Get in touch with HUANA

Any information about OEM Supply Delivery contact

We usually reply your message within 3 bussiness hours.

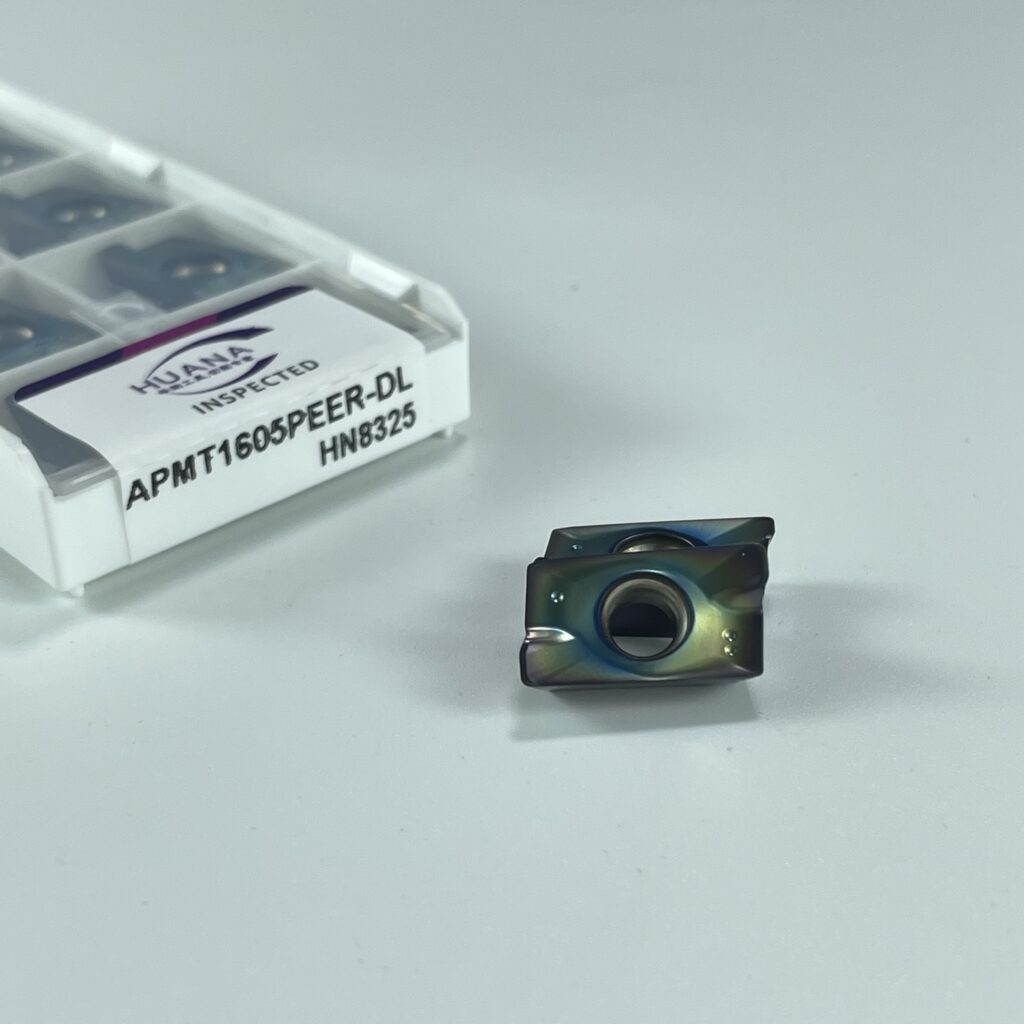

DLC COATING milling turning tools

Groove design for reducing cutting resistance;

harden Alloy material for stronger wear resistance;

Upgrade grinding craft for higher precision

Different R angles meet your finishing and roughing turning needs to reduce cutting resistance to achieve sharp cutting.

Paypal, T/T, West Union, Bank Transfer.

Fedex(best), DHL, UPS, EMS, etc.

For samples , we dispatch your tools in 2-7 workdays .

For formal orders,We delivery tools to you in 7-15 workdays , it will depond on your order quantity .

Yes, we provide free samples, and support ODM&OEM (labeling, marking, packing box)

We usually reply your message within 3 bussiness hours.