Drilling is the most prevalent type of machining technique, and drills may be found in just about every workplace. When trying to save expenses, businesses search for drilling methods that are both quick and precise. Drills made of carbide are among the most useful tools that can be found in every toolkit. Your drills need to be able to cut holes in a variety of materials, including wood, plastic, metal, and others, while following to exact dimensions and quality requirements in order to be effective for your business or product. However, if the drill bits that come with your carbide drill are not equal to the task at hand, even the greatest carbide drill in the world won’t be of much help to you. The effectiveness of your drill is not actually determined by the power of the drill itself, but rather by the bit.

This article is going to discuss carbide drills, covering the material that it is made out of, as well as the applications of carbide drills in a variety of industries.

Different Types Of Carbide Drills

Cutting tools like drills are used to make holes in many kinds of work materials. Machine tools such as drill presses, lathes, milling machines, and machining centers all make use of them in various capacities. Materials that can be used to make drill bits include high-speed steel, alloy carbide, high-speed steel powder, and high-speed steel. Some of these materials have coatings that are based on silicone, TiAlN, TiCN, or TiN, while others have surface treatments that include steam oxide treatment to improve oil retention on the surface. In addition, there is a kind of machining known as “thinning,” which is performed on the tip of the bit in order to lessen the thrust stress that is imparted to it during drilling. There are many different shapes of thinning, such as the X-shape, which is used for machining deep holes; the R-shape, which is used for machining stainless-steel-based workpieces; and the S-shaped, which is used for machining cast-iron- or non-ferrous-based workpieces. Each of these shapes is utilized in accordance with the various characteristics and applications that they are designed for.

- Solid Carbide Drills-Flat Drills

Flat Drills are typically fabricated by heating a thin stick of high carbon steel until it hardens and tempers into the desired shape. The cutting edge of the drill is then hardened. The most significant benefit of a flat drill is that it can be used for solid metals, and its cutting points are maintained at a ninety-degree angle, in contrast to the situation in which the cutting points of any other kind of drill would break. Flat drills are not used for the borehole in iron material.

- Twist Drills

Thin rods of alloy steel and high-Speed steel are typically used to make the thick drills and twist drills, which are normally utilized to get the holes to the correct size, rapidly, and cleanly.

Features:

-Traditional twist drill design with carbide inserts.

-Improved heat dissipation.

-Balanced cutting performance.

- Straight Fluted Drills

This Straight Fluted Drill is characterized by flutes or grooves that run in a direction that is perpendicular to the axis of the drill; nevertheless, this drill is not appropriate for use in ordinary practice and does not immediately pop out of the hole. Copper, drilling brass, and other softer materials are the primary applications for Straight Fluted Drills. The drilling twist brass goes quicker than a drill feed, and it is utilized to dig or drill into the metal.

- Double Fluted Drills

Due to the fact that it is superior to other types of drills in terms of both strength and quality, these Double Fluted Drills may be used for any kind of job. These two flutes of drills are located directly across from one another.

- Multi Fluted Drills

Multi–Fluted Drills, as the name suggests, have more than two flutes in the drills. This feature distinguishing characteristic is that due to its bigger edge of cutting, multi–fluted drills can bore a hole quickly and also clean the hole quickly. Multi–fluted drills are used for jobs that require a high level of precision.

- Counter Boring Drills

There is another name for the counter boring drills, and that is the Counter boring Cutter. When screws are installed, a counter boring is performed on the work surface. Allen screws can also fix the work surface in the same manner as a counter screw. Counter Boring Drills are typically put to use when one has to enlarge an existing hole or bore a hole all the way up to the level of the screw head. In addition, the boreholes are cut at an angle ranging from sixty degrees to eighty-two degrees as viewed from the top.

- Installer Drill BitsThese installer Drill bits have the appearance of auger drill bits, and they are used for drilling holes and installing cables in security systems as well as entertainment reasons. This drill may also be used to drill into masonry, wood, and plaster. The installer bits are lengthy and can reach up to 18 inches in length. Drills for Masonry

- Masonry Drill Bits

Masonry Drill Bits are utilized in the construction of structures made of stone, concrete, and brick. When these bits become worn out, replacements must be obtained for them. The same thing happens if you wish to drill into the concrete for an extended length of time, because this causes the tip to melt. Altering the drill bit used to remove the concrete may be done quickly and simply, which should help alleviate the problem.

