-

“Understanding the Different Types of CNC Cutting Tools”

- In the intricate world of machining, precision is paramount, and at the heart of precision lies CNC cutting tools. These technological marvels revolutionize manufacturing processes by combining cutting-edge design with impeccable accuracy. In this exploration, we’ll journey through the basics of CNC cutting tools, delve into the realm of DNMG inserts, uncover their advantages, and illuminate their applications across diverse industries.

Unveiling CNC Cutting Tools: Architects of Precision Machining

CNC cutting tools are the architects of modern machining, orchestrating intricate operations with a blend of technology and finesse. As pivotal components of the machining process, these tools are designed for unparalleled precision, efficiency, and consistency. In the realm of CNC cutting tools, one class shines exceptionally bright: DNMG inserts.

DNMG Inserts: Defining Precision in Machining

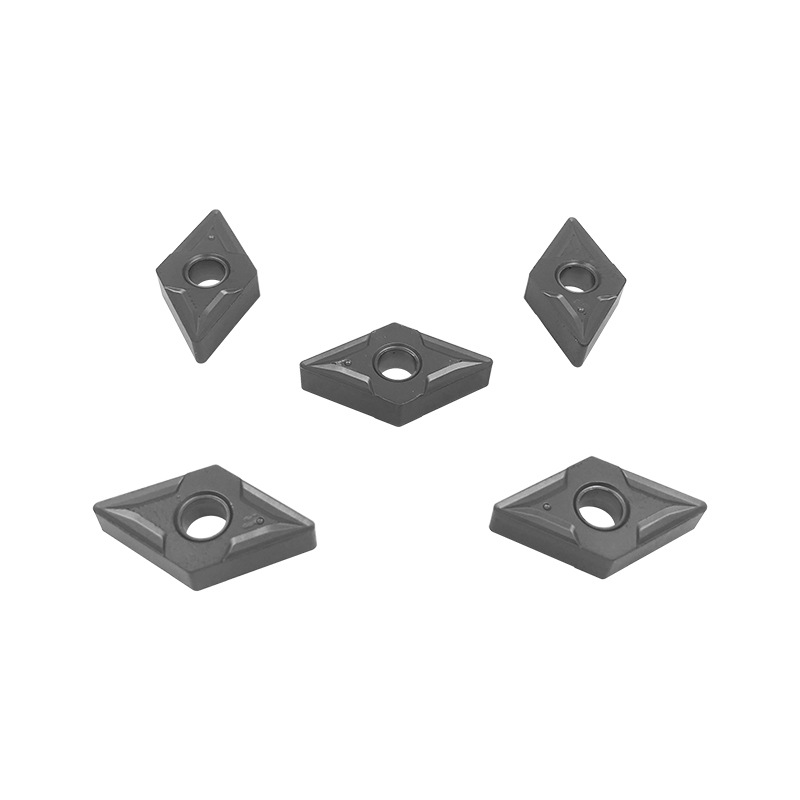

DNMG inserts stand tall among CNC cutting tools, celebrated for their distinctive form and versatile function. The nomenclature “DNMG” signifies their geometry, capturing the essence of their design. These inserts are crafted to excel in turning and machining tasks, elegantly shaping raw materials into refined products.

Unpacking the Advantages of DNMG Inserts: Where Precision Meets Innovation

- Versatility Unleashed: DNMG inserts transcend material boundaries, demonstrating their prowess across industries and applications.

- Enhanced Performance: The precision-engineered geometry of DNMG inserts ensures optimal chip control and superior surface finish.

- Cost-Effective Excellence: By prolonging tool life and optimizing machining processes, DNMG inserts contribute to cost-efficiency.

- Reduced Downtime: DNMG inserts’ reliability translates to minimized tool changes, maximizing uptime and productivity.

Applications Across Industries: Precision for Every Sector

The impact of DNMG inserts reverberates across industries, revolutionizing manufacturing processes:

- Automotive: Precision-machined components drive the automotive sector’s efficiency and quality, thanks to DNMG inserts.

- Aerospace: From intricate parts to aerospace marvels, DNMG inserts play a pivotal role in shaping the future of flight.

- Energy: DNMG inserts ensure precision in energy sector components, from turbine blades to oil and gas equipment.

- Medical: In the medical world, DNMG inserts help craft precision instruments, elevating healthcare standards.

Embracing Precision with CNC Cutting Tools and DNMG Inserts

In a world that demands perfection, CNC cutting tools and DNMG inserts stand as the torchbearers of precision and innovation. This journey through the world of machining has unveiled the foundation of CNC cutting tools, spotlighting the brilliance of DNMG inserts. With each turn of the lathe and every precision cut, these tools redefine what’s achievable, fueling progress across industries and embodying the essence of precision machining.

