Adding a certain radius to a workpiece or performing finishing operations such as removing a burr or sharp edge are two common applications for a corner radius end mill. Before deciding on a tool, it is important to consider the several factors listed below. Suppose you choose the appropriate instrument, like corner radius end mill, wholesale corner radius end mill, and solid carbide corner radius end mills available at HUANA. As a result, you’ll have a sturdy instrument that has a long useable life and the dimensional attributes you want for your work. By making the wrong decision, you could end; you could end up with faulty parts and a poor experience.

How to Choose the Right Corner Radius End Mill:

- Corner Radius End Mill

The radius determines the constraints of the tool. When the diameters are increased, the speed at which the tool is operated can be decreased. However, the tool may be run at a higher speed when its radius is decreased due to the greater effective cutter radius. Because there is more material behind the radius of larger diameters, these have higher strength than smaller diameters that contain the same amount of material. When working in tight slots or holes, it’s possible that you’ll need a pilot with a smaller diameter for clearance. When machining an inside corner, using a pilot with a smaller diameter allows for tighter turns.

- Flared or Unflared Corner Rounder

When applying a wide radius to a component, there is a possibility that a step or an over-cut will be left on the workpiece. This may occur if the tool has not been entirely tuned in or if there is even a slight amount of runout or vibration. A very modest flare of 5 degrees on the pilot and shoulder merges the radius into the workpiece nicely and prevents an over-cut from being left behind.

corner radius end mill, wholesale corner radius end mill, and solid carbide corner radius end mills

A solid carbide corner radius end mill with a flared corner radius does not complete the radius, but it allows greater forgiveness. In addition to this, the tool produces a clean surface finish and does not need a second finishing operation to remove any markings that may have been left behind. A corner radius that is not flared leaves a full radius on the workpiece but takes additional set-up time to ensure that there are no steps.

- Front or Back

The position of the component you are machining should be the primary factor in determining whether you should use a Back Corner tool or a Corner radius end mill. When you need to put a radius on a portion of the component facing in the opposite direction as the spindle, you should use an end mill with a Back Corner radius. Even if the material could be rotated and a front Corner radius end mill utilized, doing so would result in an increase in both the total amount of time consumed and the cycle durations. When employing the usage of a Back Corner radius end mill, the correct clearance for the head diameter must be maintained as well as the use of the appropriate reach length. In the event that there is not enough clearance, the workpiece in question will need to be modified.

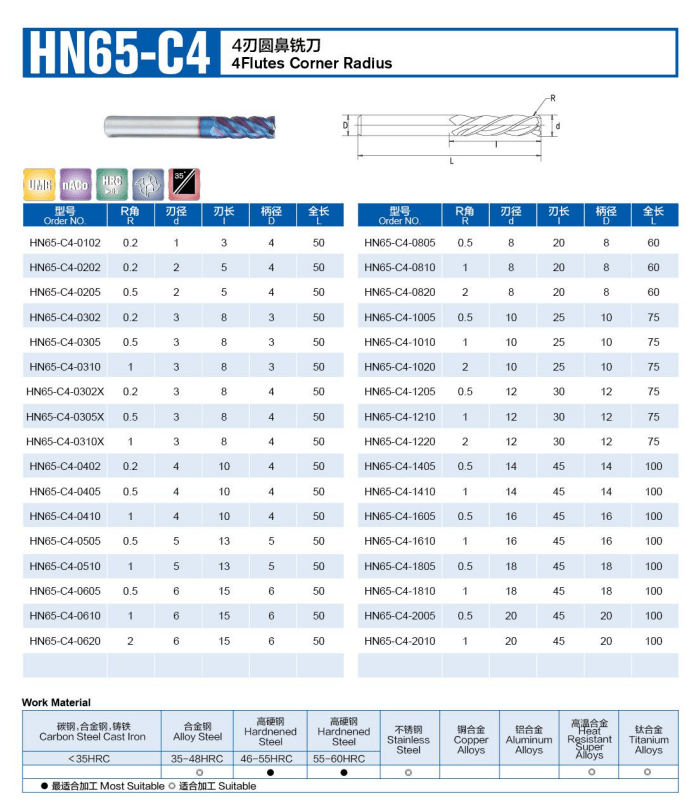

- Counting in Flute

These tools are often available in 2, 3, and 4 flute variations. Aluminum and other non-ferrous materials are typically cut with styles with two flutes, but three flutes are quickly becoming the more popular choice for these materials. Since these materials are softer than steel, it is possible to take a larger chip without negatively impacting the tool’s lifespan. When machining steels, you should select four flutes so that the wearer may be spread across numerous teeth, lengthening your tool’s life. Compared to tools with 2 or 3 flutes, models with four flutes may be operated at greater feed rates.

- Blending Of Corner Radius End Mill

The poor blending of corner radius end mills, solid carbide corner radius end mills, and wholesale corner radius end mills is one of the most prevalent faults that may be seen in the marketplace. This means that the radius is not tangent, which is often known as an “undercut” or “step.” It is of the utmost importance that a radius blend is performed flawlessly since any imperfections will be instantly conveyed to the component. This might lead to a variety of difficulties, including a poor finish or the formation of a line or ridge within the component itself. Because of this, we do not advise adding a radius to an end mill that has already been completed. It is recommended that the end mill be constructed with the required radius whenever possible.

