Carbide drill bit manufacturing implies having specific knowledge of cylindrical grinding. It is a manufacturing process that forms and sharpens cutting tools with amazing precision. Most manufacturers have a problem choosing the correct equipment to use in their carbide drill production requirements.

Cylindrical grinding Carbide blanks are cylindrical-shaped grinding products that are manufactured into cutting tools. Material is removed during the process, but the final dimensions and surface finishes are preserved. These are the methods that professional manufacturers use to produce high-quality carbide drill bits that meet industrial standards.

What are Carbide Drill Bits and Cylindrical Grinding?

Carbide drill bits are the ultimate in cutting tool technology. These tools have tungsten carbide powder with cobalt binders that form very hard and wear-resistant cutting edges. Its production process entails the strict handling of all production details.

When it comes to carbide drill bits, cylindrical grinding is the major way of shaping them. It is a substance-removal technique that employs abrasive wheels on turning workpieces. The process enables the manufacturer to achieve tolerances as close as 0.0001 inches and maintain consistent surface appearances.

Cylindrical grinding, coupled with carbide materials, has produced tools with a remarkably long lifespan compared to conventional steel bits. Manufacturers of these high-quality cutting tools invest a lot in specialized grinding machines to manufacture these tools. The operation is sensitive to the selection of wheels, cutting speeds, and coolants.

The Cylindrical Grinding Process for Carbide Tools

The process of cylindrical grinding of carbide drill bits consists of some separate operations. The procedure starts with the mounting of the carbide blank in special fixtures that provide perfect alignment. The operators should be keen when placing every piece to ensure concentricity during the grinding cycle.

The grinding wheel is made to touch the rotating carbide blank at well-regulated speeds. Carbide materials are most suitable with diamond wheels since they stay longer on the cutting action compared to conventional abrasives. The grinding process removes material while simultaneously creating the requested drill geometry.

The coolant systems are very essential in the carbide drill grinding processes. During the grinding process, a significant amount of heat is generated and can damage the carbide materials if not properly managed. The work area is chilled, and high-pressure fluid circulates to remove heat and grinding waste. In newer systems, synthetic coolants are used,, which have both better cooling and lubricating capabilities.

Key Process Parameters:

- Wheel speed: 1,800-3,600 surface feet per minute.

- Speed of work: 50-200 revolutions/minute

- Feed rates: 0.001-0.010 inch per revolution

- Depth of grinding: 0.0005- 0.005 inches per pass

- Coolant flow: 5- 20 gallons /minute minimum

Quality control measures check every grinding. Precision measuring tools are used by operators to check dimensions during the process. Statistical process control allows for keeping the quality of production runs at a regular level.

High Precision Cylindrical Grinding Machine Selection

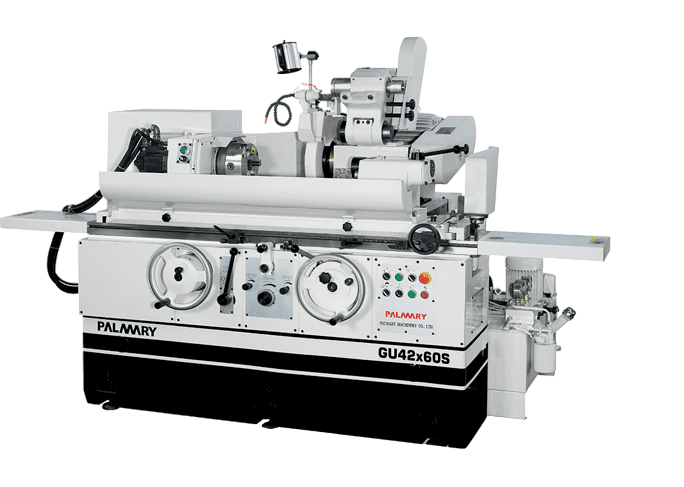

Modern carbide drill production depends upon high-precision cylindrical grinding machines. These machineries have granite bases that are not easily affected by vibration and thermal distortion. The stiffness of the construction and tight spindle systems enable outstandingly accurate carbide drill manufacturing.