- In the intricate world of machining, precision is paramount, and at the heart of precision lies CNC cutting tools. These technological marvels revolutionize manufacturing processes by combining cutting-edge design with impeccable accuracy. In this exploration, we’ll journey through the basics of CNC cutting tools, delve into the realm of DNMG inserts, uncover their advantages, and illuminate their applications across diverse industries.

-

“Choosing the Right Cutting Tools for Precision Machining”

- Selecting Cutting Tools for Precision Work: Navigating Excellence

In the intricate realm of precision machining, the choice of cutting tools is nothing short of pivotal. The path to precision begins with selecting the right tools that align with the intricacies of the task at hand. This exploration delves into the significance of making informed choices, offers a comprehensive overview of DNMG inserts, outlines key factors for choosing inserts, and sheds light on their profound impact on precision machining.

The Significance of Informed Choices: Precision Starts Here

The cornerstone of precision machining lies in the selection of appropriate cutting tools. The tools you choose define the outcome, influencing efficiency, accuracy, and the overall quality of the end product. The journey towards precision commences with the conscious decision to align your work with tools tailored for the task.

Unveiling DNMG Inserts: The Precision Enablers

At the heart of precision machining, DNMG inserts emerge as true enablers. DNMG inserts embody meticulous engineering, catering to a range of applications and materials. Their distinct design sets the stage for precision, enabling machinists to achieve remarkable accuracy in their work.

Key Factors for Choosing Inserts: Navigating the Decision

- Material Compatibility: The choice of inserts hinges on the materials you work with. DNMG inserts’ versatility covers a spectrum of materials, ensuring your tool is aligned with your task.

- Geometry and Chip Control: The design of DNMG inserts includes chip breakers that optimize chip control, leading to efficient operations and finer finishes.

- Cutting Conditions: Considering factors like cutting speed and feed rates is crucial. DNMG inserts’ design factors in various cutting conditions, ensuring consistent performance.

- Tool Life and Durability: DNMG inserts’ robust construction contributes to prolonged tool life, reducing the frequency of tool changes and enhancing overall efficiency.

Precision Machining Redefined: DNMG Inserts at Play

The impact of choosing the right insert for precision work extends far beyond the immediate task. Precision machining reverberates through industries, contributing to higher quality products, streamlined processes, and reduced wastage. DNMG inserts, with their precise design and compatibility, become integral to achieving these goals.

Elevating Precision with DNMG Inserts

In the intricate dance of precision machining, the choice of cutting tools plays a starring role. DNMG inserts, with their versatile design and compatibility, offer a gateway to precision that transcends industries. By aligning your work with the principles of informed tool selection, you pave the way for accuracy, efficiency, and excellence. With DNMG inserts as your ally, precision machining becomes more than a goal – it becomes a reality that you craft with every meticulous cut.

- Selecting Cutting Tools for Precision Work: Navigating Excellence

-

“A Comprehensive Guide to CNC Inserts and Their Applications”

- In the realm of precision machining, the key to unlocking optimal performance lies in the mastery of CNC inserts. These versatile tools are the linchpin of efficient machining processes, shaping raw materials into refined products with unparalleled accuracy. This journey takes you through an overview of CNC inserts, delves deep into the mechanics of DNMG inserts, unveils their applications across industries, and equips you with invaluable tips for optimizing their performance.

Embarking on the CNC Insert Odyssey: A Glimpse into Versatility

CNC inserts form the bedrock of precision machining, revolutionizing the way materials are shaped and transformed. These inserts, designed with meticulous engineering, streamline cutting operations by optimizing tool life, chip control, and surface finish. Among the distinguished class of CNC inserts, DNMG inserts shine as true exemplars of precision.

DNMG Inserts: Precision in Every Detail

The intricate design of DNMG inserts elevates precision machining to an art form. DNMG inserts, bearing their distinctive geometry, are crafted to excel in turning and machining tasks. Their versatility spans a spectrum of materials and cutting conditions, making them a reliable companion in diverse industrial landscapes.

Applications Across Industries: From Innovation to Reality

DNMG inserts transcend industry boundaries, contributing to precision and efficiency in various sectors:

- Automotive: From engine components to intricate parts, DNMG inserts are instrumental in crafting high-performance automotive elements.

- Aerospace: The aerospace sector benefits from DNMG inserts’ precision, ensuring the creation of components that meet the highest standards.

- Energy: In energy-related applications, from turbine blades to oil and gas equipment, DNMG inserts guarantee accuracy and quality.

- Medical: DNMG inserts play a pivotal role in shaping intricate medical instruments, safeguarding precision in healthcare.

