires yet another tool change.

The actual drill that is used has to have the capacity to bore deep holes. The most important need is a central hole, which will be used to transport cutting fluid to the cutting tip. The cutting temperatures will drop as a result, and the chips will be expelled. Instead of having two cutting edges, a deep hole drill bit designed specifically for larger holes will only have one of those edges. This again helps remove chips from the surface.

“Peck” drilling is an option that can be used in situations when it is not viable to transfer fluids through the hole. This requires removing the drill from the hole, which will also remove chips from the hole, and then replacing the drill. Some machine shops like to employ a set of drills that gradually expand in length since doing so will increase the amount of time spent on each cycle.

Conclusion

All of HUANA’s deep hole drills benefit from our use of cutting-edge technology, which enables us to achieve extremely tight tolerances and outstanding precision. Our services are both immediate and cost-effective, and we will provide you with an expert solution in the shortest amount of time possible thanks to the availability of a broad variety of deep hole drills. Please get in contact with HUANA as soon as possible for further details.