A Comprehensive Guide About Solid Carbide Bottom Engraving Bits

Have you given any thought to the possibility of trying your hand at engraving? Practice, self-assurance, and patience are the keys to success when it comes to engraving, regardless of whether you want to enliven boring household items or create a unique present for someone important. In this helpful guide to engraving with Solid Carbide Bottom Engraving Bits, we cover everything you need to know to get started engraving with Huana Solid Carbide Bottom Engraving Bits as soon as possible.

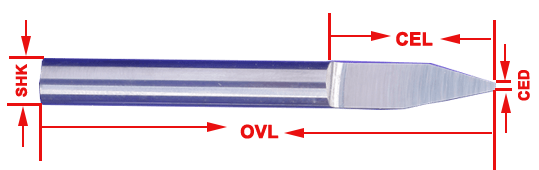

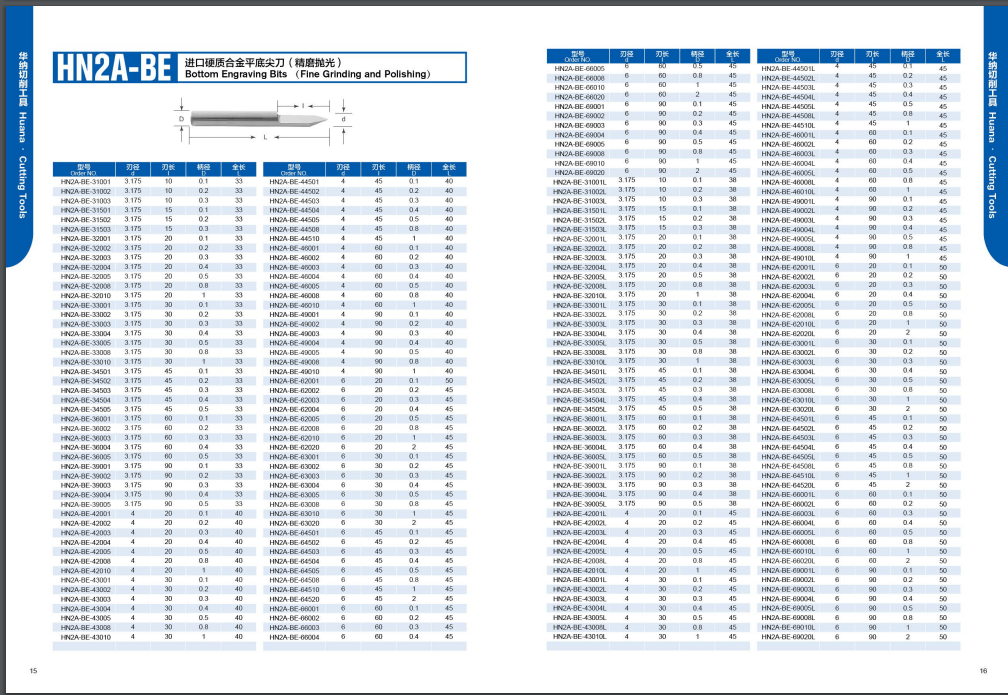

The carbide used in the construction of solid carbide bottom engraving bits is of the highest possible grade. Huana have a wealth of expertise in the production and distribution of high-quality Solid Carbide Bottom Engraving Bits. Versatile bottom cutting engravers ground from solid carbide. The solid carbide bottom engraving bits are available in a wide range of angles and tip widths so that they may be used for virtually any engraving job. When used on most materials, including Double-color board, ABS Board, Acrylic, PVC, Aluminum, copper, and iron, Huana solid carbide bottom engraving bits will produce clean cutting. On request, we may create angles and tip widths that are unique to your needs.

Application of Solid Carbide Bottom Engraving Bits

- Double color board

The double-color board is a type of board that is specifically used for engraving and is comprised of two layers of different colors. Solid carbide bottom engraving bits are utilized for the purposes of cutting, shaping, and molding the double-color boards. Huana offers the highest quality solid carbide bottom engraving bits on the market, which are suitable for use on double-color boards.