Machine tool builders supply many options to fit all production needs. Universal cylindrical grinders are used to carry out both external and internal grinding processes. Production grinders maximize the throughput in high production volumes. CNC grinding machines are automatic and give repeatable operation.

Spindle systems. The most important part of high-precision cylindrical grinding machines is the spindle systems. Hydrostatic spindles are the most accurate, but also need complicated oil systems. At reduced costs, rolling element spindles offer satisfactory performance. Magnetic bearing systems allow contact friction to be removed, thereby extending spindle life.

Machine Type | Typical Accuracy | Production Rate | Best Application |

Universal Grinder | ±0.0002″ | 50-100 parts/hour | Job shop work |

Production Grinder | ±0.0001″ | 200-500 parts/hour | High volume |

CNC Grinder | ±0.00005″ | 100-300 parts/hour | Complex geometry |

The workholding systems should be able to meet the specific needs of carbide drill blanks. Magnetic fixtures are ideal for ferrous substances and will not retain carbide. Vacuum chucks offer strong non-magnetic retention capability. Collet systems have the highest accuracy on small diameter drills.

The temperature control systems ensure that there is no change in dimensions when grinding is taking place. Precision grinding is subject to serious dimensional changes due to thermal growth. The machine manufacturers install cooling mechanisms that ensure there is consistency in the temperatures during the grinding process.

CNC Grinding Machines for Carbide Drill Production

Computer-numeric-controlled grinding machines transform the production of carbide drill bits with automated precision. Such systems are computer-controlled and mechanically accurate to give repeatable results. The use of programming enables operators to develop intricate drill geometry, whose accuracy can be repeated.

The contemporary CNC grinding machines have several controlled axes to engage in the entire manufacturing of drills. Cross-feed movements are controlled by the X-axis, and longitudinal positioning is done using the Z-axis. Optional rotary axes allow helical flutes and complicated cutting geometries to be ground. Compound angles. Some machines are provided with B-axis tilting capability to allow compound angles.

Automatic tool changers also accelerate the production process since they do not require the time-consuming process of changing wheels manually. Various grinding applications demand a particular kind and size of wheel. CNC systems have the ability to automatically choose the right wheel for any given operation. That feature decreases set-up time and enhances run-to-run consistency.

The Benefits of a CNC Grinding Machine:

- Reproducibility of quality production run to production run.

- Computerized measuring and compensation devices

- Integration with quality control databases

- Shortened prep time across the drill sizes

- Enclosed grinding operations provide better safety, too.

Carbide drill bits’ grinding cycles are easy to develop with the aid of programming software. CAM systems result in grinding programs being generated directly from drill designs. Operators are able to do simulated grinding before they run real parts. The feature minimizes scrap and maximizes cycle times.

In-process measurement systems monitor dimensions during grinding. Laser measurement systems offer non-touch dimension checking. Such systems detect dimensional issues before they occur across a number of parts.

Key Factors in Carbide Drill Grinding Machine Selection

When choosing a grinding machine in the manufacturing of carbide drills, several factors need to be considered. The choice impacts the efficiency of production, the quality of the products, and profitability in the long run. The shrewd manufacturers consider all the factors in a very methodical manner in order to make a sound purchasing decision.

Production Volume Requirements for Carbide Drill Bits

The quantity of production plays a major role in the determination of the machines to use. The requirements of high-volume manufacturers differ severely from those of job shops that make small quantities. Knowing your production needs will allow you to narrow down the list of appropriate machines in a short time.

The manufacturers of large-scale carbide drills usually need Automated loading production grinders. In the name of increased throughput rates, these machines compromise flexibility. They are usually characterized by several grinding stations, which are able to carry out various actions at the same time. Robots decrease the number of labor expenses and ensure the consistency of quality in thousands of pieces.

Universal grinding machines that can deal with different part geometries and sizes are more useful to small-batch manufacturers. The advantage of these machines is that they are more flexible, but with the disadvantage of low production rates. Universal grinders have the ability to change to various carbide drill formats with a few setup alterations. This adaptability is useful in the manufacturing of special drill bits used in special applications.

