A carbide insert is a tool used for accurately machining metal. Steel, carbon steel, cast iron, alloys at high temperatures, and non-ferrous metals with easy surface finishes can all be cut using this machine. You can easily replace the grips since many different types, sizes, shapes, and colors are available.

To keep your business running and competitive, it is essential to have the right equipment for metalworking. For different purposes, there’re different types of carbide inserts that are used. In the following article, you’ll find out all the applications of different kinds of inserts, including milling inserts, turning inserts, and aluminum inserts. Let’s dive in!

Types of Carbide Inserts

Carbide inserts are available in many types depending on your application requirements. Below is a list of some of the significant carbide inserts you are likely to encounter daily.

Turning Inserts

A turning tool body grips a replaceable insert attached to a lathe turret. Turning is typically done with a replaceable insert. Inserts for turning tools are manufactured using composite materials, coatings, and geometry features that provide high accuracy and high material removal rates.

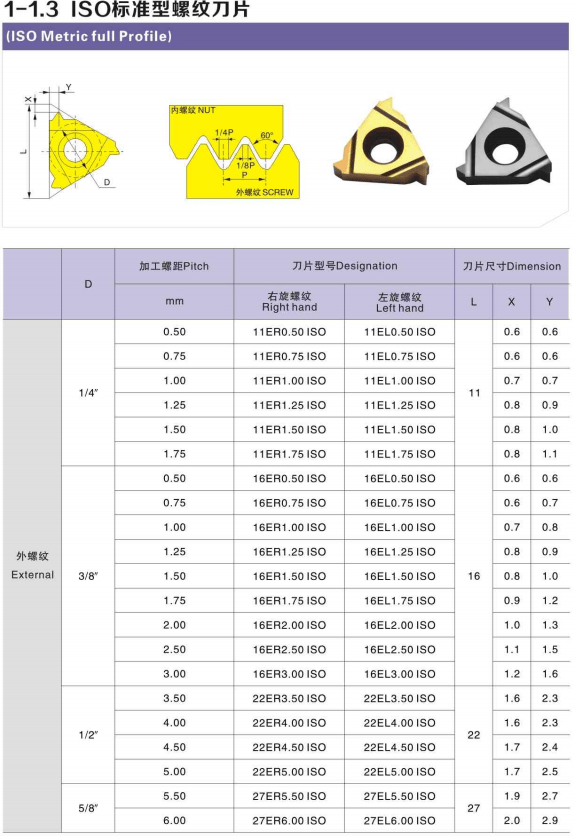

Threading carbide inserts

The carbide insert thread mill is the term used to describe a piece of cutting insert that is used to create an internal or external thread within a part. These are typically attached to a tool holder on a lathe or a turning center, where they are usually used with tools.

In addition to thread mills and thread rolling, thread inserts are another method for creating threads on a workpiece similar to thread milling. Putting these replaceable commodities in their proper places as replacements wear out is essential.

Based on the type of holder used, these inserts can cut grooves on both the outsides as well as the insides of a workpiece.

Among the many applications for which groove-making tools are relevant, there is a wide variety of hardware components of all types. These Carbide specialists specialize in determining the precise specifications required to suit the needs of each customer perfectly, regardless of whether they are parting off a smaller component or creating a deep groove with a large diameter. A Carbide insert can be grooved efficiently and expertly for extrusion grooving, internal grooving, face grooving, as well as parting. To maximize productivity and efficiency, you need to make sure that you choose the right tool. Every groove comes with its own set of challenges, no matter how wide or shallow it is. Additionally, every material used in the component’s manufacturing has its own properties and limitations. These three elements truly determine how the ideal tool should be designed, sized, and rated for the job.

Milling carbide inserts

The term milling insert refers to a piece of equipment that can be used to process materials such as steel and titanium without the fear of breaking the tool. The materials they help shape, they can straighten, shape, cut, and they can also cut metals such as steel, stainless steel, cast iron, non-ferrous materials, titanium, hardened steel, and plastic.

Drilling carbide inserts

With its high accuracy and high-performance indexable inserts, the Drilling and Hole Boring System is suitable for use on materials as diverse as aluminum and superalloys. With the drill body made of heat-treated steel that is very rigid, the nest for the insert is rigid and the flutes are straight, resulting in a long-term life for the insert and an efficient chip removal process.

Boring carbide inserts

Inserts made of cemented carbide are available in several sizes, shapes, and compositions that are used in various manufacturing methods on steels, cast iron, highly ferrous alloys, and nonferrous metals. In addition, machining metal parts more efficiently and with better finishes can be done when using carbide inserts. In addition to steel, stainless steel, hardened steel, cast iron, non-ferrous metals, titanium, and boring inserts are also good choices for applications.

How to choose the right insert

It would be best if you considered many factors to make the right choice regarding carbide inserts. Select insert geometry, insert grade, shape (nose angle), size, nose radius, and entry angle carefully to achieve reasonable chip control and machining performance.

- Choose insert geometry

A turning geometry can be divided into three basic types optimized for different operations: finishing, medium, and roughing.

Roughing

The combination of high feed rate and depth of cut results in an increased depth of cut. This is suitable for operations requiring the highest degree of edge security.

Medium

It includes operations that range from medium roughing to light roughing. You can choose something from a wide range of feed rates and depth of cut combinations.

Finishing

The combination of low feed rates and shallow depths of cut is ideal for shallow depths of cut. Applications that require low cutting force will benefit from this combination.