- ABS board

Bottom engraving bits made of solid carbide are engineered to work with the characteristics of particular materials, which results in the cleanest cuts possible. When cutting ABS board using Huana solid carbide bottom engraving bits, despite the fact that these bits are more expensive, if they are used correctly, they will last longer and offer a superior finish owing to the morphologies and geometry of the cutters. Flutes cutters that have been polished allow for improved chip removal and, as a result, increase the life of your equipment.

- Acrylic

Acrylic is a wonderful material to work with since it is resilient and flexible. It is an excellent alternative to glass since it weighs just one-half as much and possesses an exceptional resilience to impact. Although it may be purchased in any colour conceivable, acrylic should be avoided in locations that experience high levels of heat. Solid carbide bottom engraving bits are simple to use on acrylic and have the ability to cleanly cut through acrylic with little effort.

When cutting acrylic with an engraving bit, one of the most typical issues that arises is that the material warms up, which causes the edges to partially melt and then reform, either bonding back together or providing you with a rough edge. In order to prevent this from happening, you will need to shorten the amount of time that the solid carbide bottom engraving bit is in contact with the acrylic. Additionally, you should utilize Huana solid carbide bottom engraving bits to assist you in achieving the finest possible finish.

- PVC

PVC, or polyvinyl chloride, is a kind of plastic that is both inexpensive and strong, making it an excellent choice for components that must maintain their low weight. Along with having good resistance to corrosion, flame, and water, it also has a high level of machinability to near tolerances. PVC also possesses excellent toughness, impact resistance, and strength properties. PVC may be readily cut with Huana solid carbide bottom engraving bits, and the finish they produce is of the highest quality. Using Huana solid carbide bottom engraving bits, it is possible to mill foamed PVC as well as rigid PVC to a satisfactory level.

- Aluminium

Aluminum is one of the materials that is machined the most frequently since most forms of the material have good machinability. As a result, aluminum is one of the materials that is most frequently utilized in manufacturing. Because of this, there is often a lot of rivalry in the market for aluminum machining. Therefore, Huana has developed solid carbide bottom engraving bits constructed of solid carbide for aluminum. Aluminum is a lightweight material that can be worked easily and is very easy to shape. You may find components created from this material in virtually every sector of the economy. In addition, due to its low cost and high flexibility, aluminum has emerged as a material of choice for the construction of prototypes.

Cast and wrought are the two primary varieties of aluminum that may be purchased. The alloys that are made from wrought aluminum are often more costly, stronger, and contain a lesser amount of elements from the outside world. In addition to being more resistant to heat, wrought aluminum also offers a greater level of machinability than cast aluminum. In order to facilitate the process for the Huana, solid carbide bottom engraving bits have been developed. These bits can be used on aluminum and provide the best possible finish. Bottom engraving bits made of solid carbide from Huana are capable of producing a good finish when cutting either type of aluminum.

- Copper

Copper is a great conductor of both heat and electricity; as a result, it is a suitable metal for use in a variety of electronic components, where its heat dissipation properties and excellent electric conductivity make it a perfect choice. However, slicing copper may be an absolute misery. Copper is a difficult material to mill due to its ductile nature, fluidity, and hardness, all of which combine to make it a problematic material. Because of its great ductility, plasticity, and hardness, copper in its purest form is a challenging metal to manufacture. Machining copper with a Huana solid carbide bottom engraving bit yields good results, however the finished product has a few burrs around the surface. Copper can have a higher quality surface finish if it is engraved using a solid carbide bottom engraving bit that has a shallow depth of cut.

- Iron

Cast iron may be machined with Huana solid carbide bottom engraving bits into completed components just as quickly as most types of steel, but with less wear on the tools required for the process. It is an extremely reliable substance that is resistant to wear and is an excellent material for absorbing vibrations. Hand milling is still beneficial in some circumstances, despite the increased precision, accuracy, and output rates offered by Huana solid carbide bottom engraving bits.

How Do You Get Started With Huana Solid Carbide Bottom Engraving Bits?

The pieces themselves are reasonably priced. Rather than forcing you to buy them all or figure it out on your own, this guide will show you how to utilize and select engraving bits to save time and money.