Accuracy and Precision Standards for Cylindrical Grinding

Machine precision requirements are dictated by accuracy requirements. Aerospace carbide drill bits have closer tolerances than general-purpose tools. The machine manufacturers will give accuracy capabilities under certain conditions. Buyers ought to know these specifications, together with their relation to the reality of production needs.

Under controlled conditions, higher precision cylindrical grinding machines produce a tolerance of +/- 0.00005 inches. These machines have a temperature-controlled environment and a vibration isolation system. The cost of investing in precise machinery is recovered through the production of high-quality carbide drill bits, which have a higher pricing value. This precision is frequently needed by medical device makers to handle their special drilling uses.

The carbide drill bits’ tolerances in standard industrial use are normally within the range of +/- 0.0002 inches. This degree of precision is suitable for general manufacturing and building uses. The machines that fit these requirements are much less expensive than ultra-precision machines. The reduced investment enables the manufacturers to provide good competitive prices with sufficient quality.

Workpiece Size Range and Machine Capacity

The range of the size of workpieces influences the choice of the machine. Large diameter tools need different workholding solutions than small diameter drills. The size of the workpiece that can be accommodated in the machine throat is limited. When choosing machines, buyers are supposed to take into consideration future product needs.

Microcarbide drill bits less than 1mm in diameter require special fixtures and high-speed spindles. These are very small tools, and so very delicate handling is needed during grinding to avoid breakage. Special collet chucks offer positive, non-destructive holding with a minimum of clamping force. Pixel Vision Systems aids the operator in closely monitoring the grinding process.

Extra-large diameter carbide drill bits above 25mm diameter need heavy-duty workholding and high-powered grinding spindles. These tools cut high forces that may result in vibration issues. Grinding operations are not subject to deflection because of heavy-duty machine bases and stiff spindle systems. Bigger machineries also require stronger coolant systems to dissipate the heat.

Budget Considerations and Total Cost Analysis

Budget implications can be composed of purchase price and operating costs. The expensive machines have high precision, which might justify themselves in the long term. The operating costs are maintenance, tooling, and energy consumption. The total cost of ownership calculations assist in making effective decisions.

The initial cost of equipment depends on the accuracy needed and the level of automation required, and can differ greatly. The small manual cylindrical grinders begin at $50,000. The price of CNC grinding machines is around 200,000-500,000 dollars, depending on abilities. Special applications of ultra-precision machines may cost more than 1 million dollars.

The cost of operation will, in most cases, surpass the purchase price throughout the lifetime of the machine. Energy costs, coolant systems, and grinding wheel prices accumulate rapidly. Maintenance cost involves spindle rebuilds, way repair, and electronic system updates. To find the real value of equipment, smart buyers amortize those costs over 10-15 years.

Machine Selection Checklist for Carbide Drill Grinding

- Diameter and length capabilities of the workpiece of current and future products.

- Application require

- The volume and cycle time production needs to meet business forecasts, compatibility of workholding systems with carbide materials, and drill geometries.

- Dressing and mounting of grinding wheels of various types available

- Carbide grinding coolant system capacity and filtration. Carbide grinding requires substantial coolant system capacity and filtration.

- The level of skill of the operator and the training needed to use it successfully.

- Floor space and utility needs, such as power and compressed air, will be available.

Conclusion

The choice of cylindrical grinding equipment and processes is important in manufacturing high-quality carbide drill bits. Modern CNC grinding machines have provided new levels of precision and repeatability in drill manufacture. The cost of investing in the right grinding technology is repaid in better performance of the tools and customer satisfaction.

To be successful in the manufacture of carbide drills, one has to understand the basics of grinding, the capabilities of machines, and their selection. Advanced precision cylindrical grinding machines help manufacturers have a chance to compete in such challenging markets as aerospace and medical devices. A right mix of equipment, operators, and process makes profitable carbide drill operations.

Prudent manufacturers are particular about their needs before investing in grinding equipment. When deciding on the equipment, consider the volume of production, accuracy needs, and long-term business objectives. The appropriate cylindrical grinding system will turn rough carbide blanks into finished cutting tools that will surpass the expectations of the customers.