- Select the grade

Grades of inserts are selected primarily based on:

The ISO P, M, K, N, S, and H components

indicate the method (finishing, medium, roughing)

Manufacturing conditions (good, average, difficult)

- Choose an insert shape

I believe that you should choose the shape of the insert according to the amount of accessibility the tool requires at the point of entry. Selecting the smallest possible nose angle is recommended to provide insert strength and reliability. The margin for error has to be weighed against the variety of cuts made.

It requires more machine power and is more likely to vibrate more strongly when the nose angle is large. In addition to having a smaller nose angle, a minor cutting edge engagement can also make it more heat-sensitive as both of these things are weaker and more sensitive to heat.

Choosing a size

Adapting the insert size to the application’s requirements, as well as the space available for the cutting tool, should be considered.

The stability increases when the insert has a larger size. If you are going to be doing heavy machining, then the insert size should usually be over I.C. 25 mm (1 inch). In many cases, the size of a finished product can be reduced when it is finished.

Machining material

The purpose of carbide inserts is to enable the workpiece to be machined efficiently.

In this sense, it is of utmost importance to make sure that you choose the right tool for the purpose you have in mind. Several materials are available to us, including Aluminum, Bronze, Stainless steel, Cast Iron, and many others.

Types of carbide inserts for different Materials

Steel

Because the inserts are explicitly intended for use as inserts in steel surfacing operations. They can be run at faster clipping speeds and last longer than inserts used in various materials.

Cast Iron

The carbide insert for cast iron is made of abrasion-resistant carbide that will last longer, and then inserts are made of many different materials. Cast iron carbide inserts are made of an abrasion-resistant carbide, so their tool life is longer than inserts for other materials. Unlike the H series inserts, which can stick out from the holder to reach tight spaces on the workpiece with a negative rake, the K series inserts are the positive rake. Carbide inserts for cast inserts are commonly used for machining imperfectly round workpieces such as shafts with keyways since they were designed for semi-interrupted cutting conditions. You can install the inserts into the appropriate holder to begin using them.

Stainless Steel

Heat resistant and shaped for turning stainless steel specifically, these inserts will last longer than inserts for multiple materials.

Alloys

The inserts are not only heat-resistant and wear-resistant, but they also operate with outstanding performance when cutting super alloys such as titanium.

Multimaterial

With these premium turn-carbide inserts, your tool can cut a wide range of materials and is not required to change.

Non-ferrous Material

These premium inserts are ideal for cutting aluminum, copper brass, and other non-ferrous materials.

Factors that make Carbide Inserts useful

Cost

In addition to its high cost per unit, carbide is also very brittle, making it more susceptible to breaking and chipping when compared to other typical tool materials. Due to these factors, carbide cutting tips are often provided as small inserts within more extensive cutting tools that have steel hilts. The shank of the hilt is usually made of carbon, which is a more suitable material for the shank of the carbide cutting tip. As such, the carbide surface at the cutting interface is able to provide the benefits of using carbide without incurring the high costs and brittleness of making the complete tool from carbide. As with many of the modern lathe tools and endmills, most face mills these days have carbide inserts as well in them.

Coatings

Coatings are sometimes used in order to increase the lifetime of carbide inserts. Generally, coatings designed to increase a tool’s hardness or lubricity will also increase the tool’s lubricity. By coating a cutting tool, it will be possible for the cutting edge to pass cleanly through things without the material galling or sticking to it. Besides lowering the temperature associated with the cutting process, the coating will also increase the tool’s longevity by preventing the tools from getting stripped out. As a rule, the coating is deposited using either thermal CVD or mechanical PVD methods, both of which are usually done at lower temperatures, depending on the application.

Resistance

Carbide inserts exhibit hardness and wears resistance. They are harder than high-speed steel, making them ideal for cutting solutions. Coating such as TiN, TiCN, TiAIN, and AITiN extend the insert life by providing more resistance to wear.

Industry Applications of Carbide Inserts

Carbide inserts are in use since the 1920s. They are one of the most frequently used in the metal cutting world because they are not only efficient but also cost-effective. As discussed above, they come in various grade types and are highly durable. Also, they produce an excellent quality surface finish when used in cutting materials. There are a number of industries around the world in which carbide inserts are used. Here are a few applications listed.

Surgical tools

Carbide inserts are commonly used in the medical field. Physicians rely on durable and accurate tools for various medical procedures. The tools’ base is composed of titanium or stainless steel, and the tip is made up of tungsten carbide. The doctors rely on the precision of these inserts for the treatments and procedures.

Hard turning milling

Another application of carbide inserts is in the hard turning and milling. It is a flawless process for ceramics. A machining process makes a single carbide insert be in the cut for more extended periods. So, it is an excellent tool for maintaining high temperatures and making ceramic inserts perform optimally.

Jewelry making

Carbide inserts have various applications in the jewelry-making industry as well. They are used to shape jewelry items while making them. Tungsten material is just behind the diamond in terms of hardness, so highly useable in shaping wedding rings and other jewelry pieces.

Nuclear science industry

Tungsten carbide inserts are also used in the nuclear science industry as effective neutron reflectors. It was initially used during investigations in nuclear chain reactions, i.e., for weapon protection.

Automotive industry

They are used to remove more material during the machining process in the automotive industry. They are heat resistant, so you do not have to worry about the high temperatures. They also improve precision and control, hence producing more precise automotive parts. They also help enhance finishing and reduce waste, making them cost-effective.

Conclusion

To accurately and profitably machine the metal, you must select the right insert for your cutting. Properties like hardness, abrasion resistance, good strength and toughness, heat resistance, and corrosion resistance make carbide inserts useful for various industries nowadays. They are suitable for cutting steels or machining with low cutting loads to guarantee long tool life and accurate machining.