Mastering DNMG Insert Performance: Gems of Wisdom

- Optimal Feed Rates and Speeds: Adjusting feed rates and cutting speeds in accordance with the material and insert design enhances efficiency and surface finish.

- Precision in Chip Control: DNMG inserts’ chip breakers ensure smooth chip evacuation, preventing tool damage and prolonging tool life.

- Proper Toolholder Alignment: Ensuring accurate insert positioning in the toolholder minimizes vibrations and guarantees precision.

- Utilizing Advanced Coatings: Leveraging specialized coatings enhances wear resistance and extends the life of DNMG inserts.

Crafting Excellence with DNMG Inserts

In the intricate ballet of precision machining, CNC inserts take center stage, and DNMG inserts emerge as the stars that shine the brightest. As you delve into the nuances of CNC inserts and their applications, you’re empowered with the knowledge to drive innovation and precision in your endeavors. By optimizing DNMG insert performance, you elevate machining to an art form that embodies accuracy, efficiency, and excellence. With DNMG inserts as your allies, you’re poised to sculpt the future of manufacturing with each meticulous cut and every finely crafted component.

- In the realm of precision machining, the key to unlocking optimal performance lies in the mastery of CNC inserts. These versatile tools are the linchpin of efficient machining processes, shaping raw materials into refined products with unparalleled accuracy. This journey takes you through an overview of CNC inserts, delves deep into the mechanics of DNMG inserts, unveils their applications across industries, and equips you with invaluable tips for optimizing their performance.

-

“Maximizing Efficiency with CNC Milling Cutters: A Complete Guide”

- Mastering Efficiency and Quality with CNC Milling Cutters: A Comprehensive Guide

In the realm of precision manufacturing, CNC milling cutters stand as the pinnacle of machining excellence. These tools, akin to sculptors’ chisels, shape raw materials into intricate works of art with precision and finesse. This guide is dedicated to the world of CNC milling cutters, spotlighting the significance of DNMG inserts, unraveling the secrets to optimizing efficiency and cost-effectiveness, and unveiling strategies to elevate product quality in machining processes.

Crafting Excellence with CNC Milling Cutters: Precision Personified

CNC milling cutters are the architects of precision, transforming raw materials into refined components. These tools embrace technology, geometry, and mechanics to orchestrate intricate machining operations that meet exacting standards. In this exploration, we delve into the profound impact of CNC milling cutters and how they redefine precision in machining.

DNMG Inserts: Elevating CNC Milling Precision

At the heart of CNC milling cutters’ brilliance lies the power of inserts like DNMG. These inserts are the virtuosos that dictate the precision of each cut, turning a symphony of mechanics into a harmonious masterpiece. DNMG inserts, with their distinct geometry and versatility, exemplify precision that spans a spectrum of materials and industries.

Enhancing Efficiency and Cost-Effectiveness: The Path to Mastery

- Optimize Toolpath Strategies: Tailoring toolpath strategies to minimize unnecessary movements and maximize cutting efficiency.

- Material Selection: Choosing the right materials for both the workpiece and tool ensures optimal performance and prolonged tool life.

- High-Speed Machining: Embracing high-speed machining techniques reduces cycle times and boosts overall efficiency.

- Coolant and Lubrication: Implementing appropriate coolant and lubrication techniques enhances cutting performance and reduces tool wear.

Elevating Product Quality: Where Precision Meets Excellence

- Toolholder Rigidity: A rigid toolholder minimizes vibrations, contributing to better surface finish and dimensional accuracy.

- Balancing Speed and Feed Rates: Striking the right balance between cutting speed and feed rate results in optimal surface finish and longer tool life.

- Inspection and Measurement: Regular inspection and measurement of finished products ensure adherence to specifications and enhance overall quality.

- Advanced Tool Coatings: Leveraging advanced coatings on CNC milling cutters and inserts enhances wear resistance and reduces friction.

Unveiling Excellence in CNC Milling Cutters

In the ever-evolving landscape of precision manufacturing, CNC milling cutters reign supreme, embodying the essence of precision and artistry. The fusion of technology and mechanics, guided by the precision of DNMG inserts, sets the stage for machining excellence. By mastering efficiency, cost-effectiveness, and product quality, professionals unlock the power to sculpt components that seamlessly merge precision with perfection. With CNC milling cutters as their tools of choice, professionals forge the future of manufacturing – one meticulous cut at a time.

- Mastering Efficiency and Quality with CNC Milling Cutters: A Comprehensive Guide

-

“Improving Manufacturing Processes with Advanced CNC Cutting Tools”

- In the realm of modern manufacturing, advancements in technology are redefining the boundaries of precision and efficiency. Among these advancements, advanced CNC cutting tools stand as trailblazers, propelling industries into new realms of excellence. This exploration is dedicated to unveiling the world of advanced CNC cutting tools, spotlighting DNMG inserts as a prime example, deciphering their role in refining manufacturing processes, and illuminating their profound impact on the final products.