Corner Radius End Mill Selection Summarized

The project at hand dictates which corner radius end mill works the best. If you want the greatest power and the most strength out of your tool, go for one that has the highest feasible pilot diameter. This is because a more effective cutter diameter tool takes less power since it has a larger diameter overall. Suppose the workpiece is permitted to have an incomplete radius. It is recommended to use a flared Corner Rounder for blending purposes since this allows for more leniency and can save time while setting up the machine. However, if this is not the case, a corner rounder that does not include flares should be used. The user’s choice is the primary factor to consider when selecting the appropriate number of flutes, as is so frequently the case. In general, softer materials call for a smaller number of flutes. When working with tougher materials, you should increase the number of flutes on your cutting tool.

Advantages Of Corner Radius End Mill High Quality

The term “high grade corner radius end mill” refers to the milling cutter, which can be fabricated from various materials, including cemented carbide. The end milling cutter may be loosely separated into integrated end milling cutter and end milling cutter with indexable inserts. Neither of these categories is excluded from the overall structure. In order to satisfy the requirements for processing posed by the two types of end mills, several companies have designed and manufactured a series of products featuring variable cutter head sizes, structural shapes, helix angles, and tooth numbers. These products are intended to meet the needs of the two types of end mills.

High-speed steel used to make up most of an integrated corner radius end mill construction in the past. It is becoming increasingly common to employ integrated cemented carbide end mills because of their superior hardness, resistance to wear, stiffness, and machining precision. The purpose of this is to enhance processing efficiency and quality. Because it is the complete carbide cemented, the cost is significantly higher, particularly for the big and thick diameter. Because of this, the end milling cutter, much like the turning tool and the face milling cutter, is fitted with indexable inserts so that it may fulfill the processing requirements. End milling cutters with wide applications may be fabricated using indexable inserts in several configurations.

Purpose of High-Quality Corner Radius End Mill:

The CNC machining center and the CNC engraving machine are primary applications for high-quality corner radius end mills. It is also possible to put it on a regular milling machine to handle some difficult and straightforward materials requiring heat treatment.

- Corner radius end mill: A corner radius end mill is a type of milling cutter used on horizontal milling machines to manufacture planes. The milling cutter features a set of teeth arranged in a spiral pattern or a straight line around its perimeter. Depending on the tooth form, these teeth can either be straight or spiral. It is possible to classify them as either coarse or fine teeth based on the number of teeth they have. Due to the limited number of teeth, strong tooth strength, and big chip holding area of the coarse helical gear milling cutter, it is best suited for rough machining. On the other hand, the fine helical gear milling cutter is best suited for finish machining.

- Corner radius face milling cutter is a tool that may be utilized for cutting planes on the gantry, end face, and vertical milling machines. There are coarse teeth and fine teeth, and cutter teeth located on the end face and the perimeter of the tool. There are three distinct structure varieties, namely the integral type, the inlaid type, and the indexable type.

- Corner radius end mill: It is utilized for the process of machining grooves as well as step surfaces. Because they are located on the circumferential and end face, the cutter teeth cannot feed in the axial direction when the tool is being used. The end milling cutter can feed the axially when it has an end tooth that passes through the center of the cutter.

- Corner radius three side edge milling cutter: This three side edge milling cutter is utilized to process a wide variety of groove and step surfaces. In addition to having teeth around the circumference, it has teeth on each side as well.

- Corner radius end mill angle milling cutter: This particular milling cutter is utilized to cut grooves at a certain angle. The two varieties of this tool are the single-angle milling cutter and the double-angle milling cutter.

- A Corner Radius Saw Blade Milling Cutter: This milling cutter is used to cut deep grooves and workpieces, and it has more cutter teeth on the circumference than the other milling cutters. There are offset angles of 15′ and 1′ on both sides of the cutter teeth to lessen the amount of friction during the milling process. In addition, there is a T-shaped groove milling cutter, a keyway milling cutter, a dovetail groove milling cutter, and a variety of other forming milling cutters.

The Benefits of Using HUANA Corner Radius End Mills

- The development of a coolant that extends the useful life of tools and inserts

- Nine millimeters to one hundred millimeters is the diameter range.

- Work of the highest quality and most exacting standards

- cutting a surface while also machining a radius using the same holder

- Complete inventory together with detailed specifications for expedited shipping

- Have an immediate impact on the level of precision that can be attained in the machining process

- A fully ground spiral groove has an elegant spiral groove, a huge chip removal area, the elimination of knife sticking, and a significant increase in production effectiveness.

- Simple to use: the chamfering pattern is simpler to clamp, and it helps to absorb shock while the milling operation is being carried out.

- A sharp cutting edge has a longer useful life.

- Nano coating increases the material’s toughness while also enhancing its surface polish, ambiance, and durability.

Conclusion

At HUANA, corner radius end mill, wholesale corner radius end mill and solid carbide corner radius end mills are available in various forms and dimensions; however, this article has focused on the Corner Radius End Mill. Several different reasons exist for why a corner radius end mill would be the best tool to use, but one of the most prevalent explanations is that the tool is stronger. The use of a radius can protect the corners of an object from being chipped or broken. When it comes to end mills, the corner is the most vulnerable section of the instrument. Another typical justification for employing a radius end mill is that the final part imposes such a need or specification. A radius can be one of several different diameters determined by the cutting diameter.

As a result of reading this article, do you now have a basic understanding of the benefits of using a corner radius endmill and how to select the appropriate one? I really hope that this file can contribute in some little way. Please don’t hesitate to get in touch with HUANA if you have any more questions!