- Glass Drill Bits

Glass drill bits may be used to bore holes in a variety of materials, including plastic, glass, brick, marble, composite material, hollow brick, and others. In addition, this type of glass drill is able to withstand high temperatures very well.

Benefits of Using Carbide Drills

Because of its high level of hardness, carbide is an excellent material for use in drilling. As a consequence of this, carbide offers a more consistent and long-lasting work life. By adopting carbide materials, businesses are able to keep their tools operational in the field for longer periods of time, hence reducing the amount of time lost due to downtime and maximizing the amount of time spent working on a project.

Carbide drills are superior than high-speed tools in terms of both productivity and cost-effectiveness. This is because carbide drills keep their cutting edge hardness even when subjected to high machining temperatures, which are caused by high cutting speeds. Carbide has a high melting point, coming in at 2,870 degrees Celsius (5,200 degrees Fahrenheit).

Carbide drills can either be made entirely of tungsten carbide or have only their tips coated with carbide cement. Because they last so much longer than other types of drills, carbide drills are the tool of choice in the construction, mining, agricultural, automotive, and machine shop industries. When working with any type of metal or drill, there is a constant risk of wear and strain, dulling, and even breaking. In order to further extend the amount of time that carbide drills may be used, they can be resharpened in machine shops. After that, the carbide scraps, filings, and sludge can be transferred to carbide recyclers in order to receive the highest possible price for the scrap carbide available at the time. Huana Tools gives detailed advice on how to correctly send carbide scrap to their offices as well as how to keep the scrap carbide metal distinct from scrap metal made of other metals.

The fact that carbide drills have a higher hardness than other types of drills means that they have a longer operating life than other types of drills. When used in continuous applications, hardened steel does not have the same level of durability as carbide. Carbide is a substance that allows businesses to keep their tools operational in the field for extended periods of time, which eliminates the need for downtime and saves time that would have been spent working on a project.