Select the appropriate engraving bits

Bottom engraving bit made of solid carbide by Huana. Huana solid carbide bottom engraving bits are versatile and suitable for engraving, contouring, hollowing, and grooving. Huana solid carbide bottom engraving bits are ideal for engraving materials such as ABS board, PVC, and aluminium.

Engraving Cutters are also suitable for detail work, particularly when the material is not too hard. They are equally effective on wood and plastic as they are on softer metals. Huana solid carbide bottom engraving bits are particularly suited for fine-detail work. Because the bits are composed of solid carbide, they are ideal for engraving tougher materials.

Select the appropriate accessories for your engraving job

Consider attachments to be the items that make your project go a little more smoothly. The Flexible Shaft mounts in seconds to your solid carbide bottom engraving bit, and the 127mm cable adds comfort and flexibility while operation. The weight of the solid carbide bottom engraving bit has been removed, making it ideal for engraving a wine glass, for example. The Detailer’s Grip is another useful accessory that fits any rotary tool with a threaded nose piece. It shifts the weight of the tool to your palm for enhanced tool balance and control, which is especially beneficial for doing precision work like engraving, carving, etching, and polishing.

To begin engraving, choose a material

When you’re just starting out with engraving, go for something softer. Why? They simply make it simpler for you to get the desired amount of control while using your Huana solid carbide bottom engraving bit, making them ideal for novices. Brass and copper are the softest metals (so save that titanium watch for when you’re a little more experienced!). Leather, polymers, and wood are examples of soft materials.

Pay attention to the SHAPE

Material isn’t the only crucial thing to consider when selecting an object to begin engraving with Huana solid carbide bottom engraving bits. Consider the surface contour as well as the soft materials (such as soft metals, leather, or wood). What is the ideal shape to start with? Anything that is flat. You don’t have to worry about angles or constantly repositioning the object or instrument on flat surfaces. You only need to focus on getting acclimated to how the tool feels when engraving – which is precisely how it should be when you’re first starting off.

Take the necessary precautions

You’re probably eager to get started now that you’ve obtained the correct engraving bit for the job and a ready-to-engrave surface. But first, let’s go through some safety precautions. Leather gloves will not only protect your hands from cuts and scratches, but they will also be more resistant to wear and tear. Goggles and a dust mask are also recommended for engraving since you don’t want to breathe in tiny glass or metal fragments (or getting it anywhere near your eyes). And if the antique serving platter you’re eyeing exhibits any indications of corrosion, put down the engraving tool. Rust particles are hazardous to one’s health.

Get everything ready that has to be done

Check that the material you’re going to engrave is clean and dry before you begin. Not only should all traces of grease and cleaning solutions be properly removed so that you can see clearly, but also so that there are no issues at the stage where the item is transferred. Wood engraving? Confirm that it has not been treated in any way. If you wish to engrave on wood that has been painted in the past, you will need to sand it down and clean it with a damp cloth before you begin. You may begin using the Huana solid carbide bottom engraving bit once the surface has been well cleaned and dried.

Construct a pattern with the piece of material

Using a printed pattern as a guide to transcribe is an excellent method for getting started. Even while you may engrave freehand, using a template as a guide as you work is a far more efficient method to begin. When transferring a design from one surface of metal to another, carbon paper is the medium of choice. Placing the paper on top of the metal surface, arranging the design so that it fits, and then tracing it with a pencil are the only steps involved. It is much simpler to engrave PVC; simply position the design underneath the material, and you will be able to see it through the material and use it as a guide.

Conclusion

When it comes to the actual process of engraving, using solid carbide bottom engraving bits from Huana is the more convenient option. Because it is a movement that you are already accustomed with, it stands to reason that this familiarity bestows upon you the highest amount of self-assurance possible when it comes to the control that you exercise over your engraving tools. When you are just starting out in engraving, it is quite typical for things to take a little bit of time to go according to plan. If you put in some practice, with patience you learn, and keep it up, not only will your engraving talents improve but also your self-confidence. HUANA is the place to go without question if you want to get solid carbide bottom engraving bits made of solid carbide of a high grade.