Entering the Era of Advanced CNC Cutting Tools: A New Frontier of Precision

The manufacturing landscape is undergoing a paradigm shift, where advanced CNC cutting tools take center stage. These tools, infused with innovation and engineering prowess, transcend conventional boundaries to set new standards in precision and efficiency. As we embark on this journey, we delve into the core of advanced CNC cutting tools and their potential to redefine manufacturing norms.

DNMG Inserts: Exemplifying Precision and Versatility

Among the vanguard of advanced CNC cutting tools, DNMG inserts emerge as torchbearers of precision and versatility. DNMG inserts, with their intricate geometry and adaptable design, exemplify the fusion of art and technology. These inserts transcend traditional boundaries, enhancing machining processes across industries and materials, and paving the way for the future of manufacturing.

Enhancing Manufacturing Processes: DNMG Inserts as Catalysts for Progress

- Efficiency Redefined: DNMG inserts optimize cutting operations, reducing cycle times, and enhancing throughput, thereby elevating manufacturing efficiency.

- Quality Assurance: Precise tool design and chip control mechanisms offered by DNMG inserts contribute to consistent and impeccable product quality.

- Cost-Effectiveness: The efficiency and reliability of DNMG inserts translate to reduced downtime, lower tooling costs, and enhanced overall cost-effectiveness.

- Reducing Waste: DNMG inserts’ precision minimizes material wastage, aligning with sustainable manufacturing practices and economic resource management.

Impact on Final Products: Where Excellence Takes Shape

The journey of advanced CNC cutting tools, led by DNMG inserts, culminates in the realm of final products. The meticulous craftsmanship and precision instilled by these tools reverberate through the manufacturing process, leaving an indelible mark on the finished components.

Embracing the Future of Manufacturing with DNMG Inserts

In the ever-evolving landscape of manufacturing, advanced CNC cutting tools emerge as catalysts of transformation. DNMG inserts, with their precision, adaptability, and efficiency, are leading the charge towards a new era of manufacturing excellence. By embracing the potential of advanced tools, manufacturers embark on a journey where precision, efficiency, and innovation intersect to shape the products that define our world. With DNMG inserts guiding their path, manufacturers carve a future that seamlessly blends technology, craftsmanship, and progress.

- In the realm of modern manufacturing, advancements in technology are redefining the boundaries of precision and efficiency. Among these advancements, advanced CNC cutting tools stand as trailblazers, propelling industries into new realms of excellence. This exploration is dedicated to unveiling the world of advanced CNC cutting tools, spotlighting DNMG inserts as a prime example, deciphering their role in refining manufacturing processes, and illuminating their profound impact on the final products.

Based on HUANATOOLS——Guide to DNMG Inserts

At HUANA Tools, we specialize in crafting tungsten steel CNC cutting tools that redefine industry standards. As CNC cutting tools take center stage in modern manufacturing, DNMG inserts emerge as the epitome of precision, and here’s why.

Understanding DNMG Inserts

Our DNMG inserts are more than tools – they are the embodiment of precision. Engineered with meticulous composition, design, and variations, these inserts transform raw materials into masterpieces. Their distinct features make them the ideal choice for precision machining, ensuring consistent and impeccable results.

Applications and Benefits

Industries seeking unparalleled performance turn to DNMG inserts. From automotive to aerospace, these inserts excel across sectors, enhancing efficiency, and cost-effectiveness. Their advantages are apparent – superior performance, efficiency, and the promise of cost optimization.

Choosing the Right DNMG Inserts

Selecting the perfect insert is a blend of art and science. Our experts understand the factors that matter. Aligning insert choice with specific machining requirements ensures that your projects meet the highest standards.

Optimizing Performance

Maximizing DNMG insert performance is an art we’ve mastered. Our tips lead to precision, stability, and extended tool life, enabling you to craft components that stand the test of time.

HUANA’s Commitment to Quality

Quality is non-negotiable at HUANA. Competitive pricing meets rigorous quality assurance. Our collaborations with reputable suppliers and comprehensive inspections ensure excellence in every piece.

Real-world Applications

Intrigued by the real-world impact of DNMG inserts? Our case studies showcase their success across diverse industries. Quality, affordability, and performance converge to create results that speak volumes.

Navigating Global Markets

Across borders, HUANA’s reputation shines. With international presence and reliable sea exports, we accommodate large-scale orders with utmost efficiency.

Precision Redefined

At HUANA Tools, we sculpt precision with every tool we craft. DNMG inserts are our pride, and their precision is your competitive edge. Join us in revolutionizing manufacturing – where quality, innovation, and performance converge.