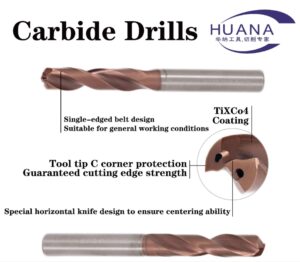

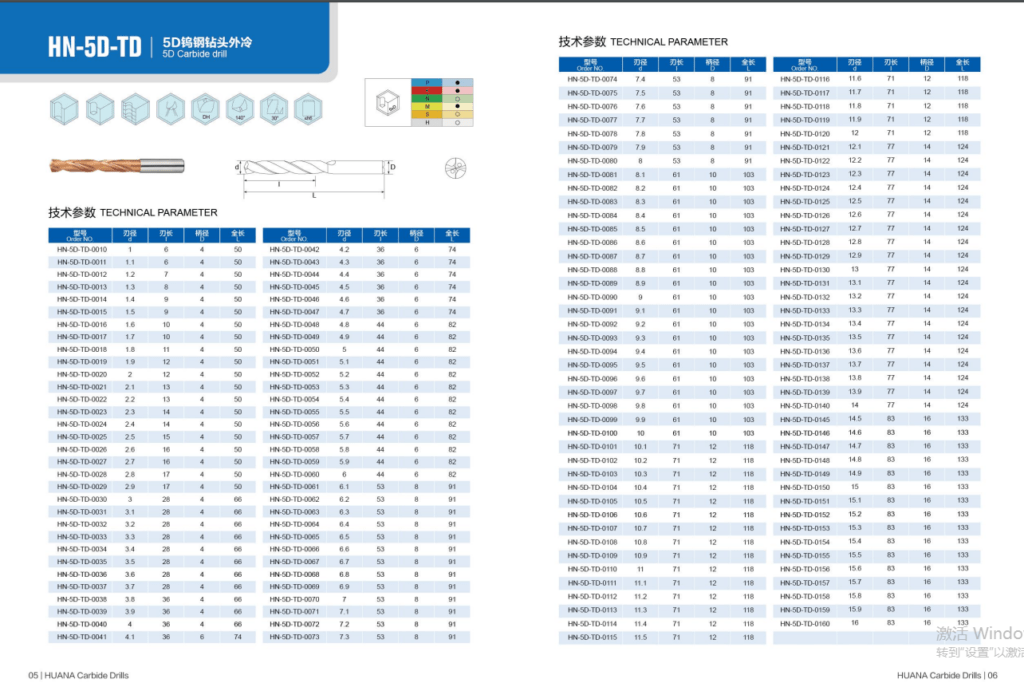

5D Carbide Twist Drills

High performance 5D coolant hole carbide twist drills have a wide range of applications, are adaptable, and can be used to efficiently machine a number of materials, including steel, stainless steel, and cast iron. A liner cutting edge with exceptional strength and an optimized drill point structure are features of 5D carbide twist drills with coolant holes. Testing and simulation are combined to achieve better overall performance. Professional coating aftercare ensures minimal resistance, high productivity machining. Double edge line design is used in 5D coolant hole carbide twist drills to increase machining stability. Solid carbide rods of the highest caliber were used to manufacture all 5D carbide drills. Excellent strength and wear resistance in a very reliable grade.

3D Carbide Twist Drills

High-accuracy drilling with a 3-flute design that produces good cutting balance and reamerless processing is made possible by 3D carbide twist drills with cooling holes. The lubricating hole on 3D carbide twist drills allows for high-speed, high-feed drilling up to a specific depth. Stainless steel may also be drilled using 3D carbide twist drills. With a coolant hole 3D carbide twist drill, which supports steels and improves drilling efficiency. In order to significantly enhance chip evacuation and decrease cutting resistance in the 3D carbide twist drill, new creative design is implemented. This enables steady drilling with tiny machines. The long tool life of 3D carbide twist drills is made possible by improved heat and wear resistance as well as lubricating performance from excellent coating.

Applications of Carbide Drills

- Wood Projects

The vast majority of the drills you’ll use for woodworking tasks have a brilliant finish. The shape of the drill bit is more crucial when drilling into wood than the type of coating and bit material. The wide variety of wood types available to you will be appreciated if you are a woodworker. Both softwoods and hardwoods are abundantly accessible to you. There are also several tasks available for you to work on. This might involve anything from boring through wood when building a house to drilling holes in furniture. Because there are so many different types of woodworking jobs, bit manufacturers have created some inventive and specialised equipment. There are thin bits, thick bits, long bits, short bits, and pieces of all sizes and forms.

- Metal Projects

Compared to woodworking, metalworking is a specialist talent that calls for various methods. It also needs various instruments, such as drill bits designed particularly to cut through metal. There are many various types of metal materials, similar to wood. Depending on your project, you could come across soft metals like copper, hard metals like stainless steel, or everything in between, including cast iron, aluminium, sheet steel, brass, bronze, and spring steel. Metal workers frequently use lubricants to cool their bits and lessen wear in order to counteract the heat produced by drilling resistance. While specialised oils frequently make the task simpler, water is sometimes adequate. Although the composition and coatings of carbide drills can be helpful when drilling metal, just as with wood, the type of drill bit used makes all the difference.

- Block and Concrete Projects

Special items include masonry blocks and concrete. Their characteristics differ significantly from those of metal and wood. As a result, if you want to drill a hole through their surfaces, you need bits that are specifically made for them. You could come across a variety of things made of concrete. Popular concrete products include pre-cast masonry blocks, roofing tiles, cement-fiberboard, and synthetic stone. Poured or cast-in-place concrete, the kind used for a patio or foundation, is also common. Any or all of these items could need to be drilled.

Finely crushed cement and larger-sized stone aggregates are combined to create concrete. There will always be a mix of hard and soft pockets when drilling into block and concrete materials. You could be installing a ledge on a masonry block wall or drilling a concrete foundation. If so, a carbide drill designed for the job is what you need. A concrete and block-specific electric drill is another tool you’ll need. Hammer drills and slotted drive shaft (SDS) drills are two popular types. Both drills employ a hammering action to cut and shatter concrete powder and aggregate.

Conclusion

For each application, selecting the appropriate carbide drill is crucial. The perfect decision may increase the life of your drill bits, whether it’s choosing the right bit for the substrate material, finding the right fit for the depth and diameter of the hole, or even the amount of effort required. In turn, this increases productivity by enabling you to do more tasks with each carbide drill.